Immobilized graphite carbon nitride functional-bamboo and preparation method thereof

A graphite-phase carbon nitride and functional technology, applied in wood treatment, manufacturing tools, wood processing appliances, etc., can solve problems such as infection by moths and molds, poisonous chemicals, products and environmental pollution, etc., to improve mildew resistance, Easy to remove, extend the range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

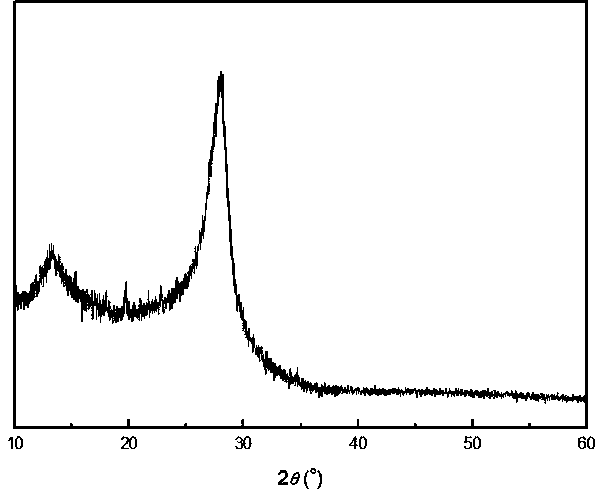

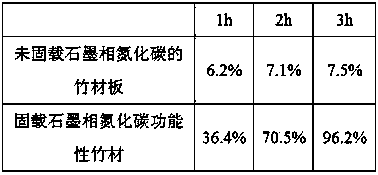

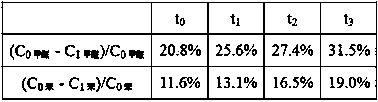

Method used

Image

Examples

Embodiment 1

[0012] (1) Remove the bamboo green and bamboo yellow from the bamboo, and dry it in an oven at 103°C for 24 hours.

[0013] (2) Take 5g of trichloroazine (C 3 N 3 C1 3 ) and 3g of ammonium chloride (NH 4 C1) put into the autoclave, then add 200 ml of benzene, after stirring for 30min, place the bamboo of step 1) in the autoclave, feed nitrogen into the autoclave to fully drive away the air in the autoclave system, and Apply a pressure of 30MPa to the reactor, then raise the temperature in the reactor to 300°C at a rate of 1°C / min, and react at constant temperature and pressure for 3 hours. After naturally cooling to room temperature, take out the bamboo and The product was washed with hydrochloric acid and acetone, and then the bamboo was repeatedly washed with distilled water until the cleaning solution was neutral, and then dried in an oven at 103°C to obtain a functional bamboo with graphite phase carbon nitride.

Embodiment 2

[0015] (1) Remove the bamboo green and bamboo yellow from the bamboo, and dry it in an oven at 103°C for 24 hours.

[0016] (2) Take 8 g of trichloroazine (C 3 N 3 C1 3 ) and 4g of ammonium chloride (NH 4 C1) put into the autoclave, then add the benzene of 300 ml, after stirring for 30min, place the bamboo of step 1) in the autoclave, feed nitrogen into the autoclave to fully drive away the air in the autoclave system, and Apply a pressure of 35MPa to the reactor, then raise the temperature in the reactor to 250°C at a rate of 2°C / min, and react at constant temperature and pressure for 2 hours. After cooling down to room temperature naturally, take out the bamboo, and The product was washed with hydrochloric acid and acetone, and then the bamboo was repeatedly washed with distilled water until the cleaning solution was neutral, and then dried in an oven at 103°C to obtain a functional bamboo with graphite phase carbon nitride.

Embodiment 3

[0018] (1) Remove the bamboo green and bamboo yellow from the bamboo, and dry it in an oven at 103°C for 24 hours.

[0019] (2) Take 10g of trichlorozine (C 3 N 3 C1 3 ) and 3.5g of ammonium chloride (NH 4 C1) put into the autoclave, then add the benzene of 500 ml, after stirring for 30min, place the bamboo of step 1) in the autoclave, feed nitrogen into the autoclave to fully drive away the air in the autoclave system, and Apply a pressure of 40MPa to the reactor, then raise the temperature in the reactor to 280°C at a rate of 1.5°C / min, and react at constant temperature and pressure for 2.5 hours. After naturally cooling to room temperature, take out the bamboo and Wash the product with hydrochloric acid and acetone in sequence, and then wash the bamboo repeatedly with distilled water until the cleaning solution is neutral, then place it in an oven and dry it at 103°C to obtain a functional bamboo with graphite phase carbon nitride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com