Turning and lifting integrated equipment used for recycling and disassembling scraped car

A scrapped car, turning and lifting technology, which is applied in the direction of vehicle scrapping and recycling, recycling technology, motor vehicles, etc., can solve the problems of less reporting of devices with integrated transportation, turning, and lifting functions, so as to facilitate dismantling operations and improve safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

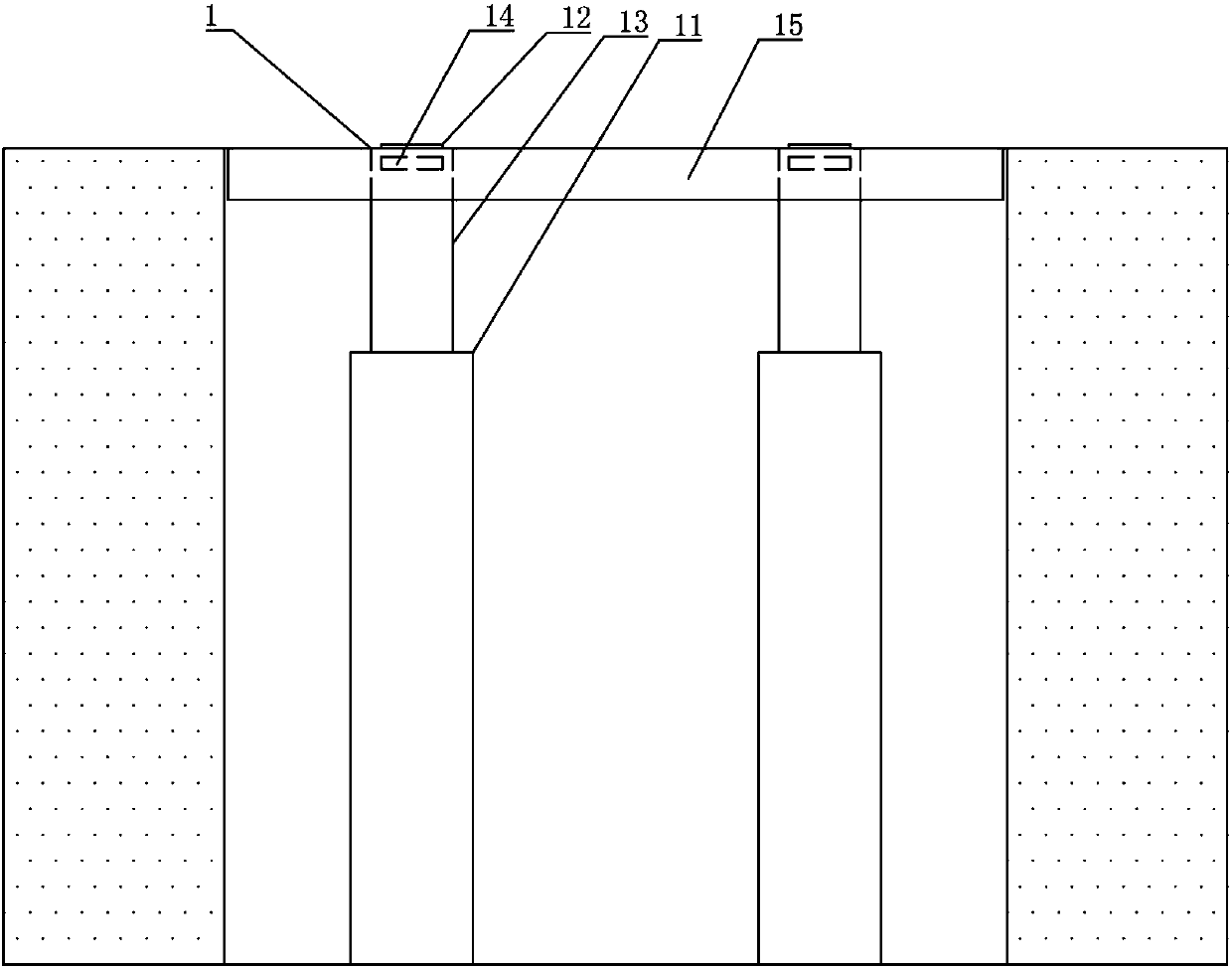

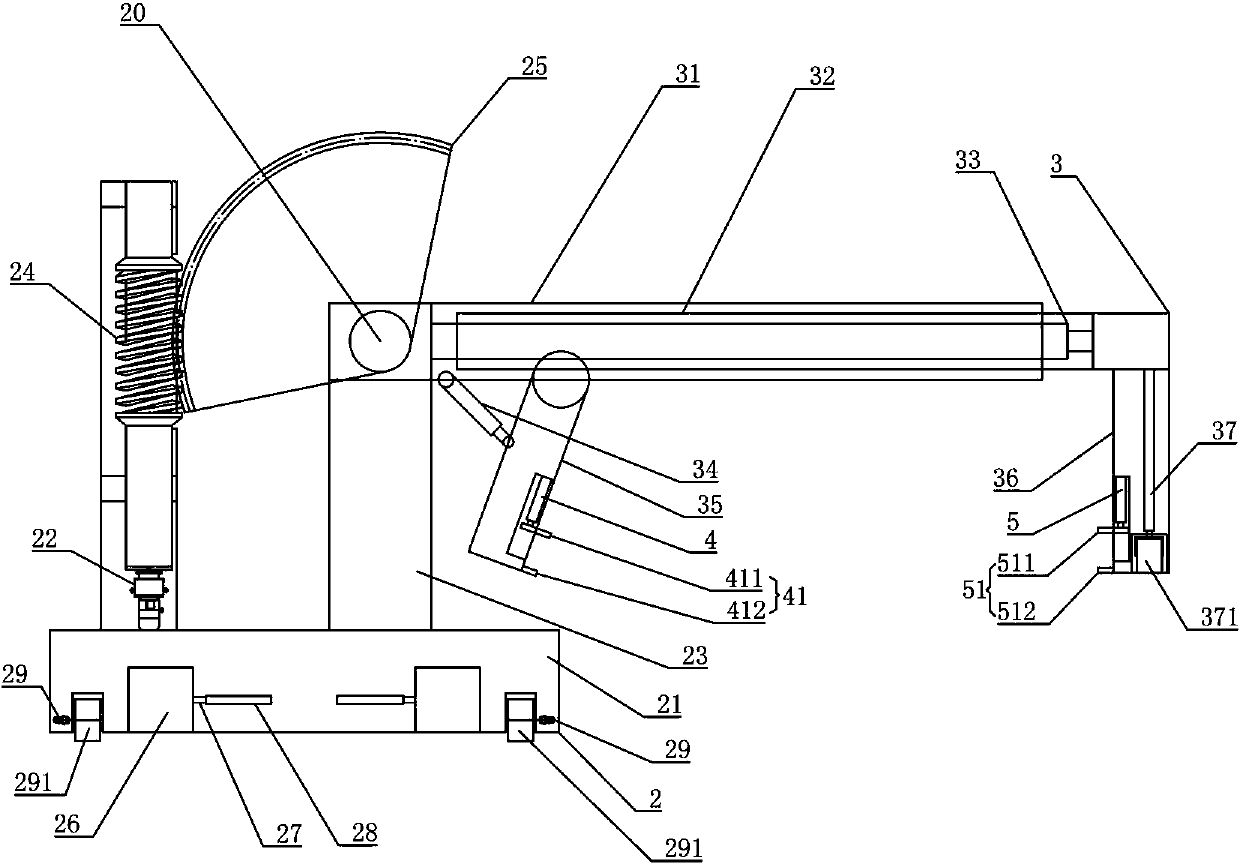

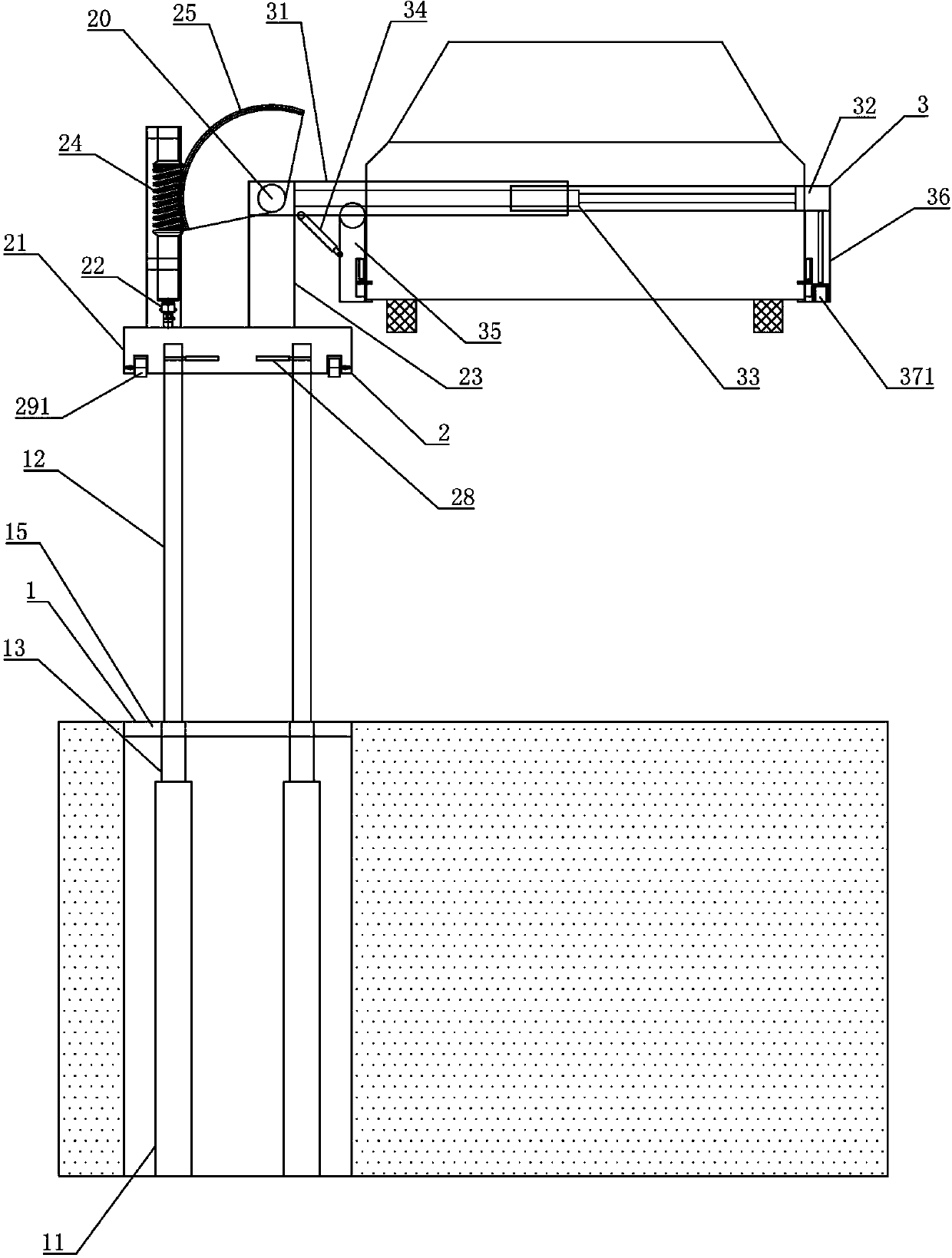

[0025] Such as Figure 1~Figure 4 As shown, a flipping and lifting integrated equipment for recycling and dismantling scrapped vehicles includes a ground lifting platform 1, and the ground lifting platform 1 includes a telescopic hydraulic cylinder 11, and the telescopic hydraulic cylinder 11 includes two or more stages of steel The cylinder, in this embodiment, is preferably two-stage, that is, it includes a primary steel cylinder 12 and a secondary steel cylinder 13 , and the primary steel cylinder 12 is movably socketed in the secondary steel cylinder 13 . The top of the primary steel cylinder 12 is horizontally provided with a rod hole 14 for fixing the support base 21 , and the secondary steel cylinder 13 is fixedly connected with a load-bearing platform 15 for receiving the turning device 2 . The ground lifting platform 1 is connected with an overturning device 2, and the overturning device 2 includes a support base 21. The bottom of the support base 21 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com