Cellulose micro-sphere with uniform size as well as preparation method and application thereof

A technology of cellulose microspheres and cellulose, applied in the direction of microsphere preparation, microcapsule preparation, chemical instruments and methods, etc., can solve the problems of limited application range, uneven particle size of cellulose microspheres, etc., and achieve good repeatability , Conducive to environmental protection, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

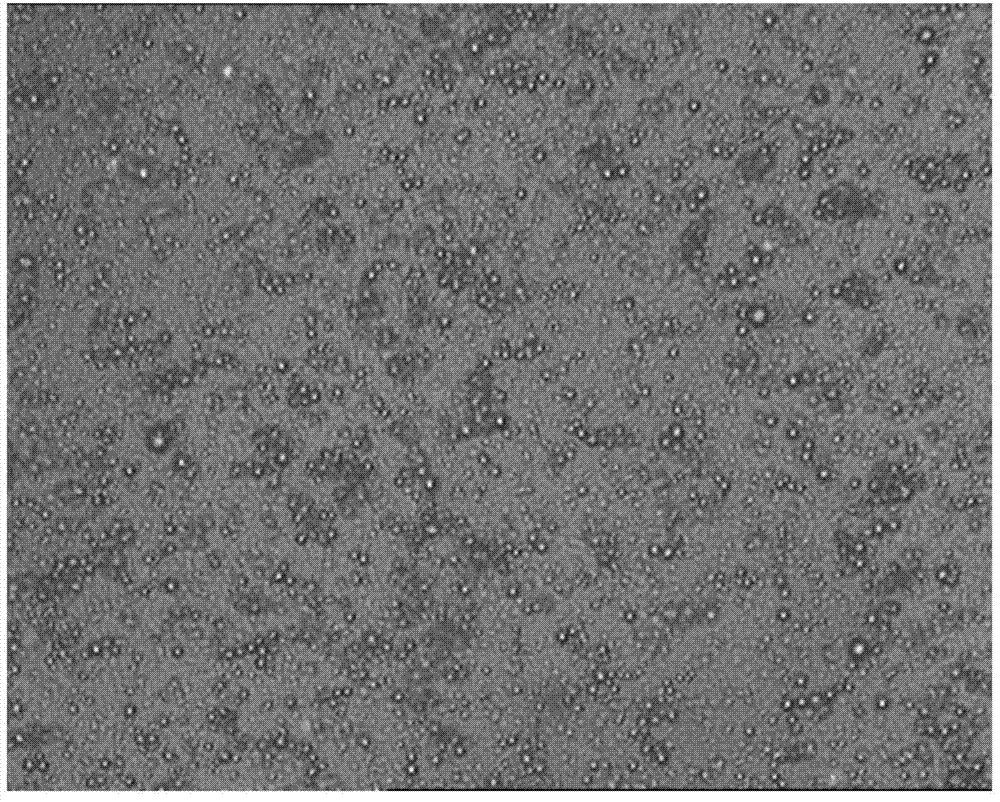

Image

Examples

preparation example Construction

[0026] The preparation process of cellulose microspheres is as follows:

[0027] Dissolving cellulose in alkali / urea aqueous solution or alkali / thiourea aqueous solution at -12 to -5°C, centrifuging to defoam and remove impurities to obtain a cellulose solution as the water phase.

[0028] The oil-soluble emulsifier is dissolved in the oily liquid at a volume ratio of 0-10% as the oil phase. Wherein, the oil-soluble emulsifier is selected from any one of Span 80, Span 60, Tween 80, oleic acid, and potassium oleate or mixed arbitrarily; or no emulsifier is added. The oily liquid is any one or any mixture of kerosene, transformer oil, pump oil, 200# gasoline, turbine oil, liquid paraffin, petroleum ether, soybean oil, rapeseed oil.

[0029] Take the oil phase: the volume ratio of the water phase is 1:3-1:25, and press the water phase into the oil phase through the hydrophobic porous membrane to obtain the W / O emulsion; under the condition of stirring, add the solidification liq...

Embodiment 1

[0034] The hydrophobic membrane with a pore size of 0.3 μm is immersed in a lipophilic substance to fully wet the porous membrane to ensure that the hydrophobic chains on the membrane are completely stretched. Precool NaOH / urea aqueous solution to -12°C as a solvent to dissolve cellulose and centrifuge to defoam and remove impurities to prepare a cellulose solution with a concentration of 4wt%. Stir 2.4ml of the above cellulose solution for 30 minutes and sonicate for 10 minutes as the water phase spare. Add 6ml of Span 80 into 60ml of the mixed oil phase of liquid paraffin and petroleum ether, and stir until completely dissolved as the oil phase. Press 2.4ml of the water phase into the oil phase through a hydrophobic microporous membrane with uniform pore size under constant pressure to obtain a W / O emulsion. A certain amount of dilute hydrochloric acid solidification solution was slowly added dropwise to the obtained emulsion at a rotational speed of 600 rpm, and the solidi...

Embodiment 2

[0036] The hydrophobic membrane with a pore size of 1 μm is soaked in a lipophilic substance, so that the porous membrane is fully wetted to ensure that the hydrophobic chains on the membrane are completely stretched. Use NaOH / urea aqueous solution to pre-cool to -12°C as solvent to dissolve cellulose and centrifuge to defoam and remove impurities to prepare a cellulose solution with a concentration of 4wt%. Stir 7ml of the above cellulose solution for 30 minutes, ultrasonic for 10 minutes, and use it as the water phase for later use . Add 2.5ml of oleic acid / potassium oleate compound emulsifier into 60ml of the mixed oil phase of liquid paraffin and gasoline, and stir until completely dissolved as the oil phase. Press 7ml of the water phase into the oil phase through a hydrophobic microporous membrane with uniform pore size under constant pressure to obtain a W / O emulsion. A certain amount of dilute hydrochloric acid solidification solution was slowly added dropwise to the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com