EGR control system for internal combustion engine instantaneous conditions

A technology for transient operating conditions and control systems, applied in engine control, mechanical equipment, machines/engines, etc., can solve the problems of not achieving comprehensive optimization of smoke and NOx, deterioration of NOx emissions, etc., and improve the trade-off relationship. , the effect of reducing harmful emissions and NOx emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

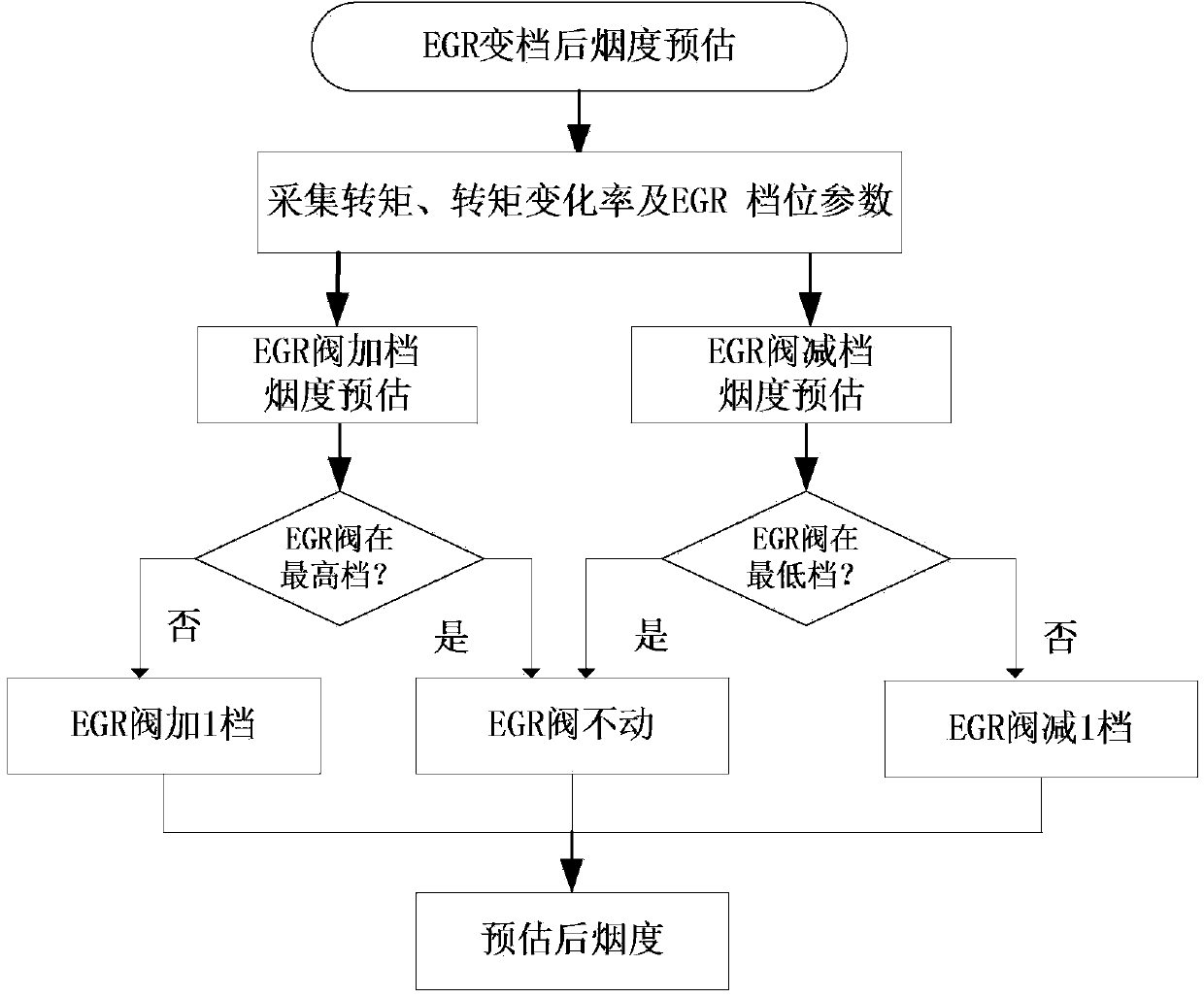

[0041] refer to figure 1 , an EGR control system for an internal combustion engine under transient conditions, comprising an internal combustion engine 1, an intake manifold 2 and an exhaust manifold 18 connected to the internal combustion engine 1, a high-response rotational speed sensor 3 and a high-response torque sensor 4 arranged on the internal combustion engine 1, Air intake intercooler 5, electronic control unit ECU6, EGR intercooler 7, filter 8, four high-response electronically controlled EGR valves 9, 10, 11, 12, air filter 13, intake tee pipe 14 , compressor 15, turbine 16, tee pipe 17;

[0042]The inlet of the three-way pipe 18 is connected with the discharge main pipe 18, and the two outlets are respectively connected with the inlets of the turbine 16 and the EGR intercooler 7, and the inlet of the filter 8 is connected with the outlet of the EGR intercooler 7 The four high-response electronically controlled EGR valves 9, 10, 11, 12 are connected to the outlet ...

experiment example 1

[0051] The detailed working process under the transient condition with loading time of 2s is as follows:

[0052] (1) First, according to the actual needs of the smoke control target and the test calibration value, set the upper limit value of the smoke level, the upper limit value of the smoke level control area and the lower limit value of the smoke level control area in the electronic control unit (ECU) 6 . In this embodiment, the upper limit value of smoke is 10% (extinction smoke value), the upper limit of smoke control area is 8%, and the lower limit of smoke control area is 4%;

[0053] (2) Electronic control unit (ECU) 6. Collect the speed, torque and EGR gear signal of the diesel engine. When the torque transient rate of the engine is detected to be 278N.m·s -1 , it is determined that the engine is in a transient condition, and the following commands are quickly executed:

[0054] (3) The electronic control unit (ECU) 6 estimates the rapid smoke value according to th...

experiment example 2

[0059] The detailed working process under the transient condition with loading time of 10s is as follows:

[0060] (1) First, according to the actual needs of the smoke control target and the test calibration value, set the upper limit value of the smoke level, the upper limit value of the smoke level control area and the lower limit value of the smoke level control area in the electronic control unit (ECU) 6 . In this embodiment, the upper limit value of smoke is 10% (extinction smoke value), the upper limit of smoke control area is 8%, and the lower limit of smoke control area is 4%;

[0061] (2) Electronic control unit (ECU) 6. Collect the speed, torque and EGR valve opening signal of the diesel engine. When the torque transient rate of the engine is detected to be 55.6N.m·s -1 , it is determined that the engine is in a transient condition, and the following commands are quickly executed:

[0062] (3) The electronic control unit (ECU) 6 estimates the quick smoke value acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com