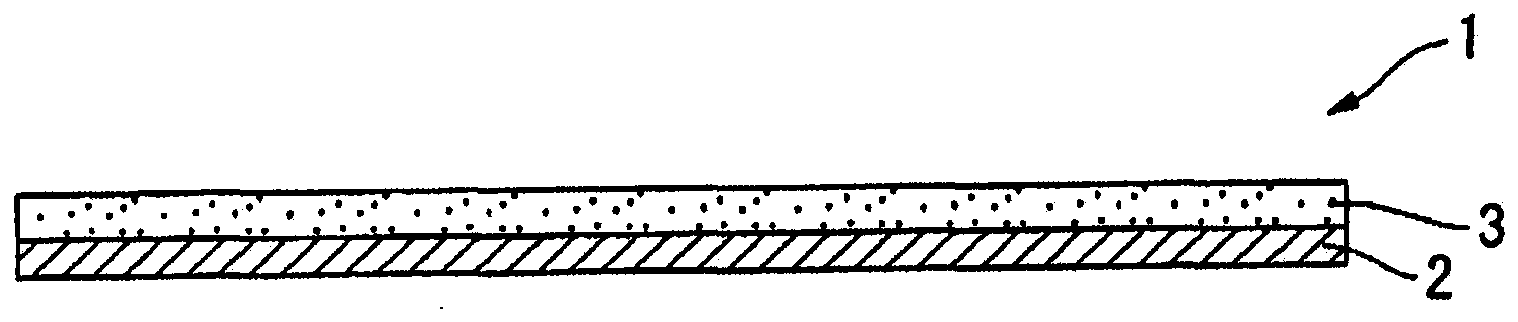

Dicing sheet substrate film and dicing sheet

A substrate film, cutting sheet technology, applied in film/sheet adhesive, transportation and packaging, non-polymer adhesive additives, etc., can solve the problem of yield drop, damage to package, poor device operation, etc. problem, to achieve the effect of easy production and reduction of cutting chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0119] (1) Production of substrate film

[0120] The tensile modulus at 23° C. of a cycloolefin copolymer (manufactured by Polyplastics Co., Ltd., product name TOPAS (registered trademark) 8007) which is a thermoplastic resin containing an aliphatic ring-containing resin (a1) (based on the test example described later) The results obtained in 1, the same below): 2.0 GPa, the fluidization temperature (based on the results obtained in Test Example 2 described later, the same below): 142° C.) 5.0 parts by mass, which is as low as the non-cyclic olefin resin (a2) Density polyethylene (manufactured by Sumitomo Chemical Co., Ltd., product name Sumikasen (registered trademark) L705, tensile modulus at 23°C: 140 MPa) 95.0 parts by mass, using a twin-screw kneader (manufactured by Toyo Seiki Seisakusho Co., Ltd. ) was melt-kneaded at 210°C to obtain an extrusion raw material for the resin layer (A). This raw material was extruded through a small T-die extruder (Toyo Seiki Seisakusho C...

Embodiment 2

[0125] Dicing sheets were produced in the same manner as in Example 1, except that the content of the ring-containing resin (a1) in Example 1 was changed to 30.0 parts by mass and the content of the acyclic olefin-based resin (a2) was changed to 70.0 parts by mass. The internal haze value of the obtained resin layer (A) was 29.8%.

Embodiment 3

[0127] Dicing sheets were produced in the same manner as in Example 1, except that the content of the ring-containing resin (a1) in Example 1 was changed to 50.0 parts by mass and the content of the acyclic olefin-based resin (a2) was changed to 50.0 parts by mass. The internal haze value of the obtained resin layer (A) was 47.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile modulus | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com