Modified bitumen, modification method and application of high temperature bitumen for direct coal liquefaction

A technology for direct liquefaction of coal and high-temperature pitch, which is applied in the direction of chemically processing tar pitch/petroleum pitch/natural pitch, etc., to achieve the effects of low softening point, easy to scale up production, and conventional equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

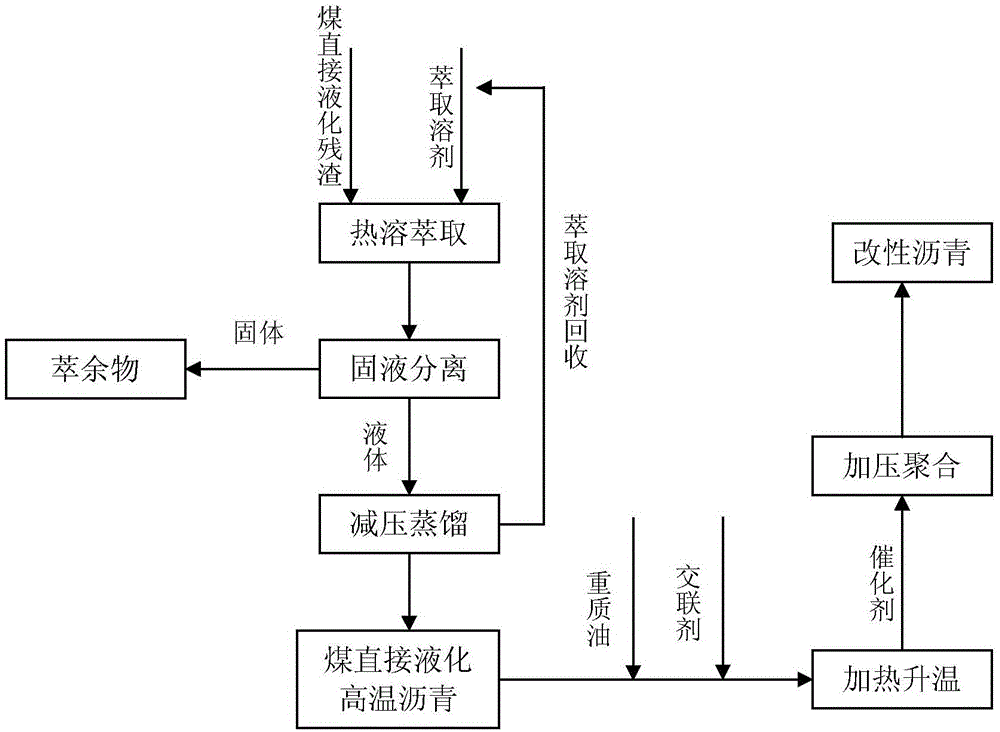

Method used

Image

Examples

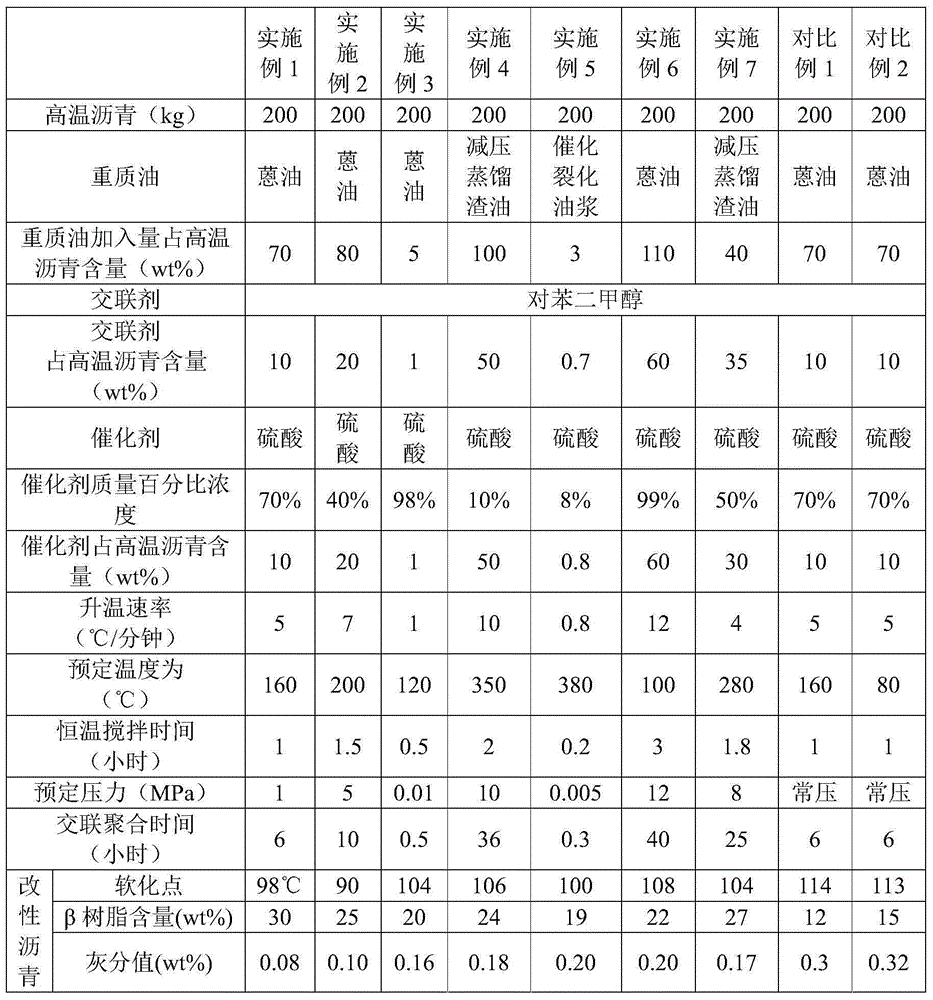

Embodiment 1

[0039] The coal direct liquefaction residue was processed by thermal extraction, solid-liquid separation, and vacuum distillation to obtain direct coal liquefaction high-temperature pitch with an ash content of 0.45wt%, a β resin content of 7wt%, and a softening point of 130°C.

[0040] 1) Add 200Kg coal direct liquefaction high-temperature asphalt, anthracene oil and cross-linking agent tere-phenylenedimethanol into a stirring tank, stir and mix to obtain the first mixture. The added anthracene oil is 70wt% of the direct coal liquefaction high temperature asphalt, and the terephthalmic alcohol is 10wt% of the coal direct liquefaction high temperature asphalt. The first mixture was placed under a nitrogen atmosphere, heated to 160° C. at a heating rate of 5° C. / min, and stirred at constant temperature for 1 hour to obtain a second mixture.

[0041] 2) Add sulfuric acid (concentration: 70wt%) accounting for 10wt% of direct coal liquefaction high-temperature asphalt to the secon...

Embodiment 8

[0049] Firstly, the direct coal liquefaction residue is used for thermal extraction, solid-liquid separation, and vacuum distillation to obtain direct coal liquefaction high-temperature pitch. The ash content is 0.35wt%, the β resin content is 5wt%, and the softening point is 115°C.

[0050] 1) Add 200Kg of the above-mentioned coal liquefaction high-temperature pitch, 100Kg of anthracene oil and 2Kg of terephthalmic alcohol into a stirring tank, stir and mix to obtain the first mixture. Under the protection of a nitrogen atmosphere, the temperature was raised to 200° C. at a heating rate of 1° C. / min and stirred at a constant temperature to obtain a second mixture.

[0051] 2) Add 2Kg of sulfuric acid with a concentration of 98wt% to the second mixture at 200°C, pressurize to 10Mpa and react for 36h, stop heating, and take out to obtain the coal direct liquefaction modified pitch. The measured softening point of coal direct liquefaction modified asphalt is 117°C, the content o...

Embodiment 9

[0053] The direct coal liquefaction high temperature bitumen is obtained by hot solution extraction, solid-liquid separation and vacuum distillation from the coal direct liquefaction residue, the ash content is 0.01wt%, the beta resin content is 15wt%, and the softening point is 160°C.

[0054] 1) Add 200Kg of the above-mentioned coal liquefaction high-temperature bitumen, 200Kg of vacuum residue and 100Kg of terephthalmic dimethanol into the stirring tank to obtain the first mixture. The first mixture was placed under a nitrogen atmosphere, and the temperature was raised to 350° C. at a heating rate of 10° C. / min for constant temperature stirring to obtain a second mixture.

[0055] 2) Then add 200Kg of sulfuric acid with a concentration of 40wt% to the second mixture, then pressurize to 5Mpa and react for 10h, stop heating, and take out the obtained coal liquefaction modified pitch. The measured softening point of the product is 112°C, the beta resin content is 27 wt%, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com