Preparation method of porous BN/Si3N4 composite ceramic hole sealing layer

A composite ceramic and hole sealing technology, which is applied in the field of surface sealing technology of porous BN/Si3N4 composite ceramics, can solve the problems of difficulty in meeting the requirements of high temperature use and great influence on dielectric properties, and achieves low cost, increased use temperature, Equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

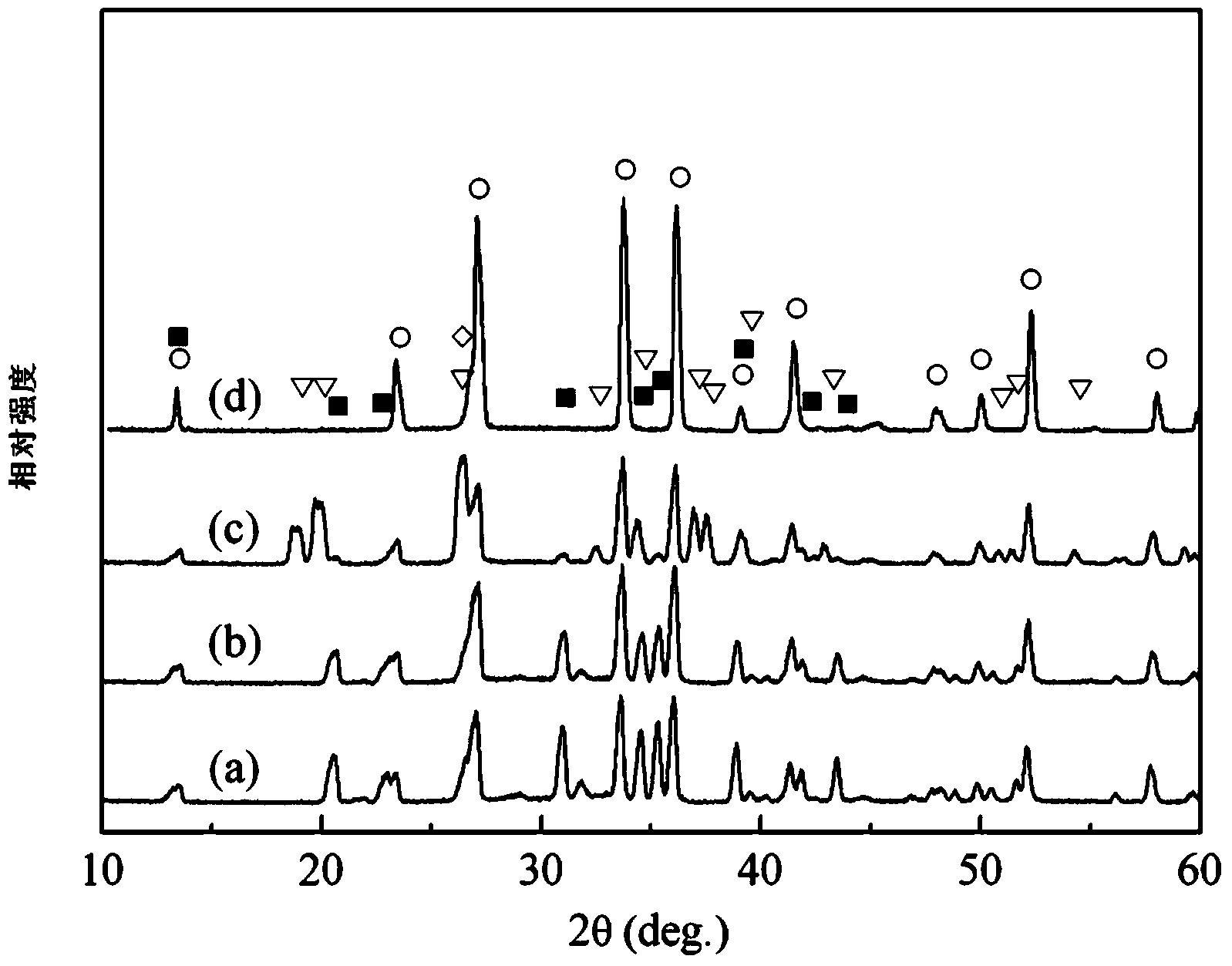

Image

Examples

specific Embodiment approach 1

[0031] Specific implementation mode 1: In this implementation mode, a porous BN / Si 3 N 4 The preparation method of the composite ceramic sealing layer is specifically carried out according to the following steps:

[0032] 1. Mix the ceramic powder and sintering aid evenly to obtain a mixed powder, wherein the ceramic powder is Si 3 N 4 Powder and SiO 2 Mixture of powders, Si 3 N 4 Powder and SiO 2 The molar ratio of the powder is 0.5-1.5, and the amount of sintering aid added is 5%-15% of the mass of the ceramic powder;

[0033] 2. Add the wetting agent and dispersant to deionized water to obtain a premixed solution, then adjust the pH value of the premixed solution to 8.5-10.5, then add the mixed powder obtained in step 1, and then ball mill and mix to obtain a sealing slurry. Control the solid phase volume content of the sealing slurry to 5-25%; among them, the amount of dispersant added is 0.2%-0.6% of the mass of ceramic powder, and the amount of wetting agent added...

specific Embodiment approach 2

[0036] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the sintering aid in step one is Al 2 o 3 and Y 2 o 3 mixture of Al 2 o 3 The average particle size is 100nm, Y 2 o 3 The average particle size is 50nm, Al 2 o 3 with Y 2 o 3 The volume ratio is 1:2. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0037] Specific embodiment three: the difference between this embodiment and specific embodiment one is: Si in step one 3 N 4 The average particle size of the powder is 0.5μm, SiO 2 The average particle size of the powder was 0.7 μm. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com