Moulding process of carbon fiber composite heavy-wall pipe

A composite material and molding process technology, used in tubular articles, other household appliances, household appliances, etc., can solve the problems of easy generation of voids, low fiber volume content, poor operating environment, etc., to expand the scope of application, low volatile content , the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A forming process of a carbon fiber thick-walled pipe, comprising the following steps:

[0030] a. Prepare unidirectional carbon fiber prepreg, and cut the prepreg according to the length and thickness of the pipe;

[0031] b. Laying up: laying up the above-cut blanks, according to actual needs, using prepregs with different surface densities to adjust the distribution ratio of fibers in the directions of 0° and 90° through the laying process, so that the present invention can The thick-walled tube fibers produced by the provided molding process have a 0°, 90° orthogonal lay-up structure;

[0032] c. Rolling tube: iron the stacked blank on the mandrel coated with release agent, and then use a tube rolling machine to roll the tube. The temperature of the tube rolling platform is 15~40°C, and the pressure of the tube rolling is 0.2~0.6MPa , according to the length of the blank and the effective coiling stroke of the equipment, the same tube can be rolled repeatedly for s...

Embodiment 2

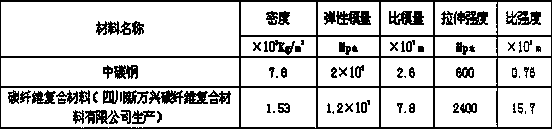

[0040]The carbon fiber composite thick-walled pipe prepared in Example 1 was used as the carrier of the self-floating logging tool. The prepared carbon fiber composite thick-walled pipe is used as the carrier of the logging tool (this is only to illustrate that the thick-walled pipe can be used as the carrier of the logging tool, no specific description is required), sent into the well, and the relevant data. The carbon fiber composite material thick-walled pipe provided in Example 1 is light in weight and can float quickly in the well, which can improve the timeliness and accuracy of well logging data. The present invention uses the thick-walled pipe produced by T700 grade carbon fiber epoxy resin prepreg, which has an inner diameter of φ37mm, an outer diameter of φ49mm, a length of 1200mm, and an external pressure resistance of more than 80MPa. The carbon fiber composite material thick-walled pipe produced by the molding process provided by the present invention When applie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com