Control method for heating output of continuous annealing production line

A technology of output control and de-production line, which is applied in the field of cold-rolled strip steel, can solve the problems of thin-gauge strip steel that is prone to hot buckling, etc., and achieve the effect of improving the ability of stable plate passing, improving product quality, and realizing stable plate passing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

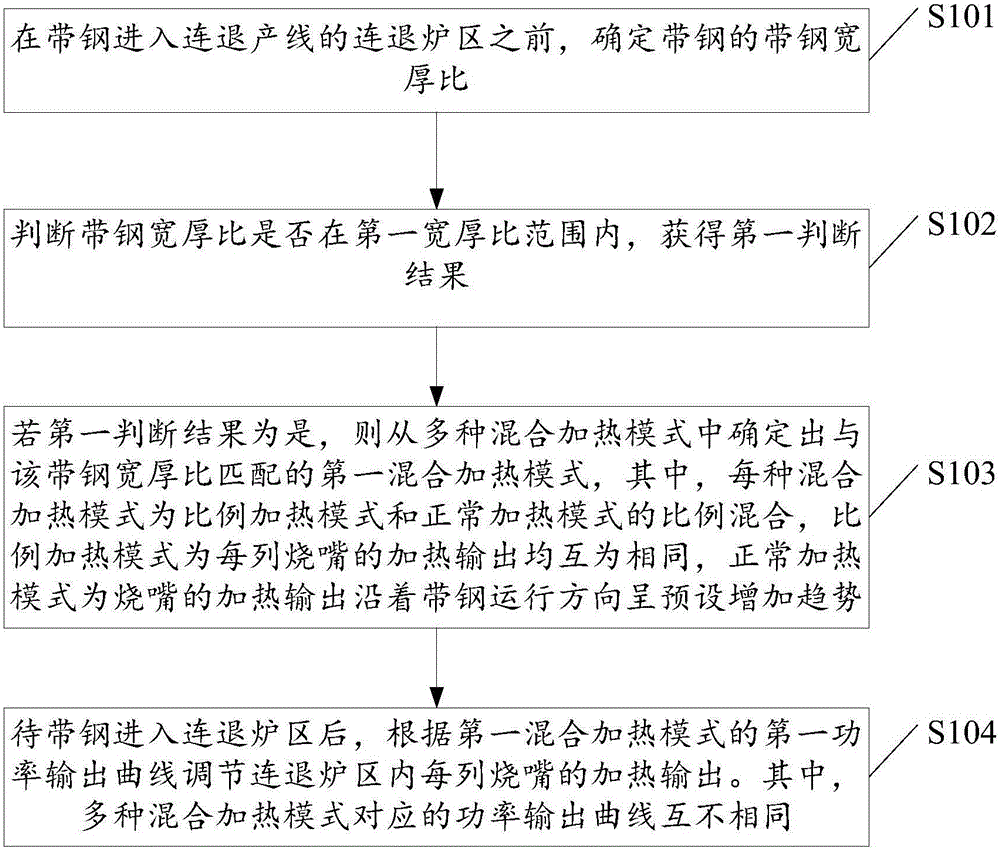

[0021] In order to solve the technical problem in the prior art that thin-gauge steel strips are prone to hot buckling in the continuous annealing furnace, the embodiment of the present invention provides a heating output control method for the continuous annealing production line. The general idea is as follows:

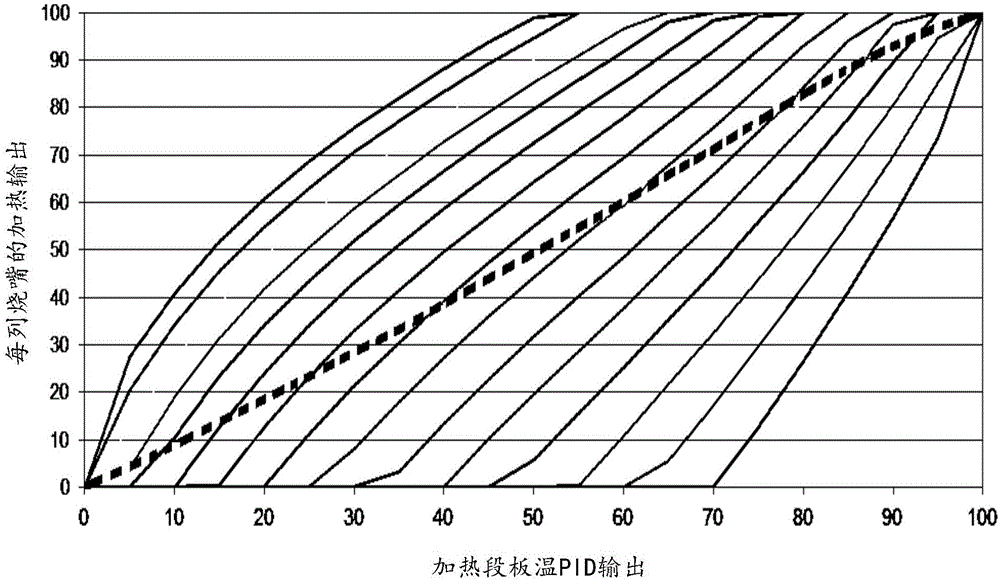

[0022] Before the strip steel enters the continuous annealing furnace area of the continuous annealing production line, the matched first mixed heating mode is determined according to the width-thickness ratio of the currently produced strip steel, and after the strip steel enters the continuous annealing furnace area of the continuous annealing production line, Adjust the heating output of each row of burners in the continuous annealing furnace area according to the power output curve of the first mixed heating mode. Make the heating output of the heating section change according to the width-to-thickness ratio specification of the strip steel, prevent the thin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com