Machine tool multiple motion shaft parallelism detecting device and method

A detection device and motion axis technology, applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problems of cumbersome measurement steps, errors, and difficult digital processing, etc., to achieve real-time monitoring of parallelism, easy The process of building and parallelism adjustment is simple and feasible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

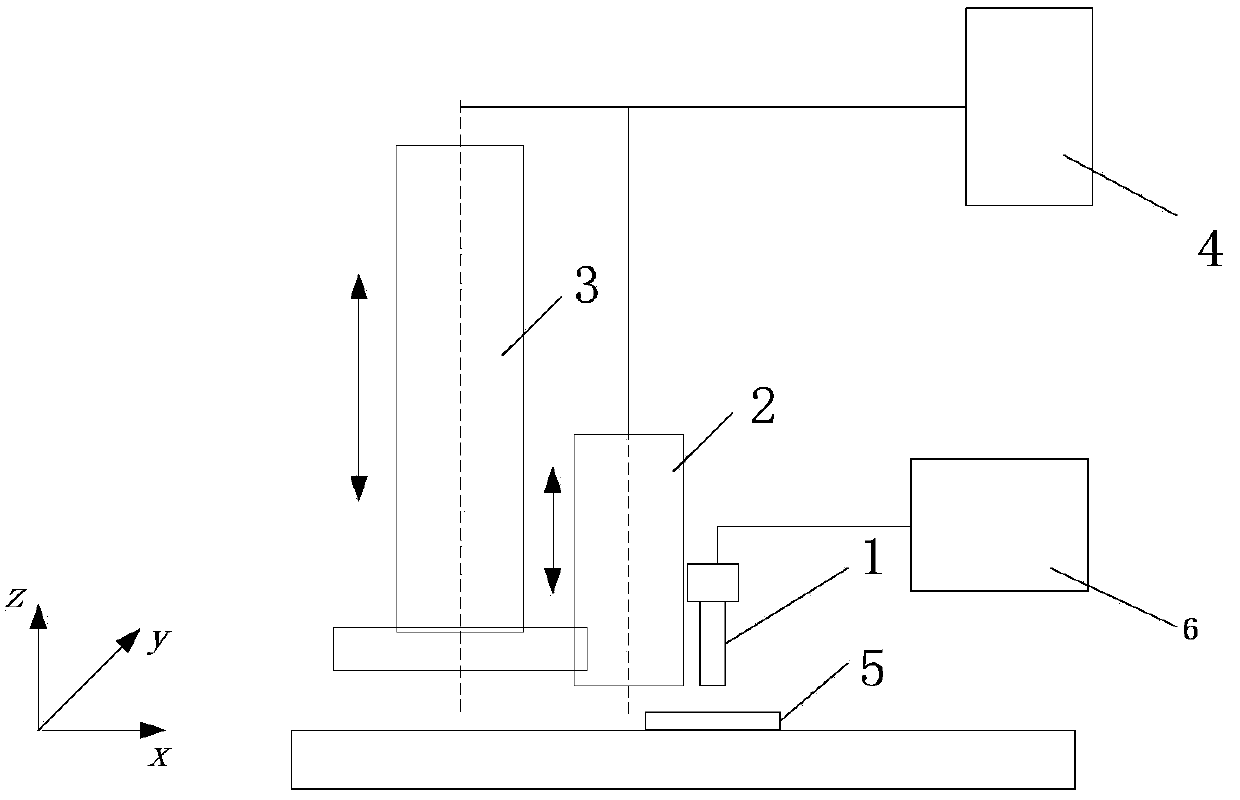

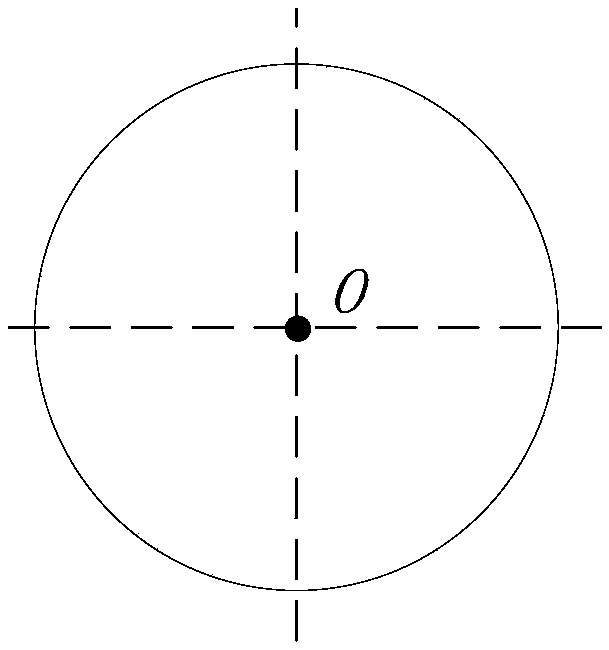

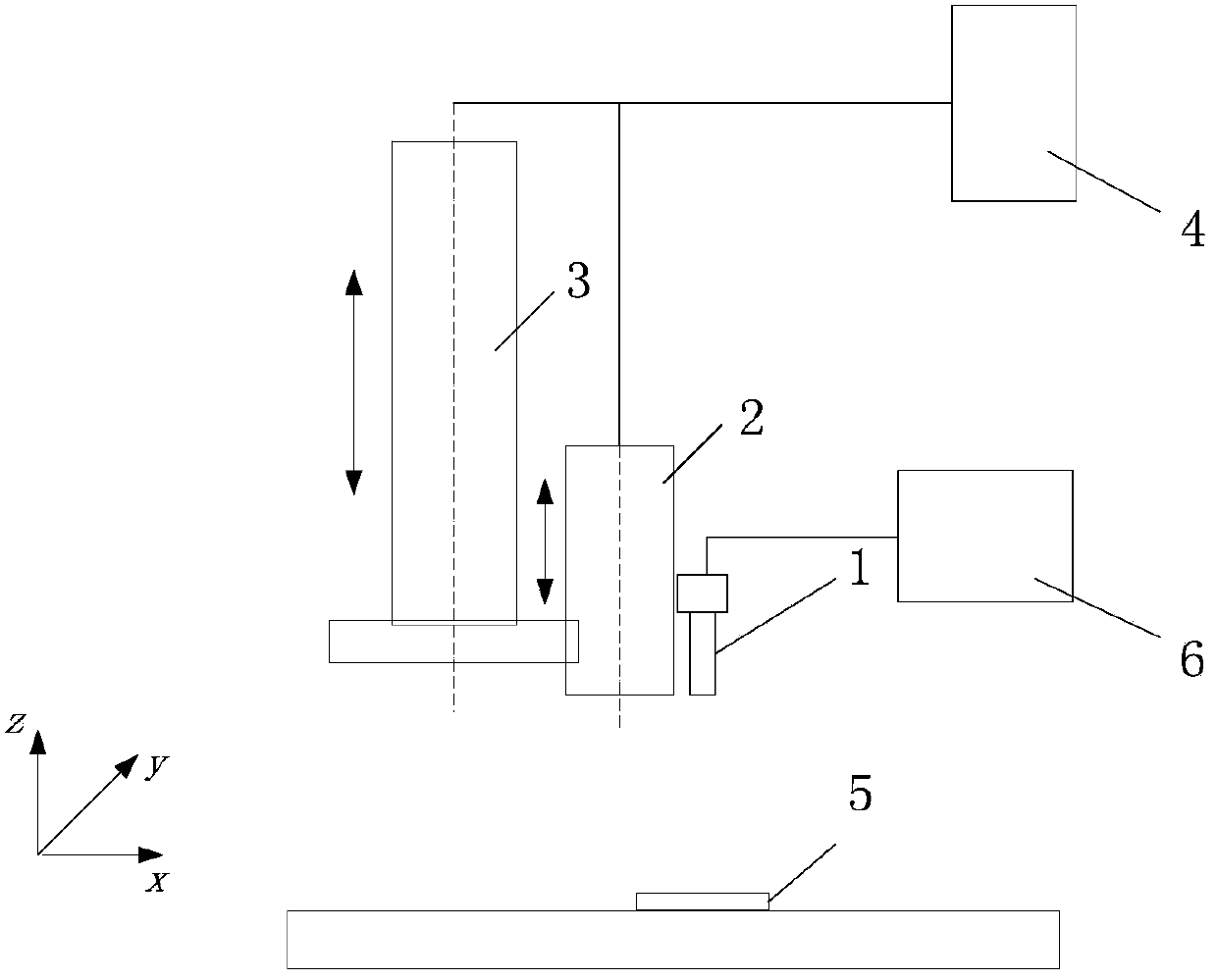

[0030] The invention realizes multi-motion axis parallelism detection by controlling the combined complementary motion of two or more parallel motion axes of the machine tool, and utilizing the CCD to detect the offset of the observation point on the calibration plate. The basic idea is to fix the CCD measuring device on the motion axis to be detected, and control the motion axis to be detected to move to the upper limit. The main motion axis drives the motion axis to be detected to move downward so that the observation point P on the calibration plate is clearly displayed on the measurement display system. Move the calibration plate horizontally so that the observation point P coincides with the central reference point O on the measurement display system. The main axis of motion moves upward by a distance H, and the axis to be detected moves downward by a distance H. At this time, the observation point P on the calibration plate is displayed at point O' on the measurement dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com