Natural gas synergist and preparation method thereof

A synergist and natural gas technology, applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of easy carbon deposition, pollution of the working environment, high energy consumption, etc., and achieve the effect of reducing hazards and lowering the explosion limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The natural gas synergist of the present invention is according to following formula ratio (by mass percentage): 12.7% 2-methylpentane, 41.775% five-carbon cycloalkane, 10% butane, 13% 2-methylbutane Alkanes, 16% propane, 2.5% isoheptane, 3.5% cycloheptane, 0.5% tetraethyl lead, 0.025% pigment.

[0008] The natural gas synergist is prepared as follows: mix 2-methylpentane, five-carbon cycloalkane, butane, 2-methylbutane, propane, isoheptane and cycloheptane according to the above ratio and stir for 2 hours , add tetraethyl lead and pigment, properly seal for 24 hours, and control the temperature at about 30°C to obtain the finished product;

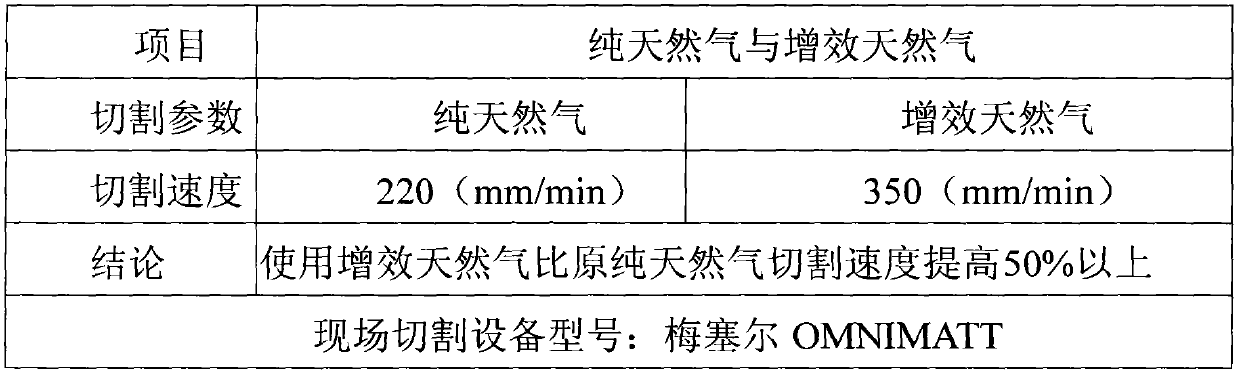

[0009] The explosive limit of industrial gas mixed with natural gas is 2.3%-10.5%, which is only 1 / 8 of that of acetylene (the explosive limit of acetylene is 2.5%-80%). The anti-shock and explosion-proof performance is safer than that of acetylene, and it is not easy to temper during use. , It cannot be ignited unless it is an op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com