Plant-mixing cold-recycling foamed bituminous mixture production system

A technology of foamed asphalt and production system, which is applied in the direction of roads, road repairs, roads, etc., can solve the problems of affecting the construction progress, large dependence, and mismatching construction capabilities, so as to improve the construction quality, improve the performance of the mixture, and improve the asphalt The effect of foaming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

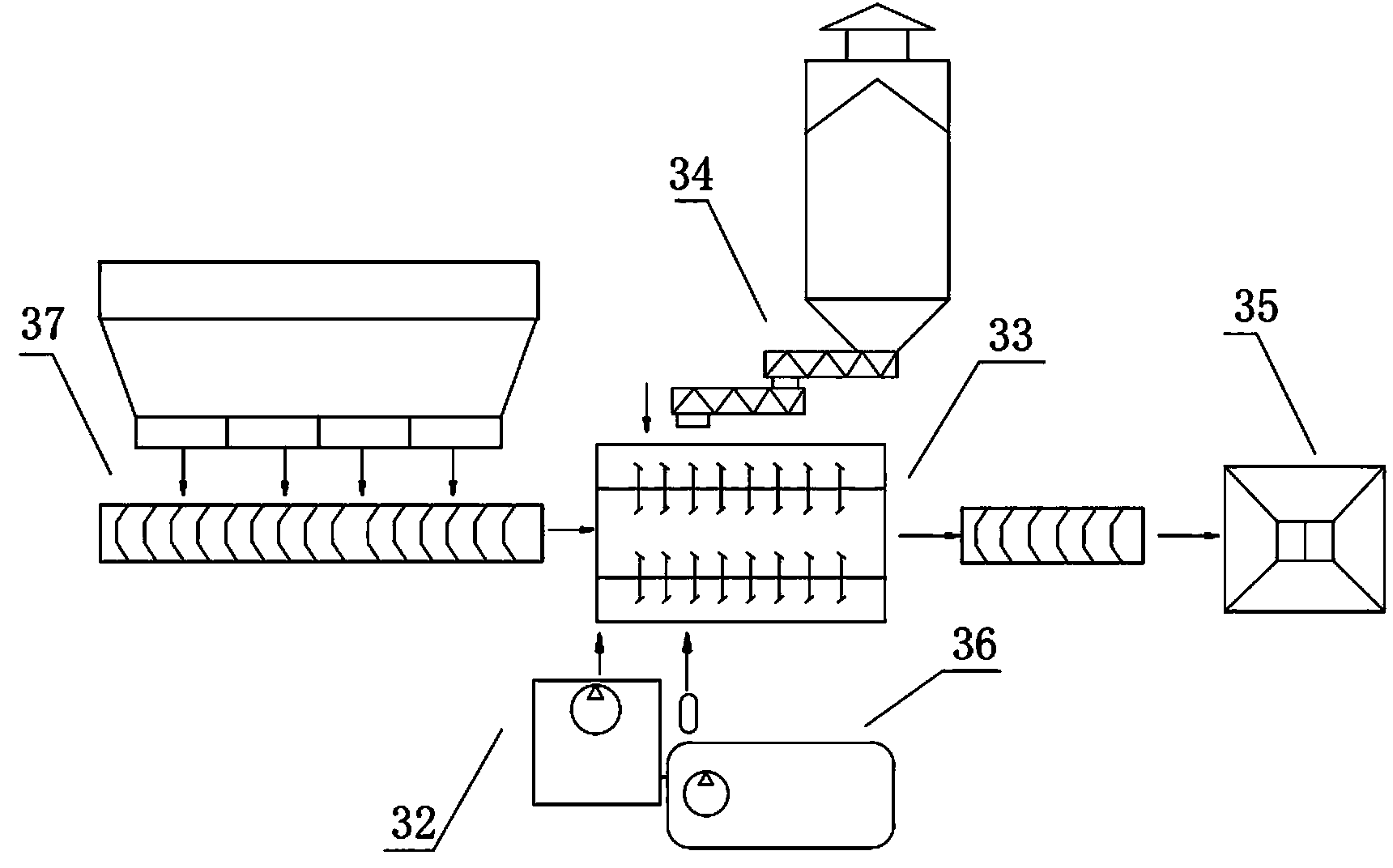

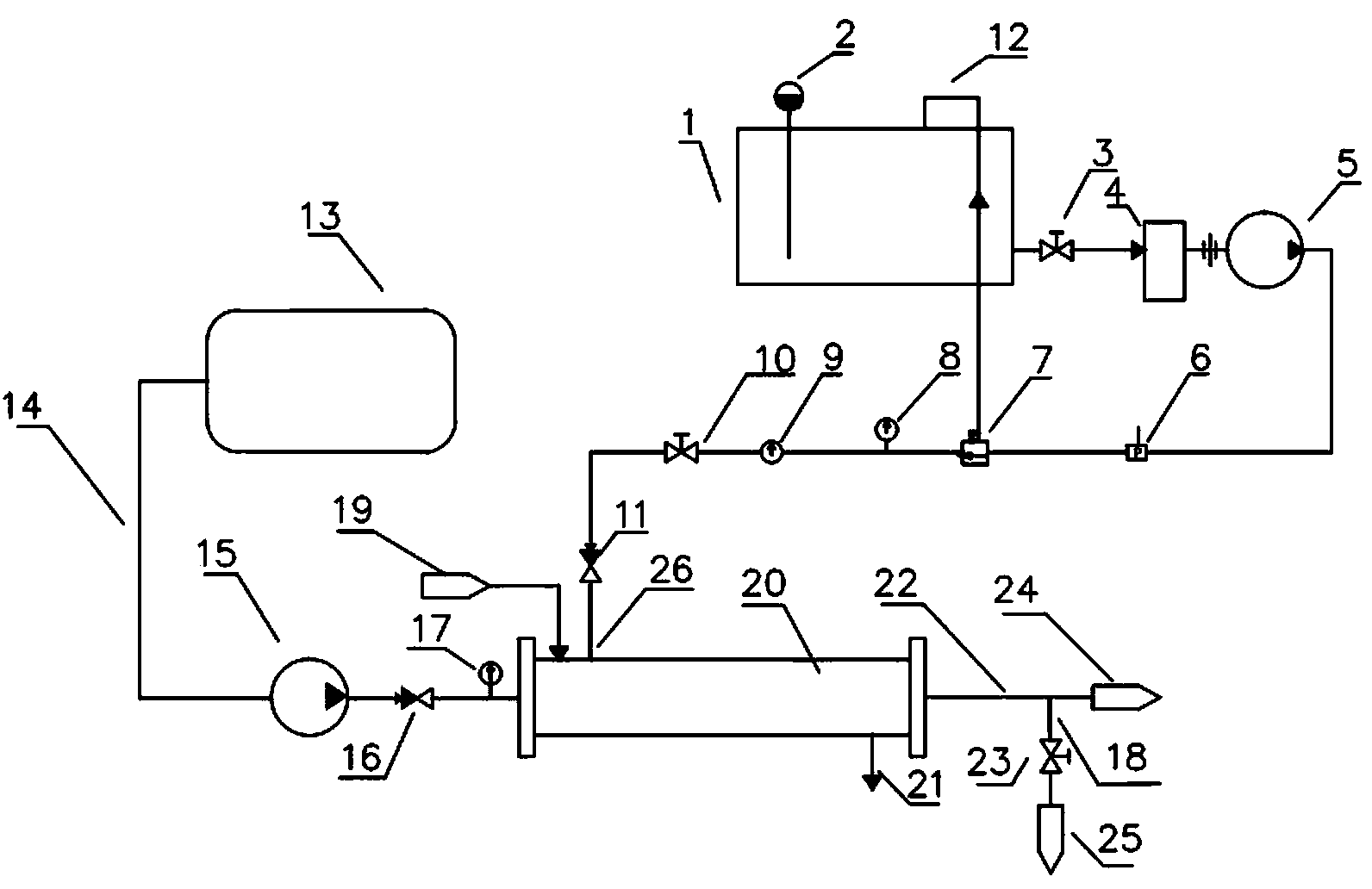

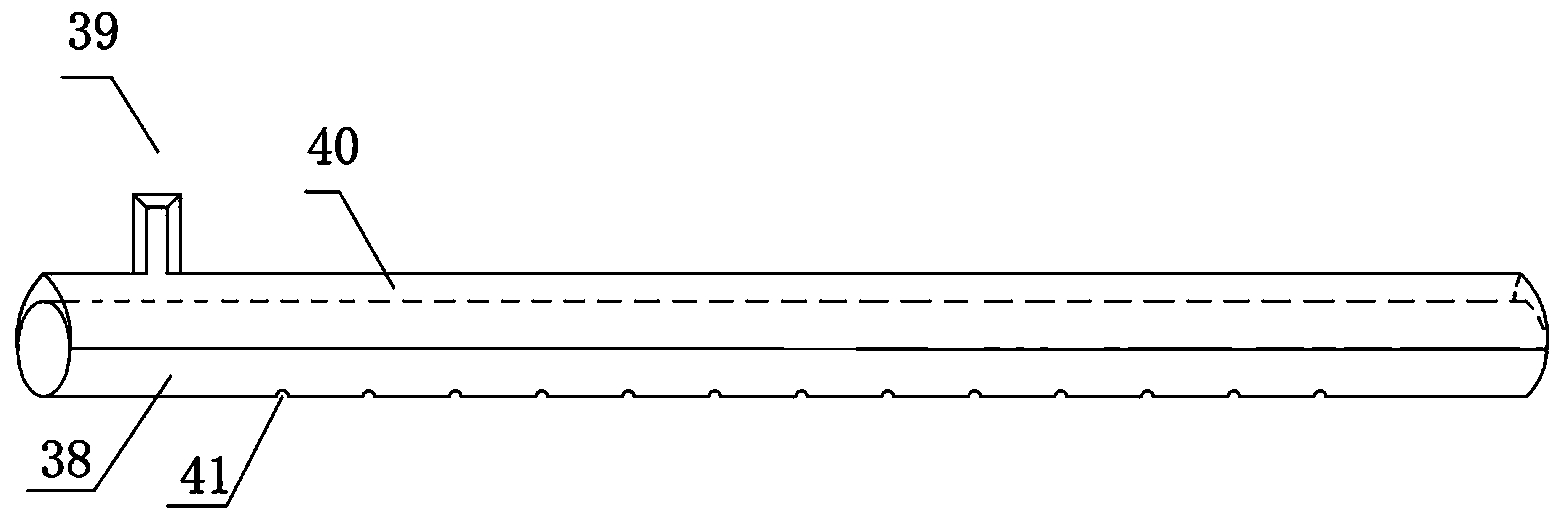

[0023] Depend on figure 1 It can be seen that the present invention includes stabilized soil factory mixing equipment and asphalt foaming device 36, and the asphalt injection pipe 24 of the asphalt foaming device 36 communicates with the stirring device 33 of the stabilized soil factory mixing device. Existing stabilized soil plant mixing equipment comprises aggregate batching supply metering device 37, water supply device 32, stirring device 33, powder material supply metering device 34 and material storage device 35, described aggregate batching supply metering device 37, powder material supply The metering device 34 is connected to the stirring device 33, the water supply device 32 is connected to the stirring device 33, the stirring device 33 is connected to the material storage device 35, and the asphalt foaming device 36 is an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com