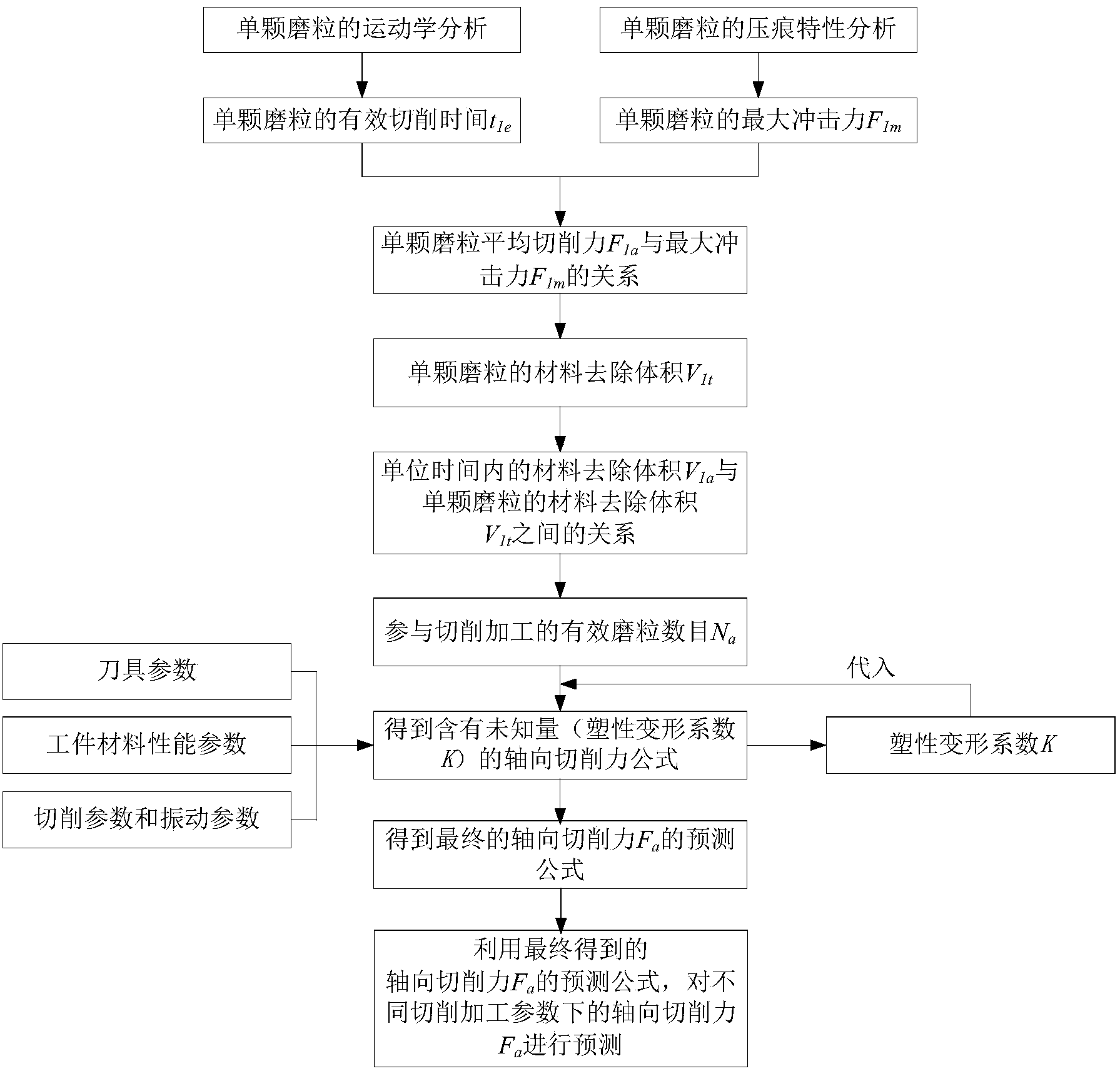

Method for predicting axial direction cutting force of supersonic vibration auxiliary grinding for fragile materials

A technology of cutting force prediction and ultrasonic vibration, which is applied to the control of parts of grinding machine tools, grinding/polishing equipment, and workpiece feed movement, and can solve problems such as not being able to reflect processing conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

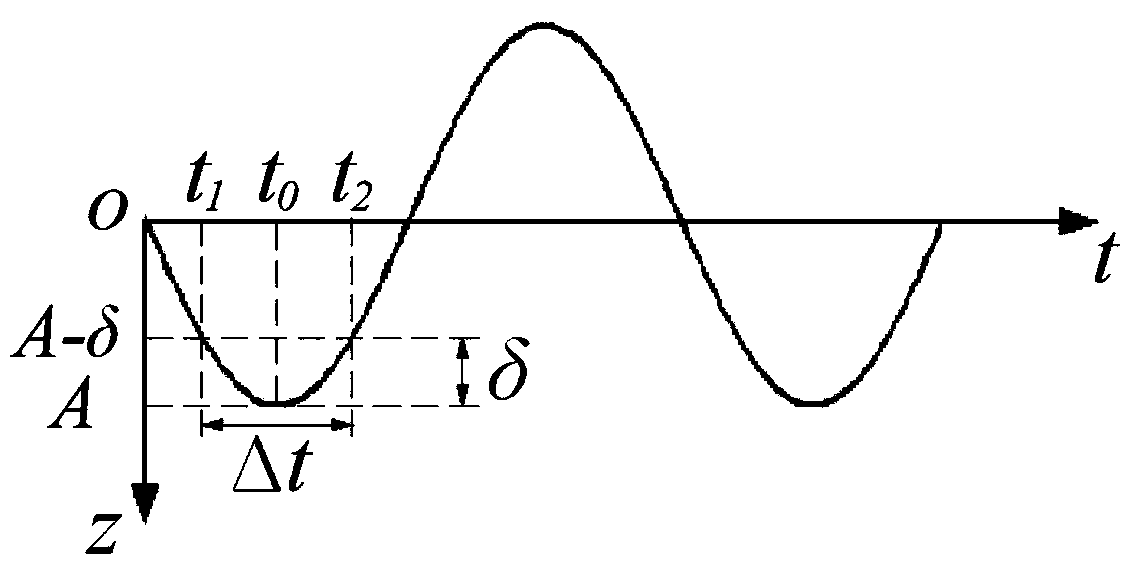

[0046] The axial cutting force prediction method for ultrasonic vibration-assisted grinding of brittle materials of the present invention is suitable for ultrasonic vibration-assisted grinding of brittle materials such as ceramics and glass. In this embodiment, the ultrasonic vibration-assisted grinding of zirconia ceramics is used as For example, its processing form is as figure 2 As shown, the tool used is a hollow tool with diamond abrasive grains, the tool rotates with the spindle and vibrates at an axial ultrasonic frequency, and the tool performs a feed motion. In the figure, the number 1 indicates diamond abrasive grains, and the number 2 indicates the machined surface of the workpiece material. The specific parameters of diamond abrasive grain tools, the main performance parameters and vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com