Densifier and fracturing fluid for shale gas fracturing fluid, preparation method and application thereof

A thickening agent and fracturing fluid technology, which is applied in chemical instruments and methods, earthwork drilling, and fluid production, etc., can solve the problems of high cost, reduced sand carrying capacity, and few continuous mixing devices, etc., and achieves low friction. resistance, high-efficiency viscosity-increasing properties, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] 1. Preparation of key additives for fracturing fluid

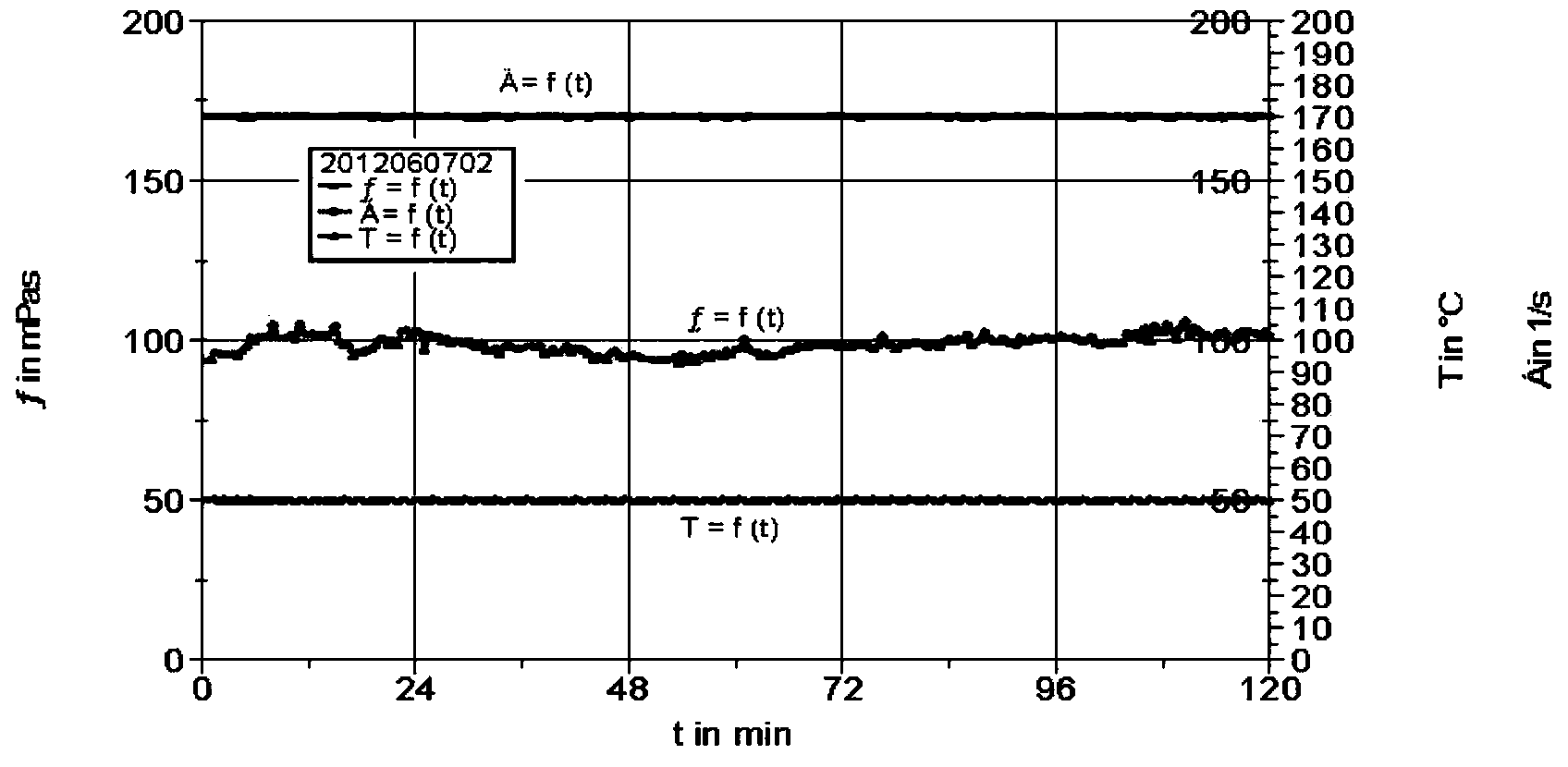

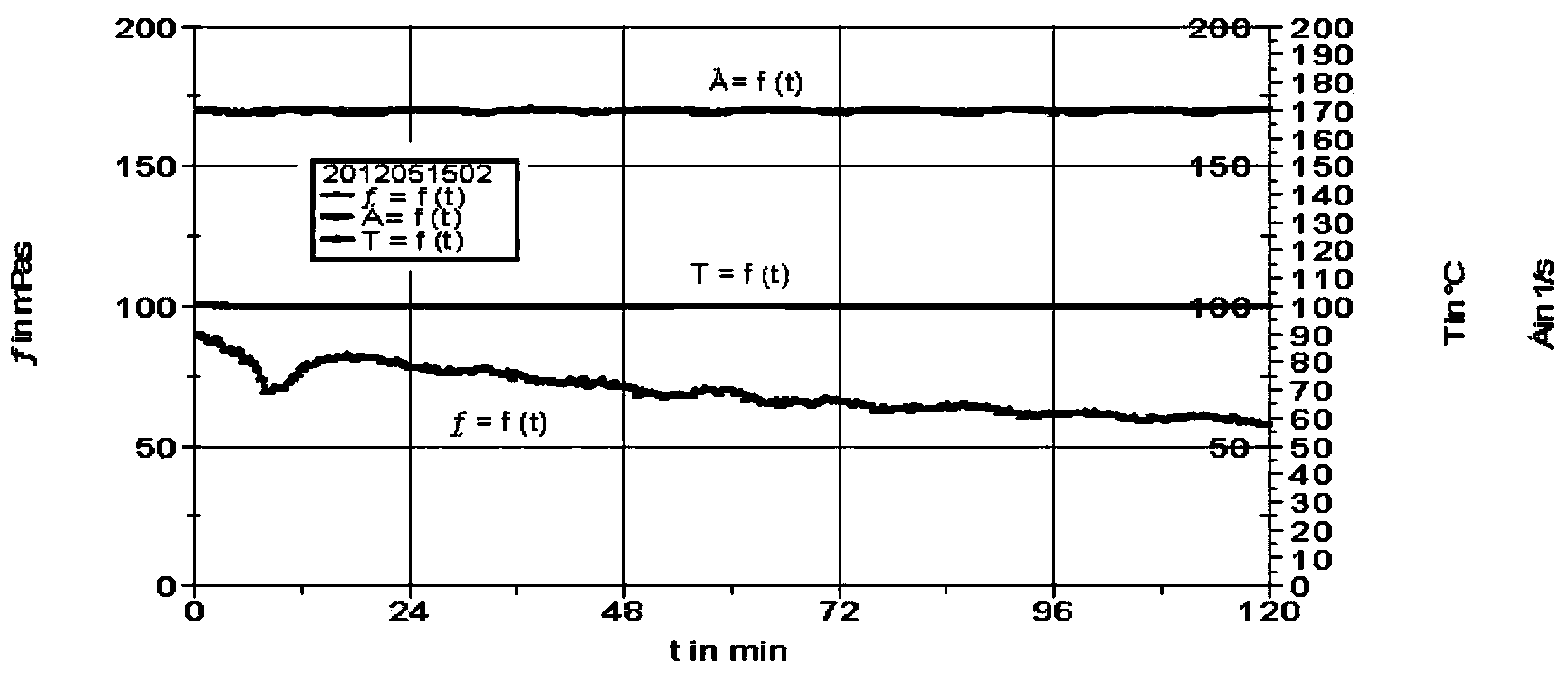

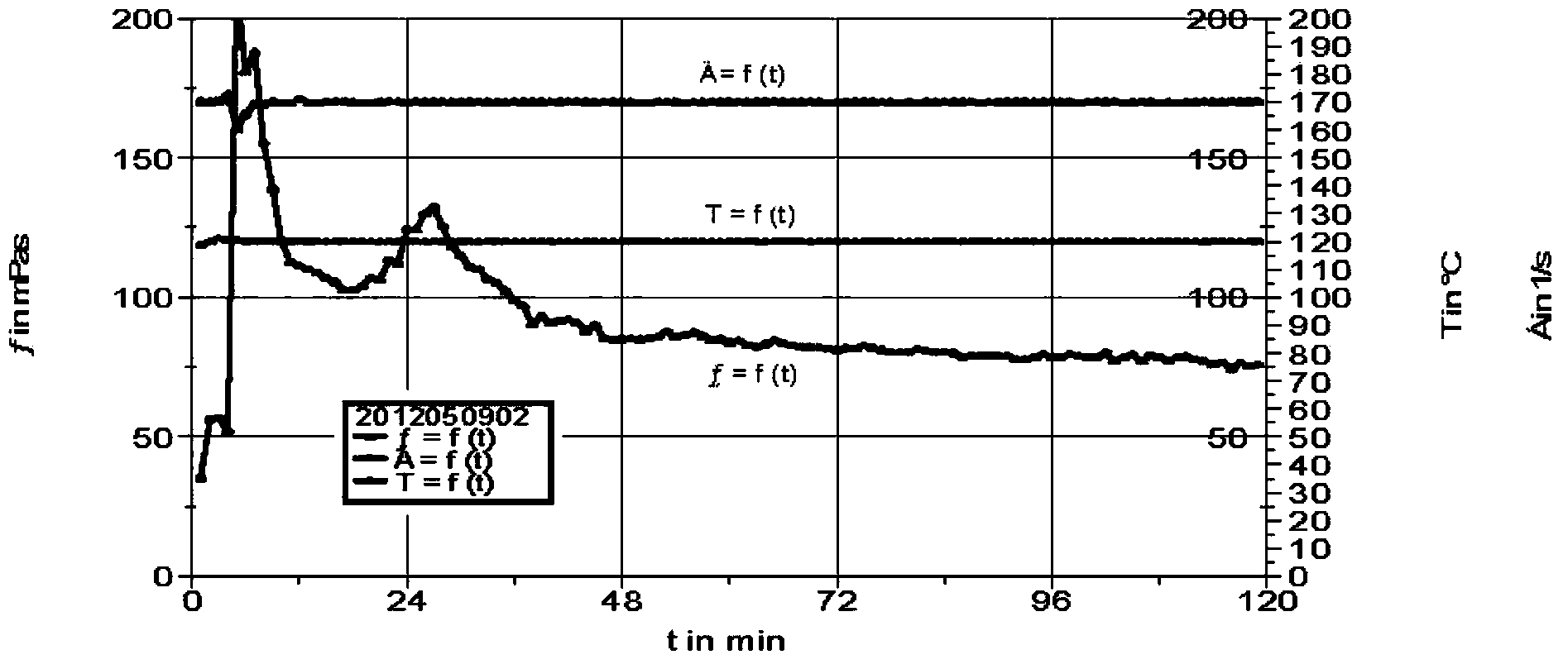

[0049] 1.1 Thickener DH-DB-1

[0050] The thickening agent in this embodiment is composed of viscoelastic surfactant (benzalkonium chloride), polyacrylamide, AMPS, methacryloxytrimethylammonium chloride, N-isopropylacrylamide, pimeloyl , caustic soda etc. are synthesized according to the volume ratio of 3:6:0.5:1.5:2:2:1, and the specific synthesis method is as follows:

[0051] Mix the viscoelastic surfactant with the polyacrylamide resin and heat it to melt completely, then add 2-acrylamido-methylpropanesulfonic acid, methacryloxytrimethylammonium chloride, N-isopropyl Acrylamide, pimeloyl, and caustic soda were stirred and reacted at 150°C for about 2 hours, and the product obtained was the thickener of this embodiment. After cooling to normal temperature, it was a solid product, and it was crushed to obtain a crystal powder, which was used for liquid thicken. The present invention calls the thickener DH-DB-1 ...

Embodiment 2

[0138] DH-DB active fracturing fluid has the construction capability of continuous mixing on site, which can meet the requirements of 8-10m sand mixing truck 3 / min construction displacement requirements.

[0139] According to different reservoir temperatures, determine the ratio of each additive, according to the order of adding additives DH-DB-1→DH-DB-2→DH-DB-3→ammonium persulfate, add to the mixing tank of the continuous mixing vehicle, and prepare the liquid supply Sand mixer. The prepared liquid is sent to the wellhead through the sand mixer truck, and finally enters the formation.

[0140] In the absence of a continuous mixing vehicle, the preparation method of large-displacement jet flow circulation can be adopted, which can also meet the requirement of providing 8-10m 3 / min construction displacement requirements. The order of additive addition is the same as for continuous compounding.

[0141] Field application

example 1

[0143] Well Test 3 is a shutdown well, the target layer is Mountain 1, the reservoir temperature is 90°C, and the fractured interval is 2622.0-2626.0m. HPG cross-linked jelly was used for primary fracturing, with an average sand ratio of 21.6% and sand addition of 35.1m 3 , stop pump pressure 27MPa. After fracturing, 3.0mm, 4.0mm, and 5.0mm nozzles were used to control the spraying and drainage, and the spraying and drainage was opened later. The flowback rate of the fracturing fluid was 72.83%. Using one-point method to calculate production, the average stable gas production is 0.6400×10 4 m 3 / d, average water production 0.13m 3 / d, the calculated unimpeded flow is 2.1533×10 4 m 3 / d. The fracturing effect is poor.

[0144] Select DH-DB active CO for repeated fracturing 2 For foam fracturing fluid construction, the fracturing fluid (0.6% thickener DH-DB-1+0.4% rheology additive DH-DB-2) and CO 2 In different proportions (CO 2 The mass ratio of foam is less than 30%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com