Fine fraction ilmenite flotation-gravity separation combined technology

A combined process and ilmenite technology, which is applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems that the best effect cannot be achieved, the recovery and utilization rate of fine-grained ilmenite is not ideal, and achieve The effect of solving serious loss and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

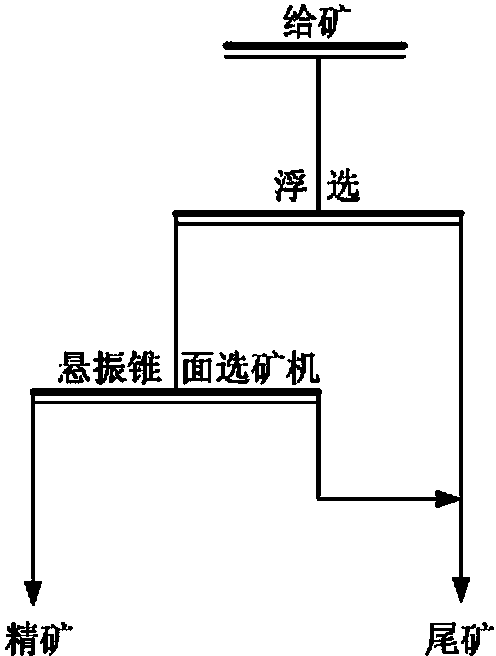

[0009] Embodiment 1: Raw material originates from ilmenite in a certain place, TiO 2 The content is 7.8%, and the process flow diagram is as follows: figure 1 The method shown is carried out. Styrene phosphonic acid is used as collector, sulfuric acid is used as regulator, the dosage is 900g / t of ilmenite, styrene phosphonic acid accounts for 900g / t of ilmenite, sulfuric acid is used to adjust the pH value to 6.13, and the grade of crude concentrate is 20.3%. The rate is 70.27%. Then use a Φ4m suspension vibrating cone concentrator for selection, the taper of the sorting surface is 7°, the vibration frequency is 400 times / min, and the speed is 1.4 m / min, and finally the concentrate of the suspension vibrating cone concentrator is obtained. The grade is 38%, and the recovery rate is 45.31%. A better beneficiation index has been achieved. The following tables 1 and 2 are the results of flotation and re-election in this embodiment respectively.

[0010] Table 1:

[0011] ...

Embodiment 2

[0014] Embodiment 2: raw material originates from ilmenite in a certain place, TiO 2 The content is 12.6%, and the process flow diagram is as follows: figure 1 The method shown is carried out. Emulsified tall oil is used as collector, carboxymethyl cellulose, water glass and sulfuric acid are used as regulators, the amount of emulsified tall oil is 800g / t of ilmenite, and the sum of carboxymethyl cellulose, water glass and sulfuric acid Accounting for 900g / t of ilmenite, the grade of crude concentrate obtained is 23%, and the recovery rate is 80.32%. Then use a Φ4m suspension vibrating cone concentrator for beneficiation. The taper of the sorting surface is 7°, the vibration frequency is 410 times / min, and the speed is 2.0 m / min. Finally, the titanium concentrate of the suspension vibrating cone concentrator is obtained. The concentrate grade is 45%, and the recovery rate is 64.29%. A better beneficiation index has been achieved. The following tables 3 and 4 are the result...

Embodiment 3

[0019] Embodiment 3; Raw material originates from ilmenite in a certain place, TiO 2 The content is 13.06%, and the process flow diagram is as follows figure 1 The method shown is carried out. Adopt oxidized paraffin soap to make collector, sulfuric acid is made adjustment agent, consumption is that oxidized paraffin soap accounts for 800g / t of ilmenite, and sulfuric acid accounts for 850g / t of ilmenite, obtains coarse concentrate grade and is 24%, and the recovery rate is 79.02%. Then use a Φ4m suspension vibrating cone concentrator for beneficiation. The taper of the sorting surface is 7°, the vibration frequency is 430 times / min, and the speed is 1.6 m / min. Finally, the titanium concentrate of the suspension vibrating cone concentrator is obtained. The concentrate grade is 48%, and the recovery rate is 55.31%. A better beneficiation index has been obtained. Tables 5 and 6 below are the results of flotation and re-election in this embodiment, respectively.

[0020] tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com