Large container ship guide rail frame and welding process thereof

A technology of container ship and welding process, applied in welding equipment, ship construction, ship accessories, etc., can solve the problem of uncontrollable deformation of angle steel, and achieve the effect of reducing welding time, improving welding efficiency and ensuring flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

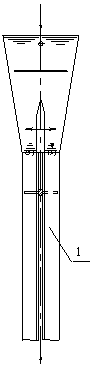

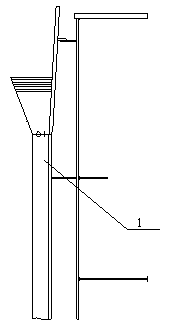

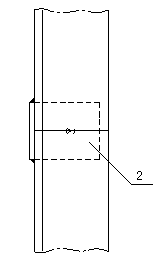

[0022] Such as figure 1 , 2 , shown in 3 and 4, a kind of guide rail frame of large-scale container ship, comprises guide rail frame body: described guide rail frame body upper end 1 trapezoidal inlet form: is fixedly connected by a backboard and a sub-guide block; described guide rail frame body middle 2 Butt joint form: it is fixed and supported by a backing plate; the lower end of the guide rail frame body 3: it is bent and opened by angle steel to form the import form of the container foot. The back plate is higher than the top plate of the hatch coaming.

[0023] Welding process of guide rail frame of large container ship:

[0024] 1) A backplane and a sub-guide block are fixedly connected to form an upper trapezoidal inlet;

[0025] 2) One side of the equilateral angle steel at the docking node in the middle of the guide rail frame body is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com