Coating machine crucible device

A coating machine and crucible technology, applied in the field of coating machine crucible equipment, can solve problems such as large temperature difference and unstable evaporation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

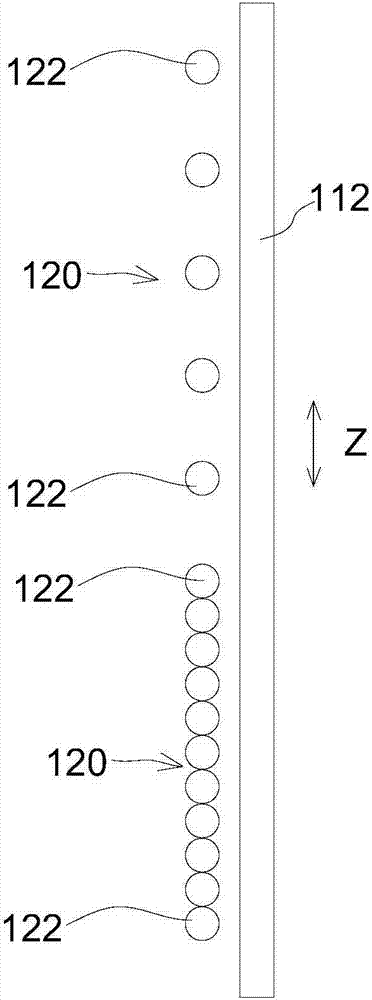

[0019] like figure 1 As shown, the coating machine crucible device 100 of this embodiment includes a barrel structure 112 , a plurality of heaters 120 , a crucible 110 , a plurality of temperature sensors 160 and a plurality of driving mechanisms 200 . Wherein, the plurality of heaters 120 are distributed in the barrel structure 112 along the longitudinal direction Z and are used to heat the materials contained in the crucible 110 . The plurality of temperature sensors 160 are distributed in the crucible 110 along the longitudinal direction Z to measure the temperature of different longitudinal regions of the crucible 110 . The multiple driving mechanisms 200 are used to move at least one heater 120 among the multiple heaters 120 along the longitudinal direction Z to control the temperature distribution in the crucible 110 . In this way, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com