Method and equipment for continuously extracting p-benzoquinone from aniline-oxidized oxidized material

A technology for p-benzoquinone and oxidizing materials, applied in chemical instruments and methods, solvent extraction, separation methods, etc., can solve the problems of reduced yield, high equipment requirements, and easy decomposition of benzoquinone, etc., with simple methods and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Example 1. Take 500ml of oxidizing material with a benzoquinone content of 5%, put it into a 1000ml separatory funnel, add 250ml of methyl isobutyl ketone, mix evenly for 3 minutes, pour the mixed solution into a filter and filter , to separate the manganese mud from the liquid. Put the filtrate into the separatory funnel and let it stand for 5 minutes, release the lower layer as benzoquinone aqueous solution, repeat the extraction 8 times, add the extraction dose according to 200ml, 150ml, 150ml, 100ml, 100ml, and ensure that the concentration of the extract phase in the first extraction tower reaches 5 %, extracted until the benzoquinone content (mass fraction) in the aqueous solution is lower than 0.03%. The upper layer is p-benzoquinone solution, collected for use. The manganese mud is stirred and washed with 30ml~50ml of solvent each time, and the filtered liquid is used as the extractant of the above filtrate.

[0012] Product yield: p-benzoquinone yield ≥ 98%. ...

Embodiment 2

[0013] Embodiment 2, get benzoquinone content and be 3% oxidation material 1000ml, insert in the 2000ml separatory funnel, then add the butyl acetate of 800ml, mix evenly, time 3 minutes, the mixed solution is poured in filter and filtered, makes manganese The mud is separated from the liquid. Put the filtrate into the separatory funnel and let it stand for 5 minutes, release the lower layer as benzoquinone aqueous solution, repeat the extraction 6 times, add the extraction dose according to 600ml, 400ml, 400ml, 200ml, 200ml, and ensure that the concentration of the extract phase in the first extraction tower reaches 18 %, extracted until the benzoquinone content (mass fraction) in the aqueous solution is lower than 0.03%. The upper layer is p-benzoquinone solution, collected for use. The manganese mud is stirred and washed with 30ml~50ml of solvent each time, and the filtered liquid is used as the extractant of the above filtrate.

[0014] Product yield: p-benzoquinone yiel...

Embodiment 3

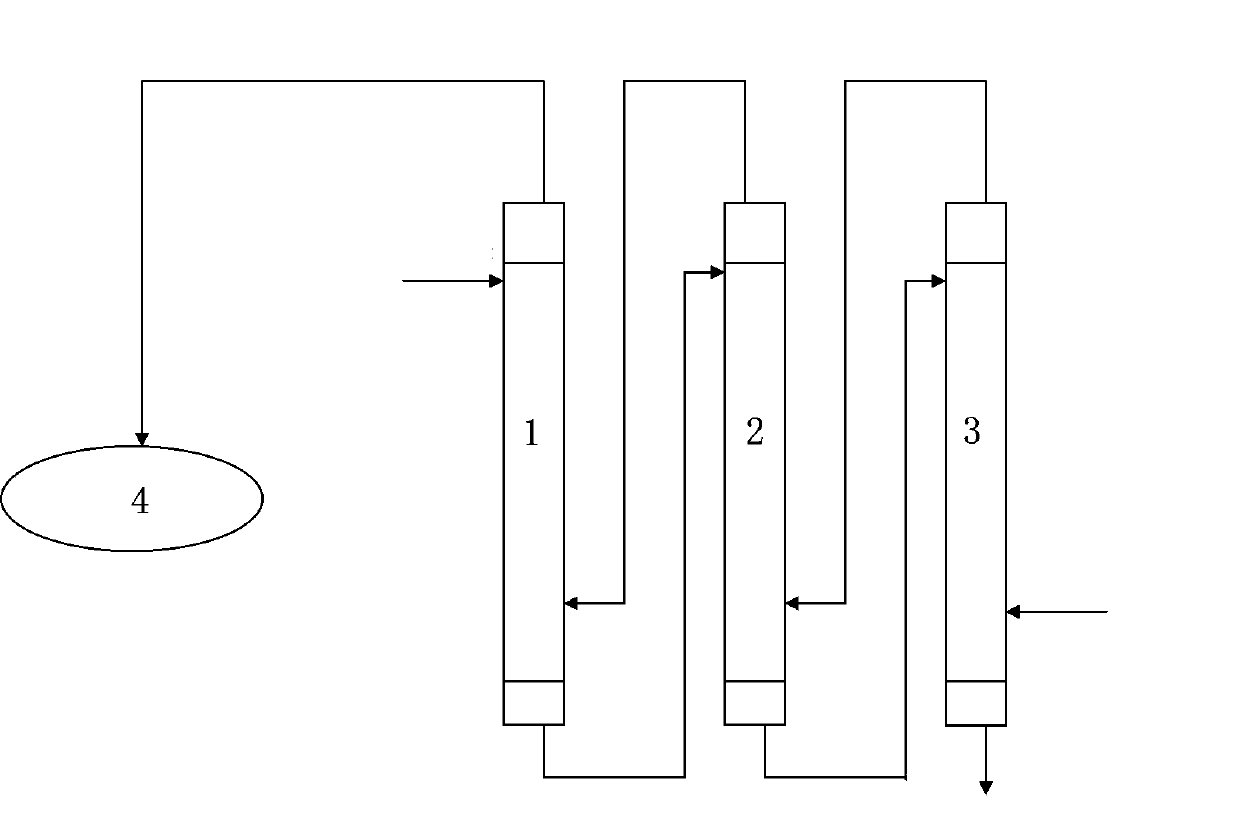

[0016] Add 650L of oxidizing material water suspension with a p-benzoquinone content of 4% (mass percentage) into the high-speed continuous mixer, add 280L of sec-butyl acetate, stir and mix for 15 minutes, and the mixed liquid enters the solid-liquid separator , to separate the solid manganese mud from the liquid. The liquid is injected from the upper part of the extraction tower 1, and the extraction phase and the raffinate phase are fully separated as the liquid falls. The extraction phase is poured into countercurrent contact at 5 places, and the p-benzoquinone is extracted from the raffinate phase to obtain a new extract phase. The phase falls and contacts with the extraction phase injected from the bottom 1 / 5 of the extraction tower 3 in countercurrent, and the p-benzoquinone is extracted from the raffinate phase to obtain a new extraction phase. The extraction phase rises and enters the extraction tower 1 after coming out from the top of the extraction tower 2 The lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com