Wet spraying machine with sliding foldable arm

A technology of folding arm and wet spraying machine, which is used in wellbore lining, tunnel lining, underground chamber, etc., can solve the problems of harsh construction environment, inconvenient transportation, poor road passability, etc., so as to reduce the health hazards of construction workers and reduce Worker labor intensity, the effect of reducing springback and slump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

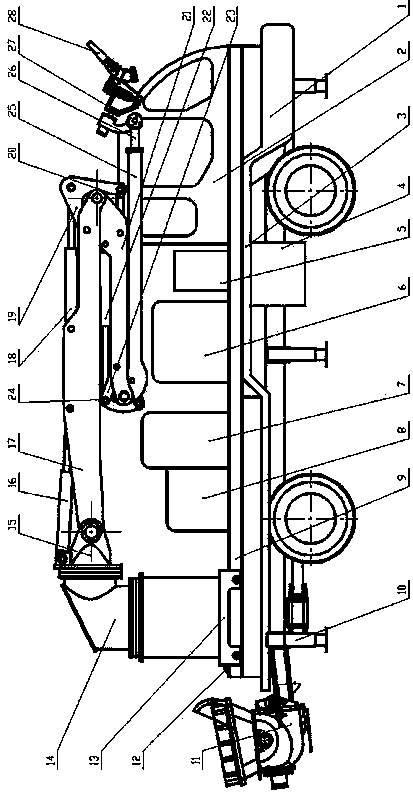

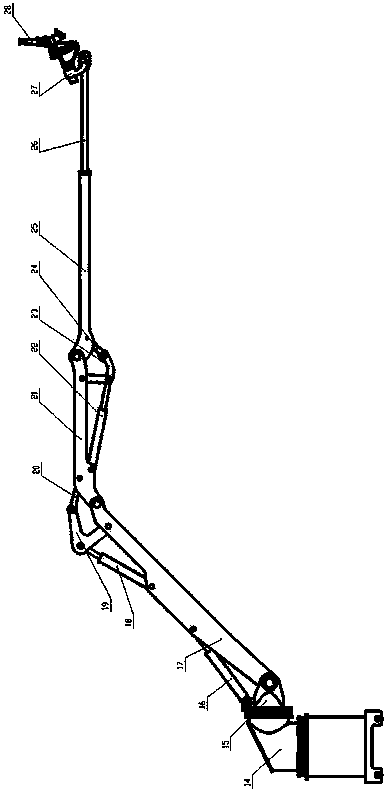

[0023] Below in conjunction with accompanying drawing, the present invention will be further described:

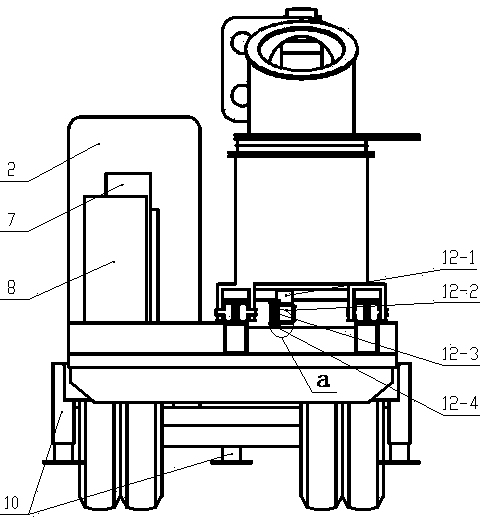

[0024] Such as figure 1 As shown, a sliding folding arm wet spraying machine includes a vehicle frame 3, a driver's cab 2 arranged on the vehicle frame 3 in a left-biased manner, a power system 4 is arranged below the vehicle frame 3, and An electric control system 5, an external additive system 6, a hydraulic system 7, an air pressure system 8, and a pumping system 11 connected to the vehicle frame 3 are set, and the construction machinery chassis 1 is arranged on the right vehicle frame 3 of the driver's cab 2. The mechanical chassis 1 is provided with a sliding and folding arm frame; the lower part of the sliding and folding arm frame is connected with a sliding base 13 with bolts, and a traveling mechanism 12 is arranged below the sliding base 13, and the traveling structure 12 is arranged on the guide rail 9, and the guide rail 9 is fixed on the vehicle frame 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com