A kind of spinning method for fiberizing the sliver

A technology of beard and spinning frame, applied in the field of textile processing, which can solve the problems of adding fiber control devices, high energy consumption of compact spinning, and reducing fiber utilization, so as to avoid outward diffusion and large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

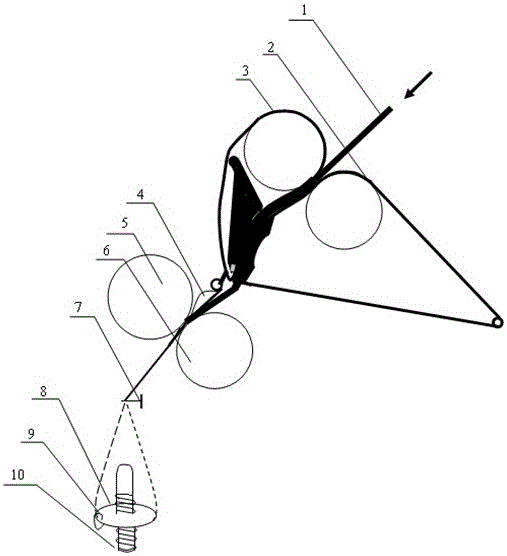

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings. see Attachment

[0018] A spinning method for fiberizing strands, in which a fiberizing treatment device 4 is installed on the distance block or the cradle in the front drafting area of the ring spinning frame, and the strands 1 pass through the lower apron 2 and the gluing The gripping jaws composed of rings 3 are input into the fiber-refining processing device 4, and the strands 1 after being collected and autoleveled by the fiber-refining processing device 4 are output from the front jaw composed of the front roller 5 and the front roller 6. Through guide hook 7, steel ring 8, steel traveler 9, be wound on the spinning bobbin 10.

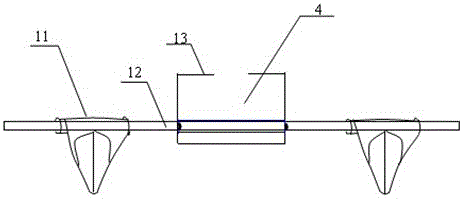

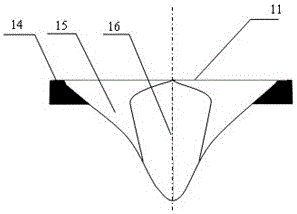

[0019]The fiber straightening device 4 is composed of a fiber straightening device 11, a support shaft 12 and a support 13, the support shaft 12 is cylindrical, the support 13 is fixedly connected to the middle position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com