Cement plant SCR denitration efficiency monitoring control method

A technology of denitration efficiency, monitoring and control, applied in various fluid ratio control, separation methods, chemical instruments and methods, etc., can solve the problems of secondary environmental pollution and increase of ammonia gas escape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

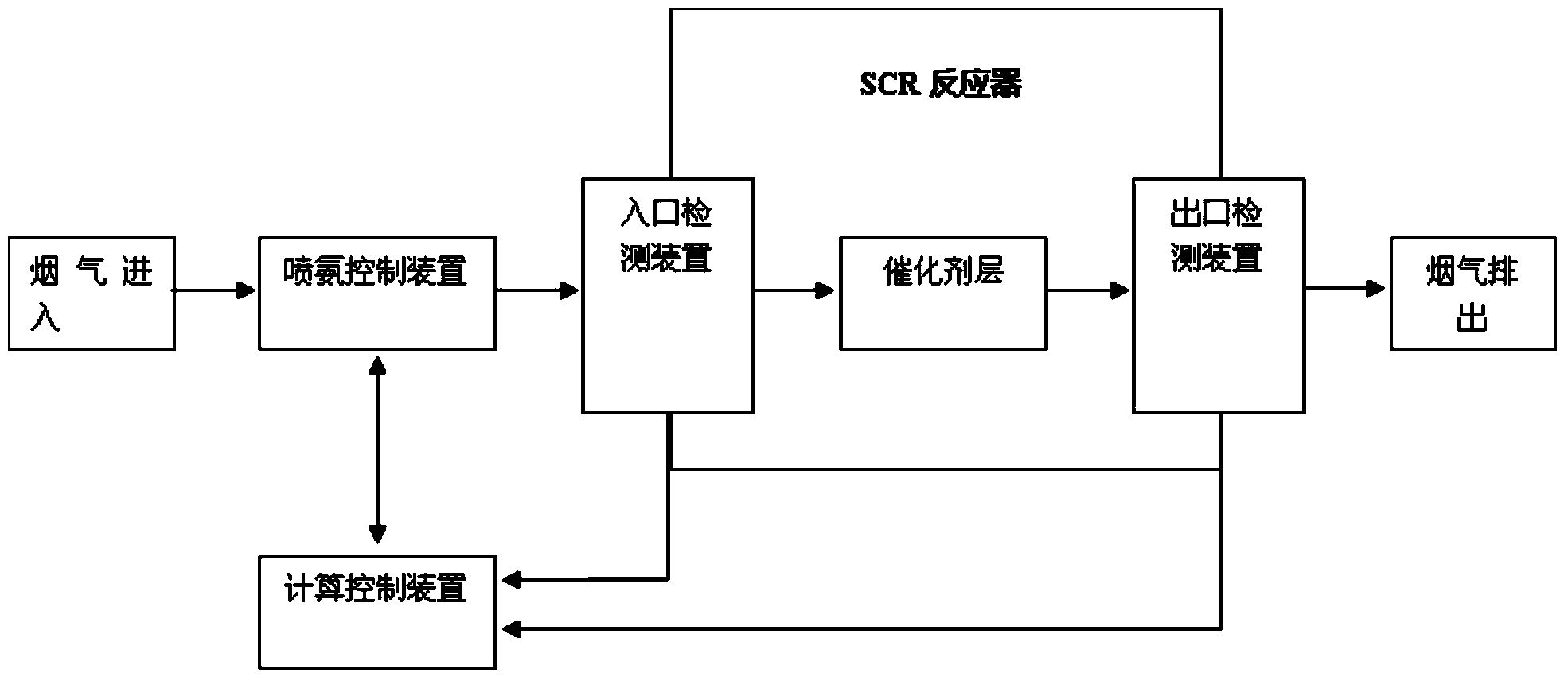

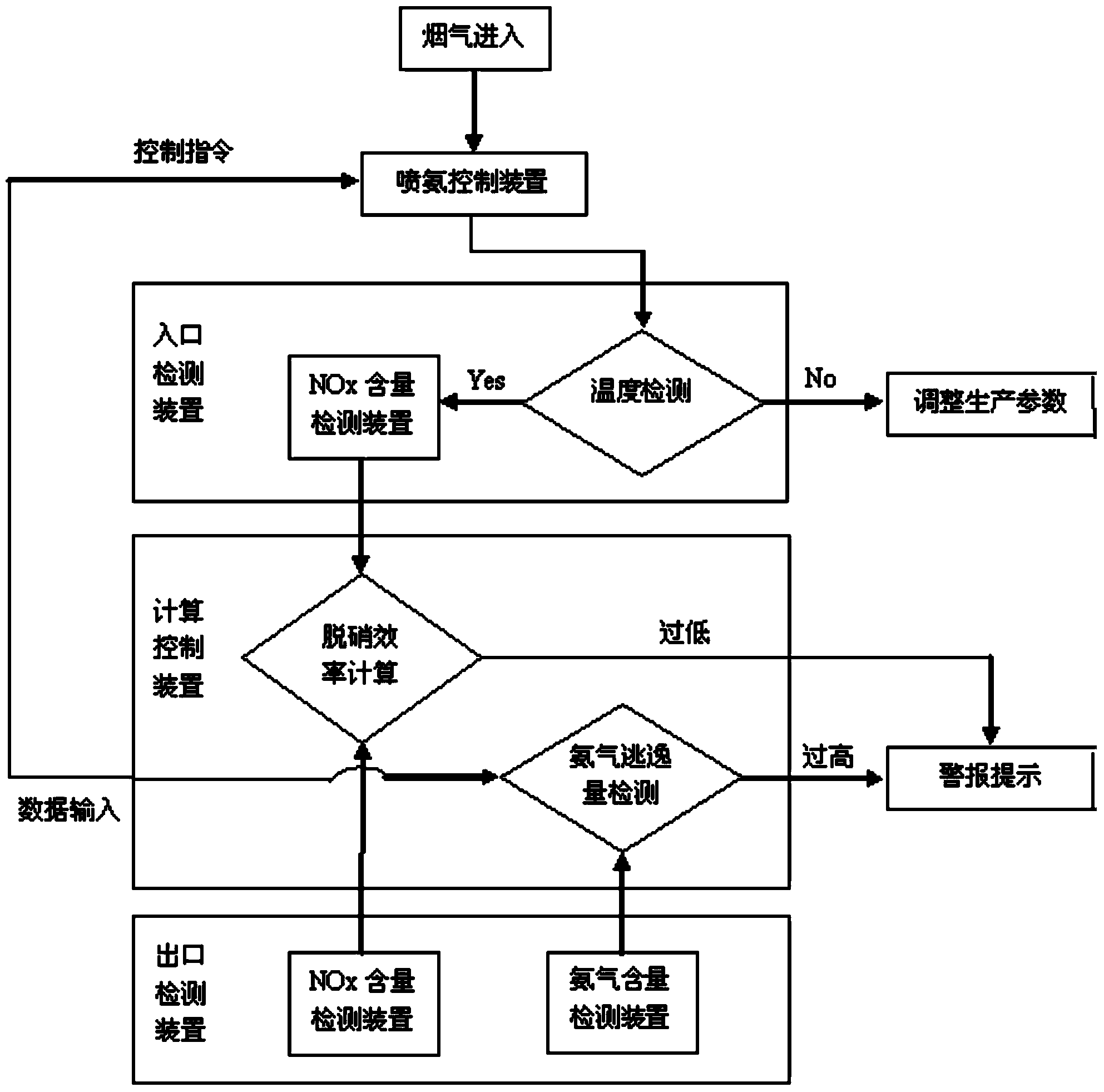

[0029] According to the accompanying drawings in the following figure 1 and figure 2 , and the embodiments further illustrate the control system and control method for the detection of SCR denitrification efficiency in cement plants.

[0030] The design scale of the cement production line in the embodiment is 2500t clinker / day, and the actual output is 2500t clinker / day. The SCR reactor is installed after the waste heat boiler and before the bag filter for coal mill drying. The temperature of the inlet flue is about 200℃, and the total air volume is about 175000m 3 / h, the NOx content in the flue gas is about 600mg / Nm 3 .

[0031] The catalyst in the SCR reactor can use medium and low temperature catalysts, such as MnOx-CeO 2 -TiO 2 type catalyst, the catalytic efficiency can reach more than 90% at around 200°C, and the suitable ammonia nitrogen ratio is 0.9:1.

[0032] SCR reactor denitrification efficiency monitoring and control system in cement plant, including ammo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com