High-speed omni-directional tracking and monitoring equipment

A monitoring equipment and all-round technology, applied in image data processing, TV, color TV, etc., can solve the problems of increased monitoring cost, irreparable, multi-bandwidth, etc., and achieve the effects of fast processing, improved efficiency, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

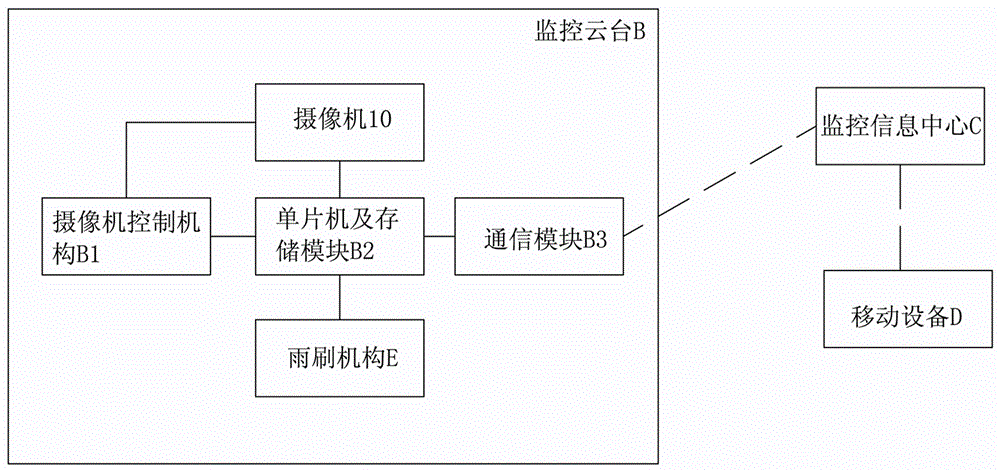

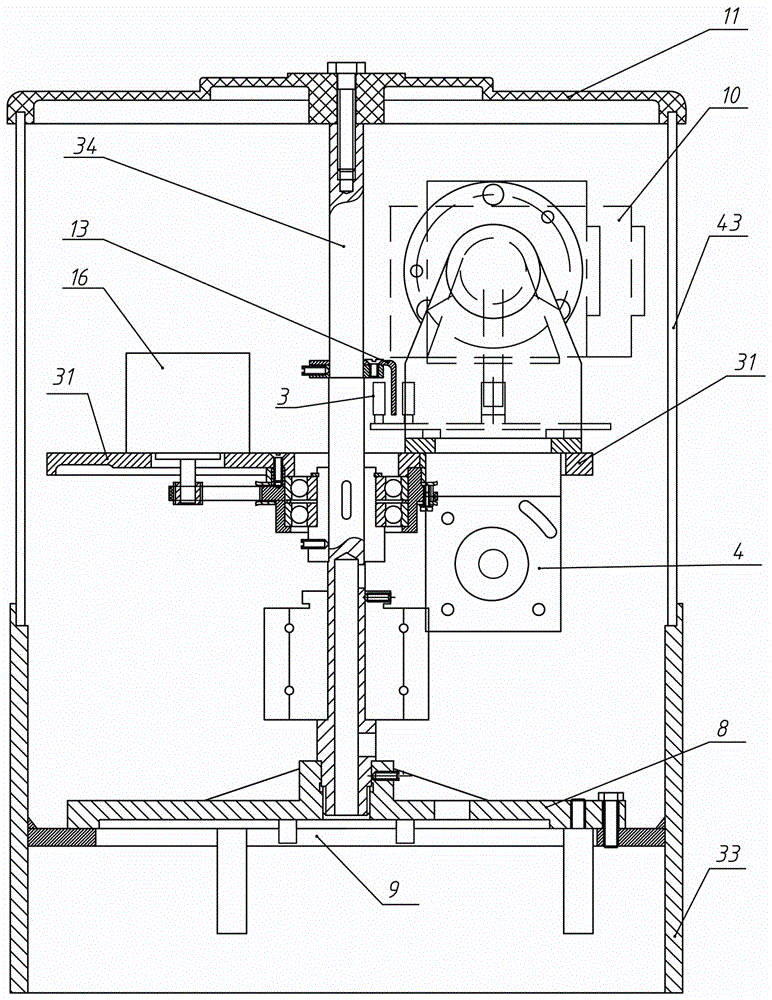

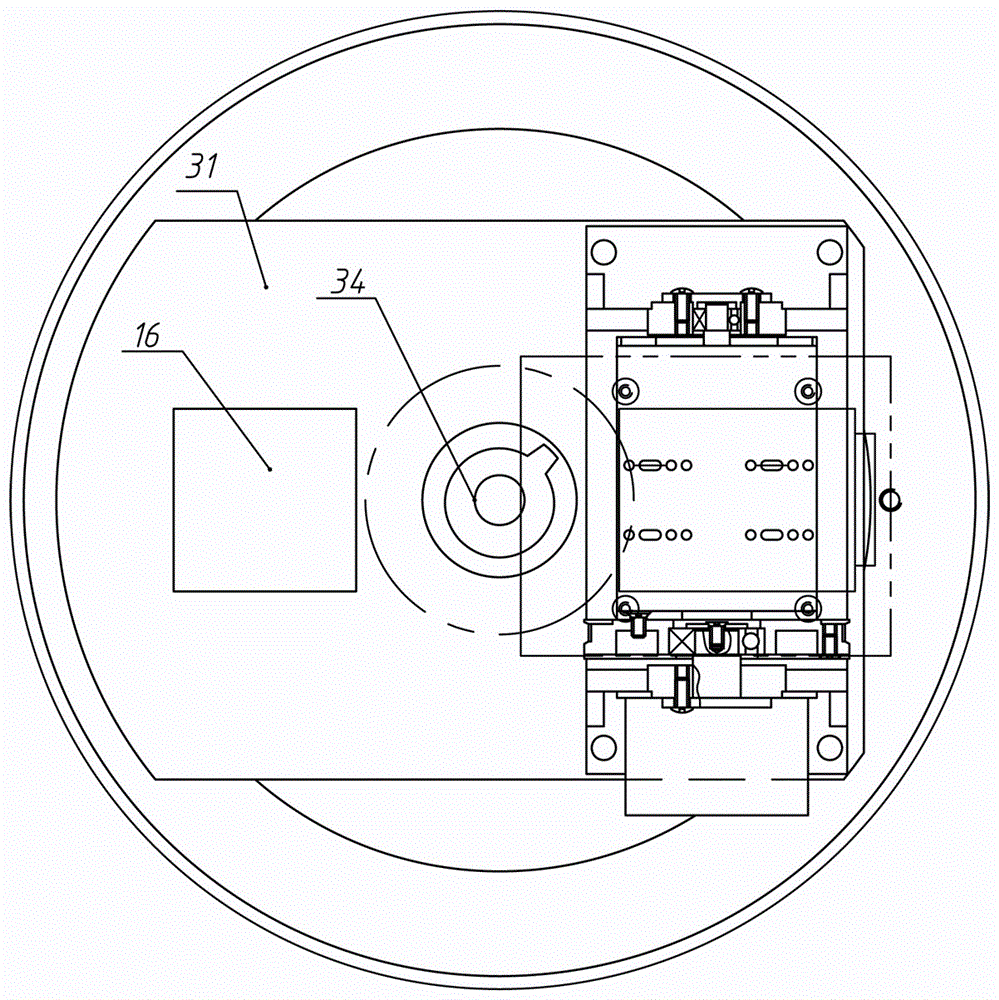

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 An embodiment of the high-speed omni-directional tracking and monitoring equipment shown includes an on-site monitoring camera 10 installed on a monitoring platform B, a monitoring information center C, and a mobile device D. The monitoring pan-tilt B can be fixed on the thin column, and it includes a cylindrical protective case with a bottom plate 9, a camera 10, a camera control mechanism B1, a single-chip microcomputer and a storage module B2, a communication module B3, and a pan-tilt support frame. The monitoring platform B and the mobile device D are connected to the monitoring information center C respectively, and the monitoring platform B obtains the video obtained by the on-site monitoring camera 10 and the position information of the camera 10 and stores them in the single-chip microcomputer and the storage module B2, And send it to the monitoring information center C through the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com