Air compressor residual heat recovery system for furniture production workshop

A waste heat recovery system and production workshop technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as atmospheric impact and energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

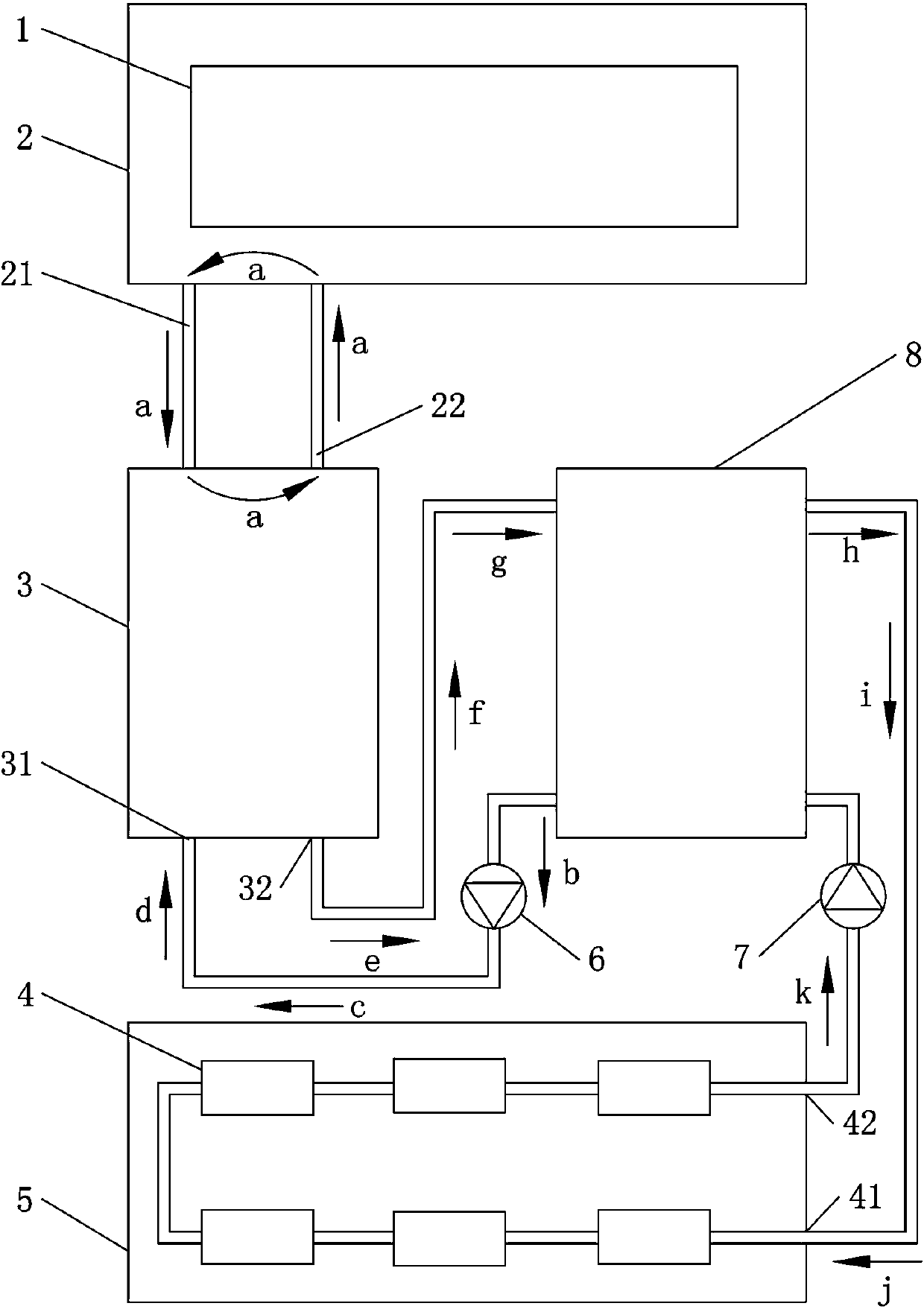

[0016] Embodiment one, such as figure 1 As shown, an air compressor waste heat recovery system for a furniture production workshop includes a drying room 5, an air compressor body 1 and an air compressor cooling device 2, and the air compressor cooling device 2 is arranged outside the air compressor body 1. The cooling device 2 of the air compressor is provided with a hot flow discharge pipe 21 and a cold flow inlet pipe 22. It is characterized in that it also includes a heat exchanger 3, a heat preservation water storage tank 8 and an evaporation pipe 4. The heat exchanger 3 is provided with two sets of mutual heat exchange pipes. Among them, one group of channels is connected to the hot flow discharge pipe 21 and the cold flow inlet pipe 22, and the other group of channels communicates with the heat preservation water storage tank 8 through the first water pump 6, and the evaporation pipe 4 is arranged in the drying room 5, And communicate with the heat preservation water st...

Embodiment 2

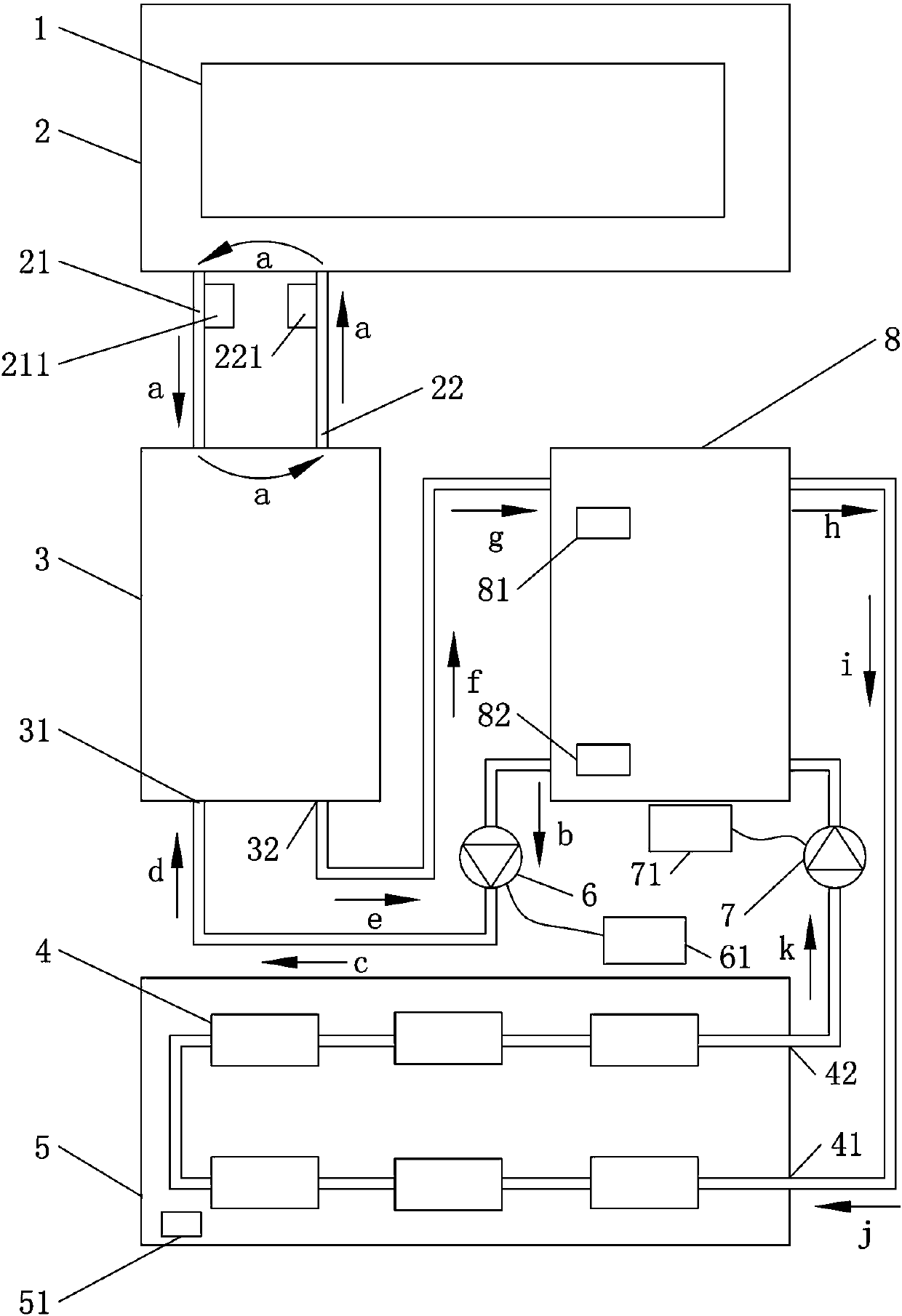

[0021] Embodiment two, such as figure 2 As shown, the air compressor waste heat recovery system used in furniture production workshops includes a control circuit, a first temperature sensor 211 is provided at the hot flow discharge pipe 21 of the air compressor cooling device 2, and a second temperature sensor 211 is provided at the cold flow inlet pipe 22. sensor 221. The first temperature sensor 211 and the second temperature sensor 221 are respectively electrically connected to the control circuit. The control circuit analyzes the temperature difference between the first temperature sensor 211 and the second temperature sensor 221, so as to realize the temperature drop of the air compressor body 1. In addition, by analyzing the temperature detected by the first temperature sensor 211, it is possible to know the temperature of the air compressor. The immediate temperature outside the main body 1, when the temperature detected by the first temperature sensor 211 is higher t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com