Method for preparing epoxy propane

A technology of propylene oxide and propylene, which is applied in the field of preparing propylene oxide, can solve the problems of high energy consumption, poor continuous production capacity, low selectivity of propylene oxide, etc., achieve good technical effect, and reduce catalyst activity and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

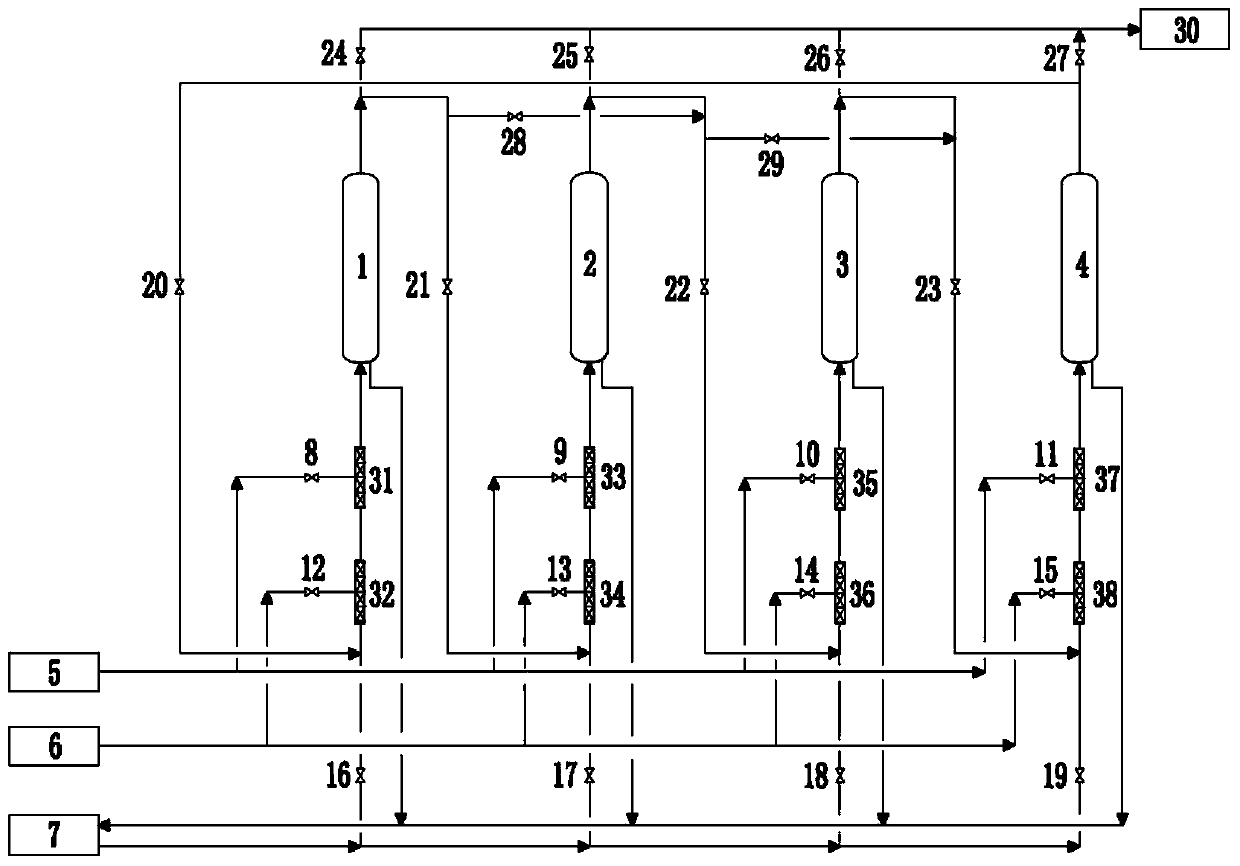

[0021] The following takes four reactors in series as an example to illustrate the operation idea of the method of the present invention.

[0022] in such as figure 1 On the device shown, four fixed-bed reactors are connected in series, and the production scale is 100,000 tons / year.

[0023] Fresh propylene raw material 6 is firstly mixed with methanol solvent 7 in static mixer 32, then fully mixed with fresh hydrogen peroxide raw material 5 through static mixer 31, and then enters reactors 1, 2, 3, and 4 in turn for reaction. Valves 8, 12, 16, 21, 22, 23, and 27 for the switching operation of the reactor are open, and other valves 9, 10, 11, 13, 14, 15, 17, 18, 19, 20, 24, and 25 , 26, 28, 29 are off. After the reaction at the top of reactor 1, the mixture passes through valve 21 in turn, and static mixers 34 and 33 enter reactor 2 from the bottom for reaction. After the reaction at the top of reactor 2, the mixture passes through valve 22 in turn, and static mixers 36 an...

Embodiment 2

[0028] According to the conditions and steps described in Example 1, the production scale is 200,000 tons / year, and the temperatures of the four reactors are respectively 50°C, 45°C, 40°C, and 35°C; the reaction pressure is 2.2MPaG; the weight space velocity of propylene 1.8h -1 ; The molar ratio of methanol / hydrogen peroxide is 8:1; the molar ratio of propylene / hydrogen peroxide is 3:1. The results show that the selectivity of propylene oxide reaches above 97.0%, and the purity of propylene oxide product reaches above 99.95%. Propylene consumption is 149,232.14 tons / year, saving 1,554.50 tons / year of propylene; hydrogen peroxide consumption is 120,806.97 tons / year, saving 1,258.40 tons / year of hydrogen peroxide.

Embodiment 3

[0030] According to the conditions and steps described in Example 1, the production scale is 300,000 tons / year, and the temperatures of the four reactors are respectively 55°C, 50°C, 45°C, and 40°C; the reaction pressure is 2.5MPaG; the weight space velocity of propylene for 3.0h -1; The molar ratio of methanol / hydrogen peroxide is 10:1; the molar ratio of propylene / hydrogen peroxide is 5:1. The results show that the selectivity of propylene oxide reaches above 97.0%, and the purity of propylene oxide product reaches above 99.95%. The consumption of propylene is 223848.20 tons / year, saving 2331.76 tons / year of propylene; the consumption of hydrogen peroxide is 181210.45 tons / year, saving 1887.61 tons / year of hydrogen peroxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com