Combined Coal Gasification and Combustion Fluidized Bed-Powdered Coal Furnace in Series

A fluidized bed and pulverized coal furnace technology is applied in fluidized bed combustion equipment, fuels burned in a molten state, and combustion methods, etc., and can solve the problems of inability of simultaneous combustion of fuels, difficulty in stable combustion under low load, and poor adaptability to coal types. , to achieve the effect of reducing power consumption, reducing the formation of nitrogen oxides, and strengthening combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

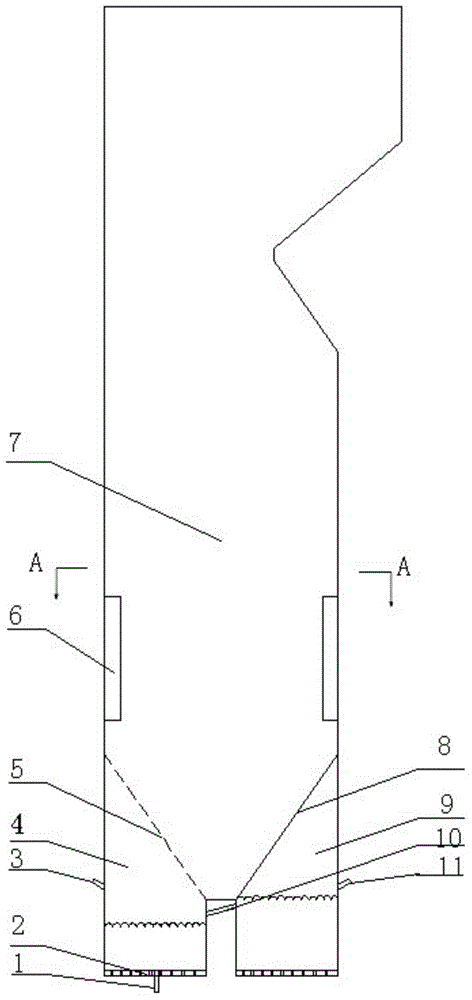

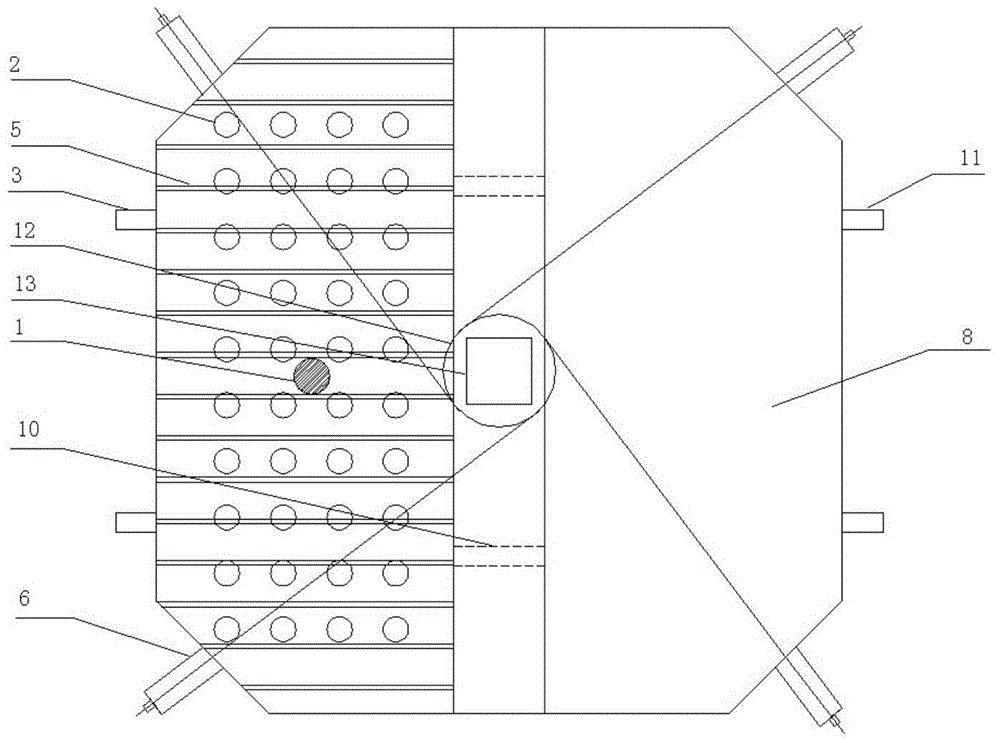

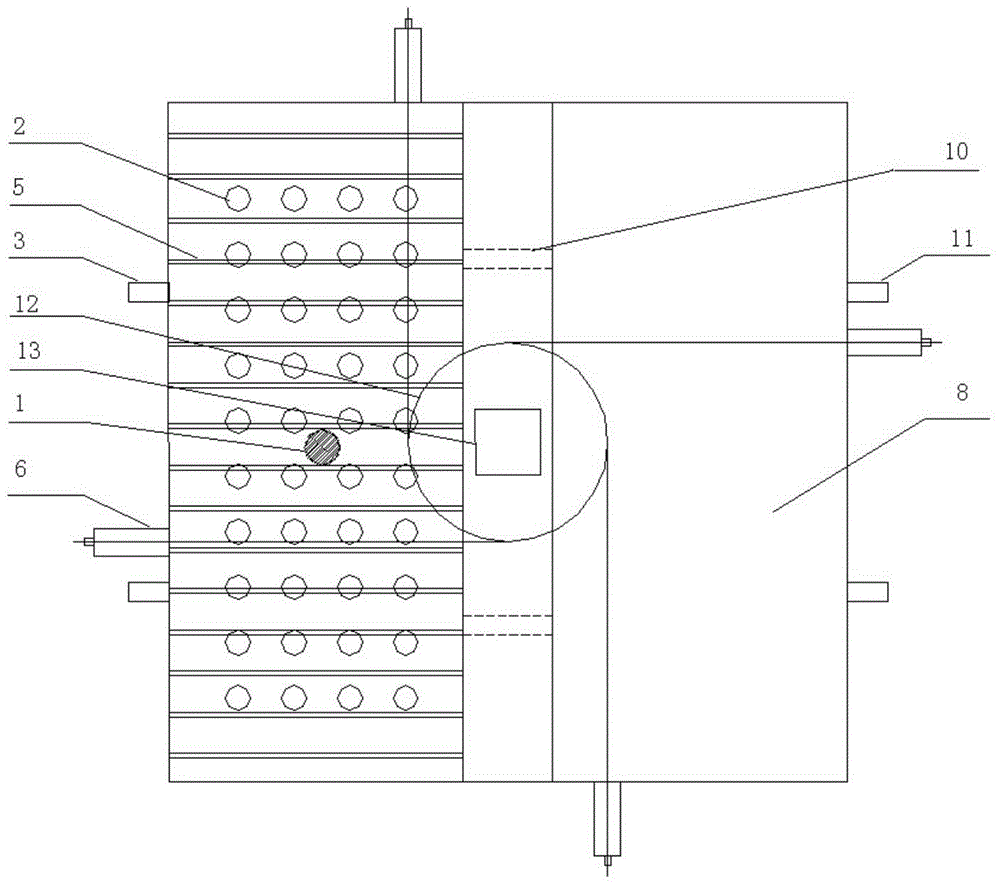

[0018] Specific implementation mode one: combine Figure 1 ~ Figure 3 Describe this embodiment, this embodiment comprises pulverized coal suspension combustion chamber 7, water cooling wall 8, combustion fluidized bed 4, gasification fluidized bed 9, overflow pipe 10, combustion fluidized bed 4 and gasification fluidized bed 9 are positioned at The lower side of the cold ash bucket in the pulverized coal suspension combustion chamber 7, the gasification fluidized bed 9 and the furnace are completely separated by the water wall 8, the gasification fluidized bed 9 and the combustion fluidized bed 4 communicate with each other through the overflow pipe 10, and the combustion The fluidized bed 4 and the furnace are separated by a forked tube bundle 5, forming a gasification fluidized bed 9, a combustion fluidized bed 4 and a pulverized coal suspension combustion chamber 7 connected in series. The forked tube bundle 5 plays a role of isolation, but the gas-solid two-phase flow and ...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination figure 1 This embodiment will be described. The gasification fluidized bed 9 of this embodiment is an independent fluidized bed coal gasifier. The gasification fluidized bed 9 can be turned on or off, which has little effect on the output of the boiler. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0020] Specific implementation mode three: combination figure 1 To describe this embodiment, the coal combustion ratio of the combustion fluidized bed 4 of this embodiment accounts for 20% to 40% of that of the pulverized-coal suspension combustion chamber 7 . This design is conducive to adjusting the boiler compound. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com