Rectangular pipe and production process thereof

A production process and technology for rectangular tubes, applied in the field of rectangular tubes, can solve the problems of interfering with data transmission, affecting the rigidity of the USB shell structure, lack of mass production of seamless tubes, etc., and achieving the effect of good performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

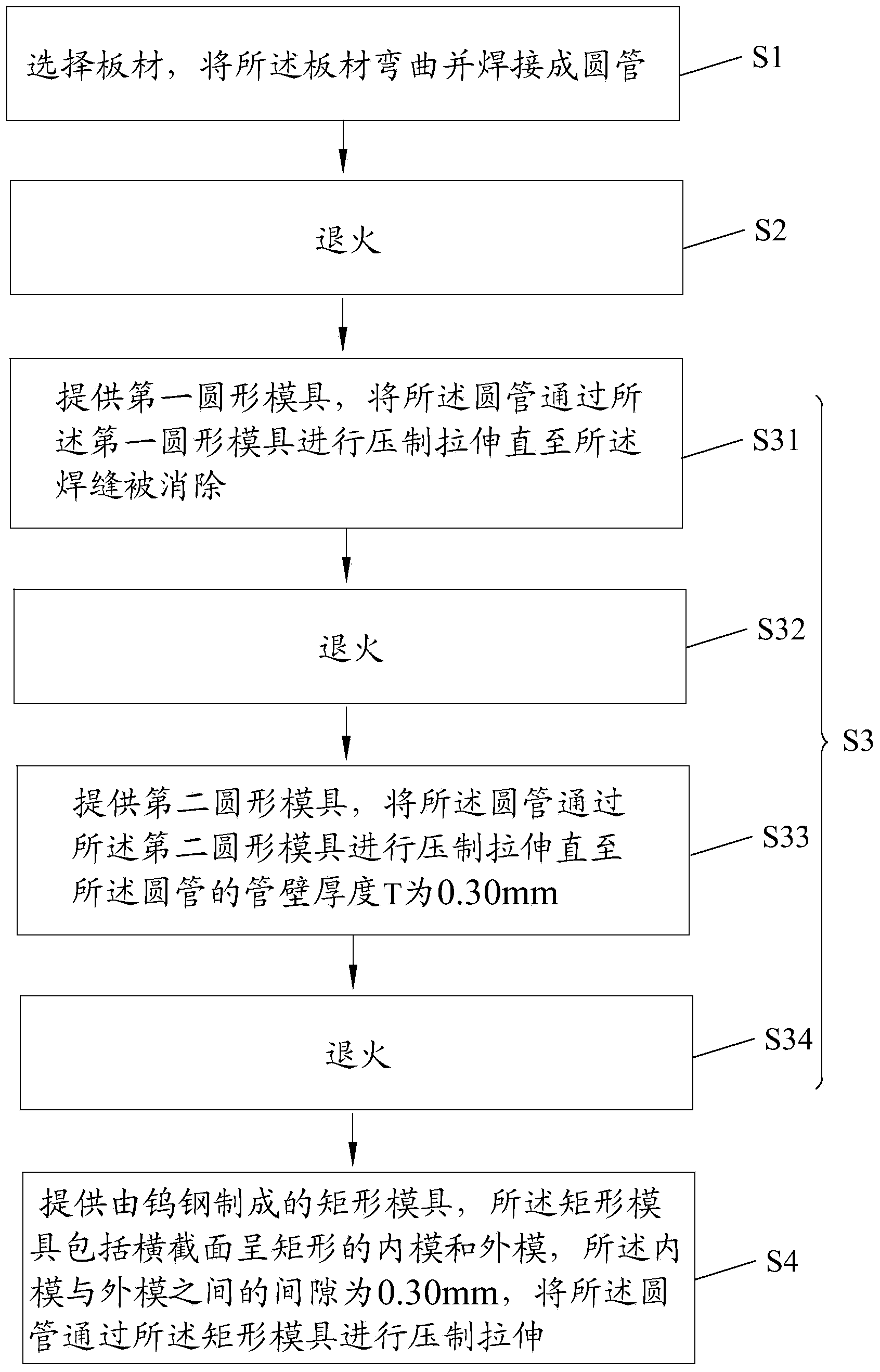

[0027] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

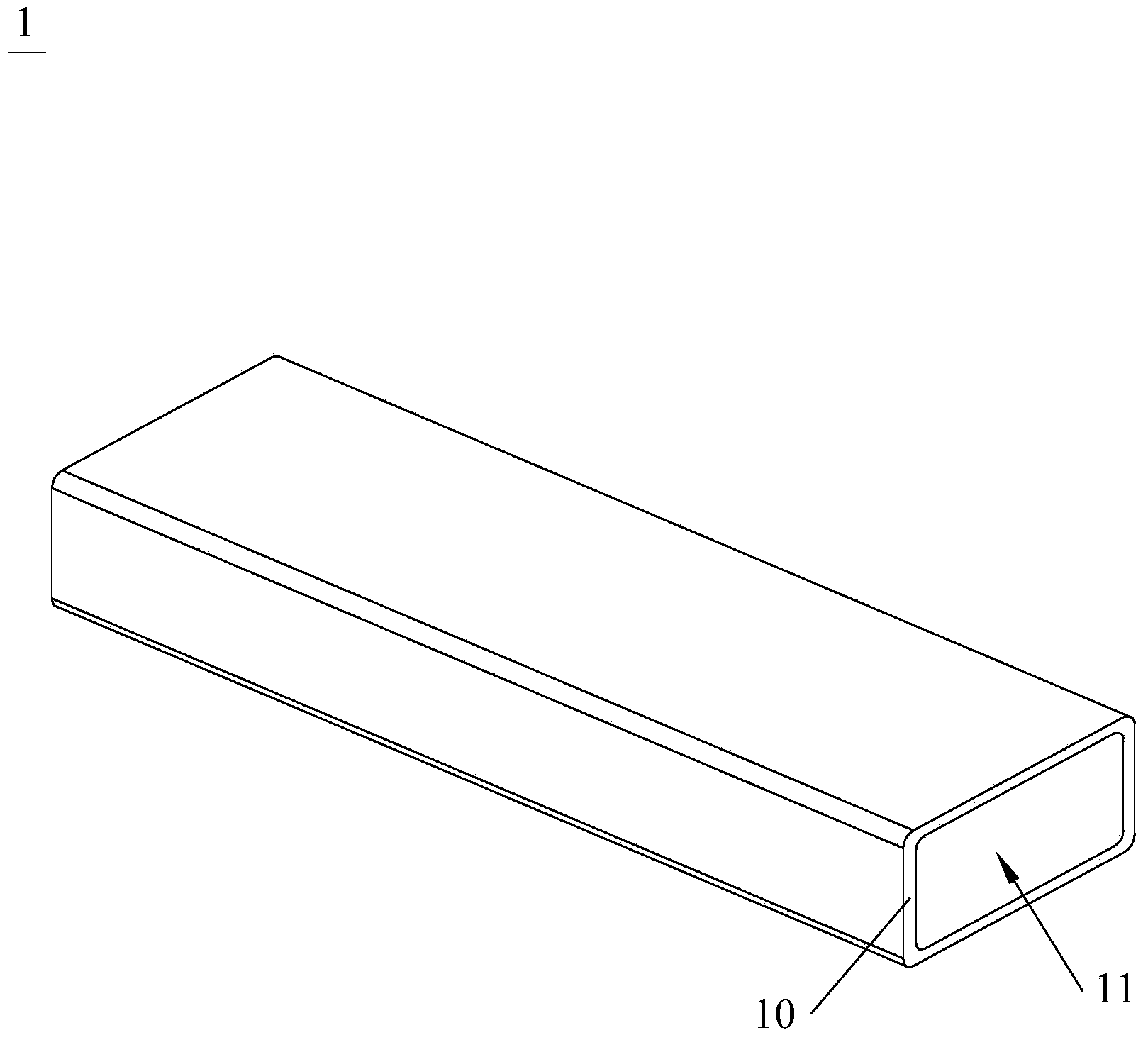

[0028] Such as figure 1 , figure 2 As shown, the present invention discloses a rectangular tube 1 which can form a seamless USB shell for a USB connector after cutting and related processing.

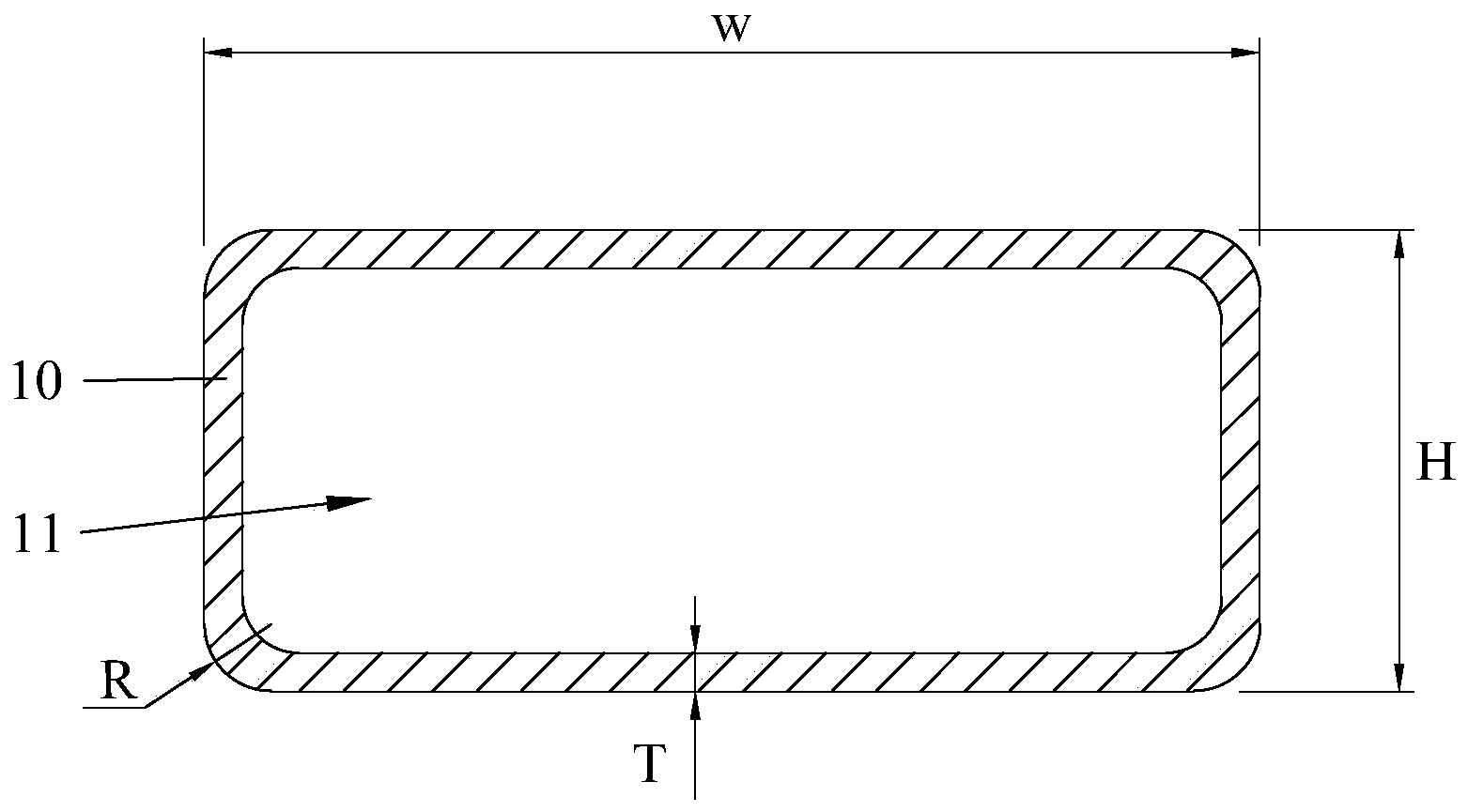

[0029] The rectangular tube 1 includes a tube wall 10 with a uniform thickness, and the tube wall 10 is closed to form an inner cavity 11 . The outer contour of the rectangular tube 1 and the cross section of the inner cavity 11 are rectangular. In detail, the cross section of the rectangular pipe 1 is a rectangular ring structure with a rectangular inner cavity 11 inside. The tube wall 10 of the rectangular tube 1 does not have any gaps that affect the performance of the seamless USB case.

[0030] The thickness T of the tube wall 10 of the rectangular tube 1 is 0.30-0.35mm, the width W of the rectangular tube 1 is 12.00±0.05mm, and the height H of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com