Pill counting and filling machine

A filling machine and pill technology, applied in the directions of packaging, transportation and packaging, and the type of packaging items, can solve the problems of large space, high cost, large volume, etc., and achieve flexible placement of equipment, accurate counting, and overall Small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

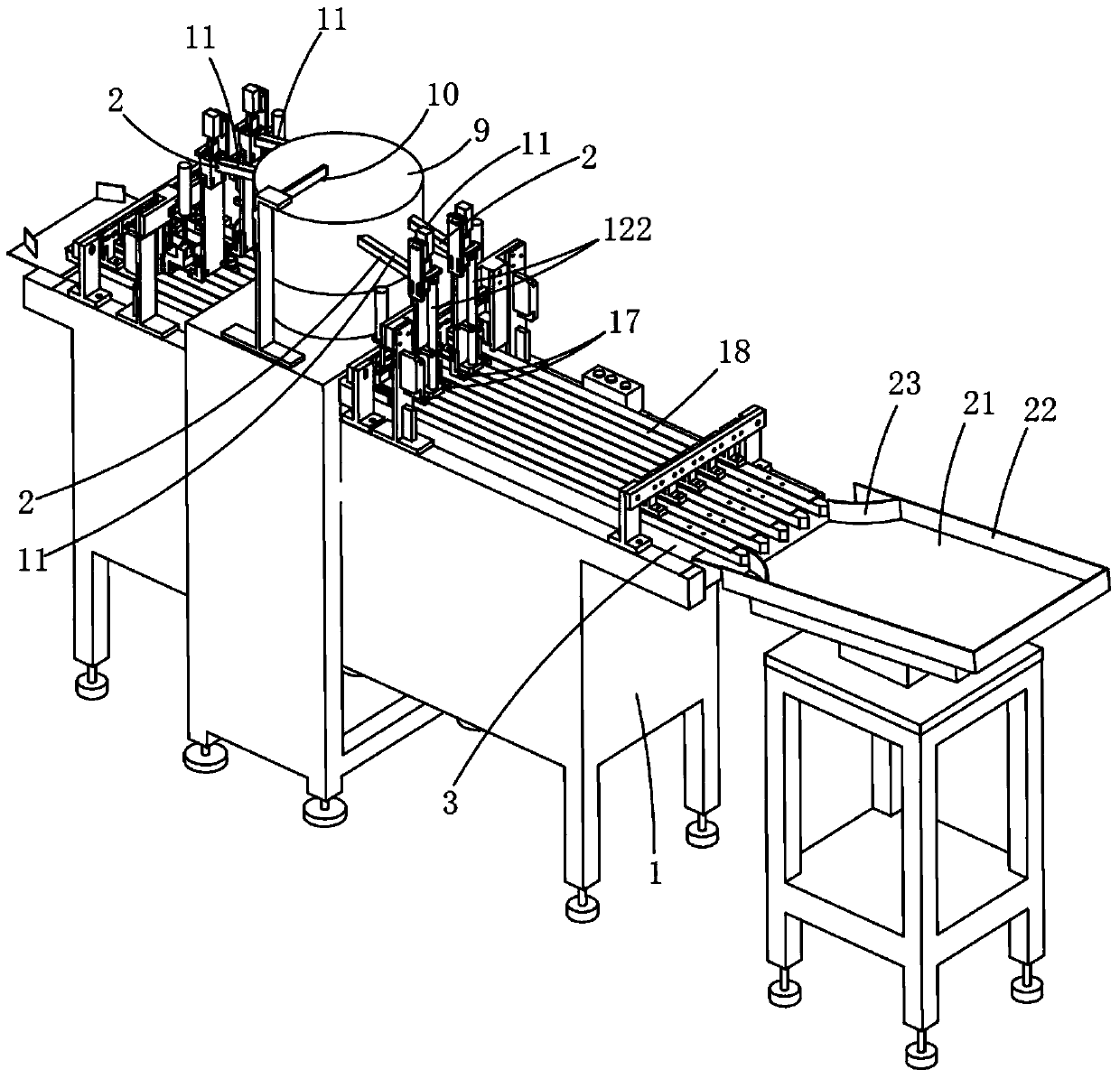

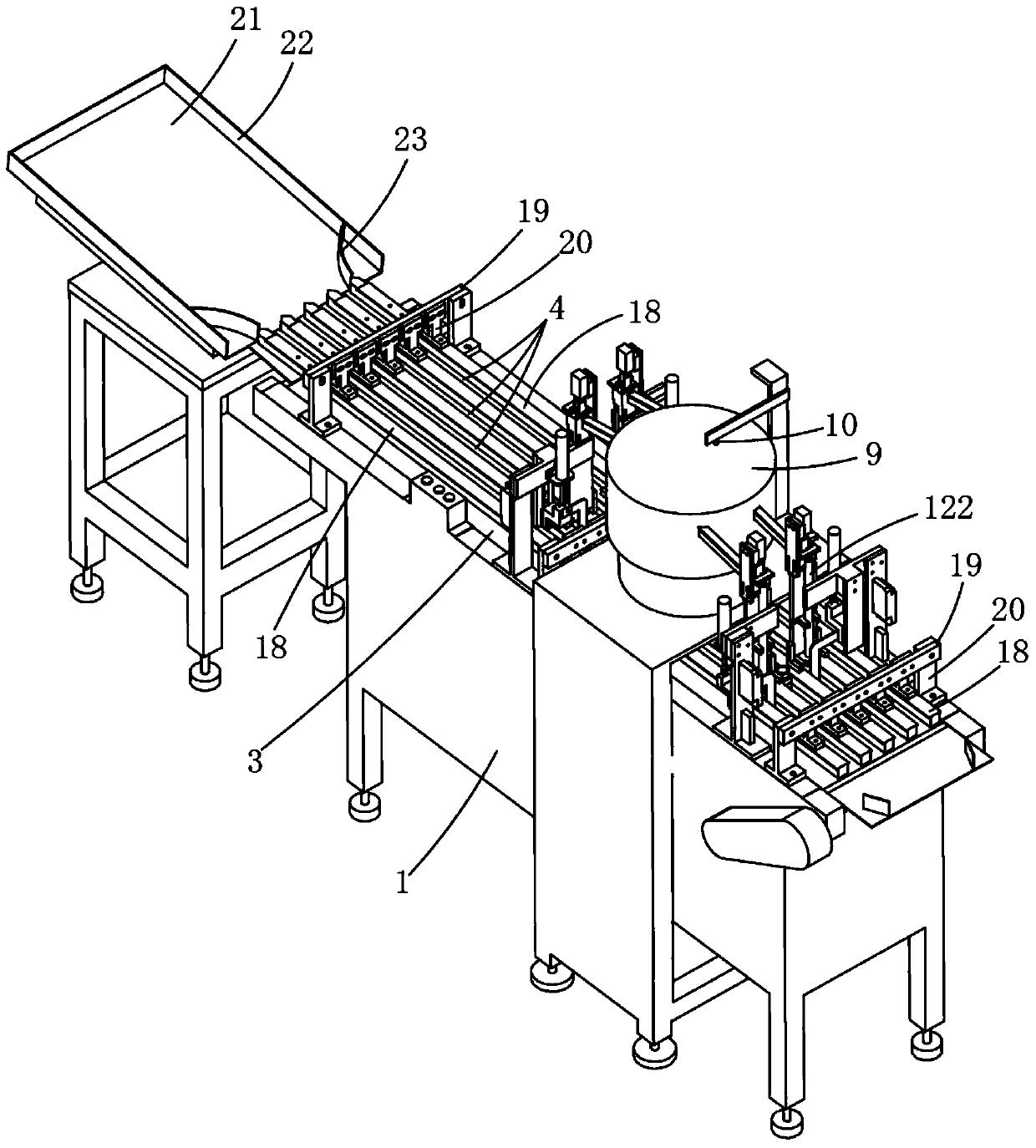

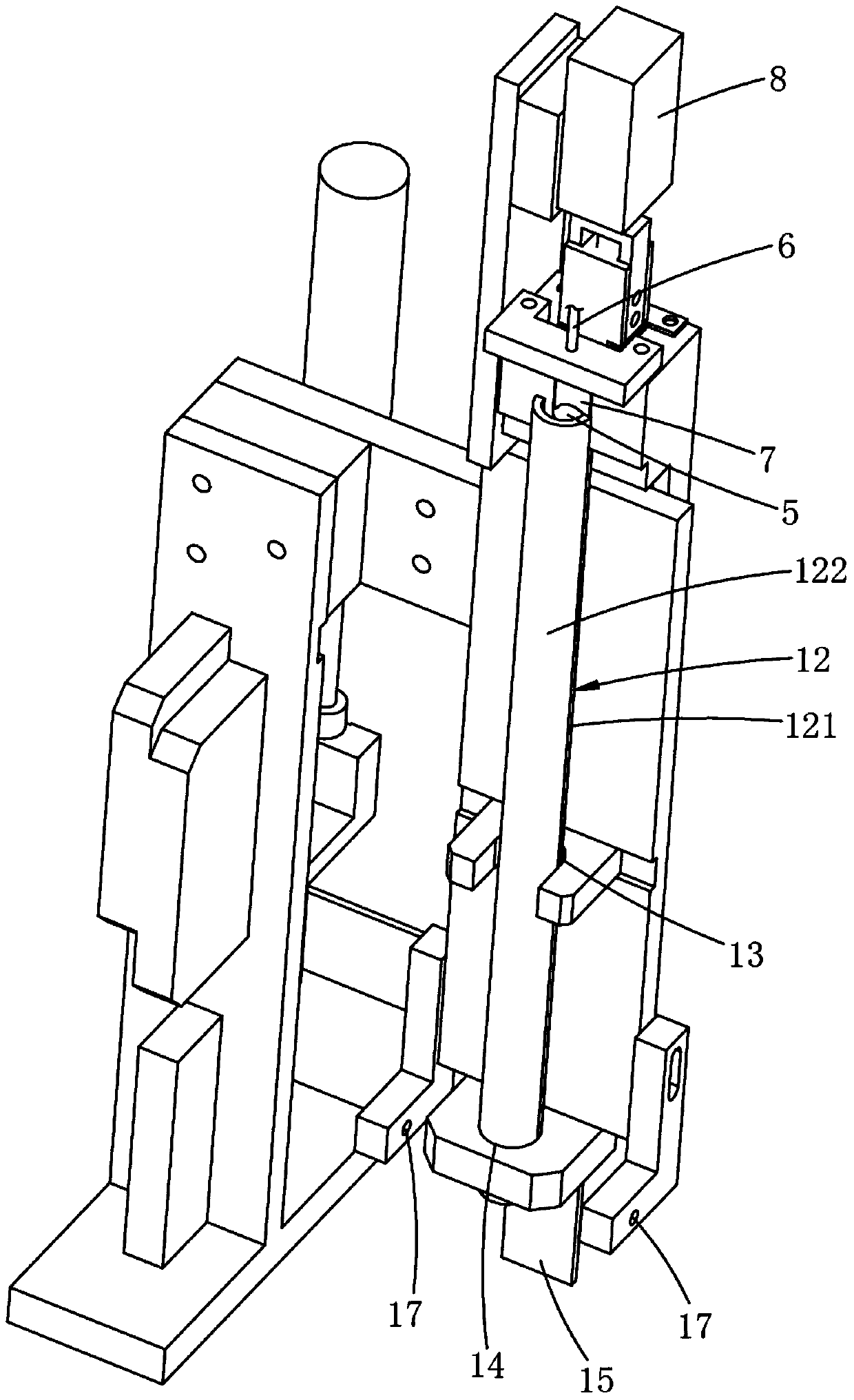

[0026] Examples, see Figure 1 to Figure 7 As shown, a pill counting and filling machine includes a frame 1, a pill output mechanism and a pill counting and quantitative output device are arranged above the frame 1, and a vibrating plate 9 is used for the pill output mechanism, and a pill sensor A device 10 is used to sense whether there are pills in the vibration plate 9, and the pill sensor 10 is an infrared sensor, a microwave sensor or a laser sensor.

[0027] A first pill conveying pipe 2 is connected between the pill output mechanism and the pill counting and quantitative output device, a conveyor belt 3 is fixed above the frame 1, and a limiting channel 4 is arranged above the conveyor belt 3 to limit independent passage of bottles and cans, wherein, Limiting channel 4 comprises some limiting plates 18 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com