Lithium ion battery anode and preparation method thereof

A lithium-ion battery and positive electrode technology, applied in battery electrodes, battery components, circuits, etc., can solve the problems of low mechanical strength, low film-making efficiency, and film size limitation, and achieve low quality and high film-making efficiency , the effect of increasing energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of the positive electrode of the button battery: Spray 30% alcohol aqueous solution on the glass substrate (20cm×20cm) and the glass rod, and pull the macroscopic tube continuum formed from the reactor port to the square glass substrate with the glass rod. In the form of vertical and horizontal graticules, a carbon nanotube film with a thickness of about 10 μm will be obtained on the glass substrate. The active material (LiCoO 2 ), conductive agent (Super-P), binder (polyvinylidene fluoride) mixed with NMP at a ratio of 90:4:6 (solid content kept at 45%), and put into a ball mill for ball milling for 10 hours at a speed of 232rmin -1 , to obtain positive electrode slurry. Keep the edge of the scraper at 180 μm, apply a layer of slurry evenly on the film, and put it in an oven at 120°C for 40 minutes. Subsequently, lay the glass substrate with the coated carbon nanotube film layer flat, dip the NMP with a brush, and brush lightly on the area of the carbon...

Embodiment 2

[0031] Preparation of the positive electrode of single-layer laminated battery: Spray 30% alcohol aqueous solution on the glass substrate (20cm×36cm) and the glass rod, and pull the macroscopic tube continuum formed from the reactor port to the square glass substrate with the glass rod . In the form of vertical and horizontal graticules, a carbon nanotube film with a thickness of about 13 μm will be obtained on the glass substrate. The active material (LiCoO 2 ), conductive agent (Super-P), binder (polyvinylidene fluoride) mixed with NMP in a ratio of 90:4:6 (solid content 45%), put into a ball mill for 12 hours, and the speed is 232rmin -1 , to obtain positive electrode slurry. The method of "knife moving and film fixing" is adopted, that is, the glass plate carrying the film does not move, the scraper moves the knife on the film with a 230 μm knife edge, and the positive electrode slurry is coated on the carbon nanotube film in the "gap coating" method. The size of each c...

Embodiment 3

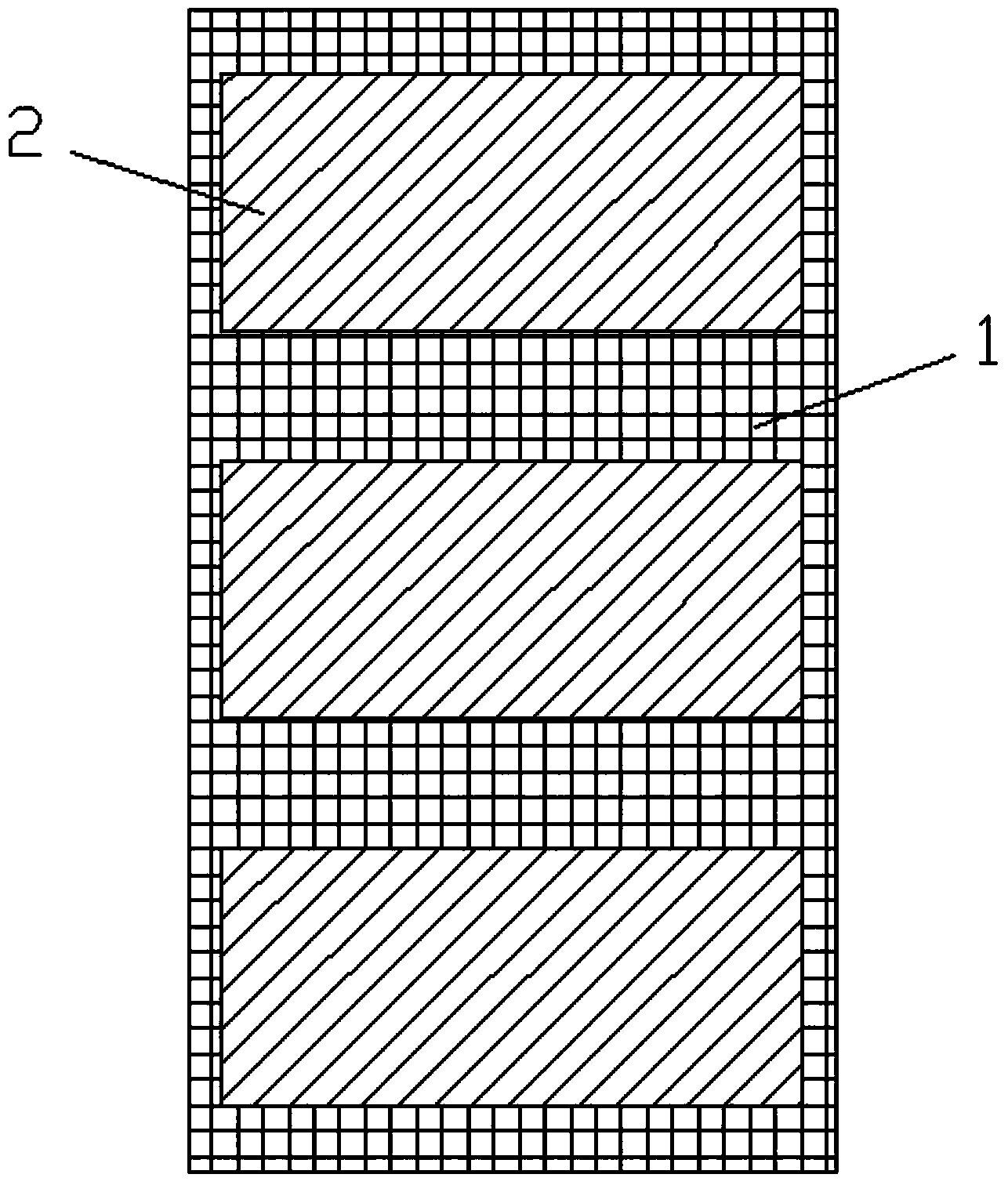

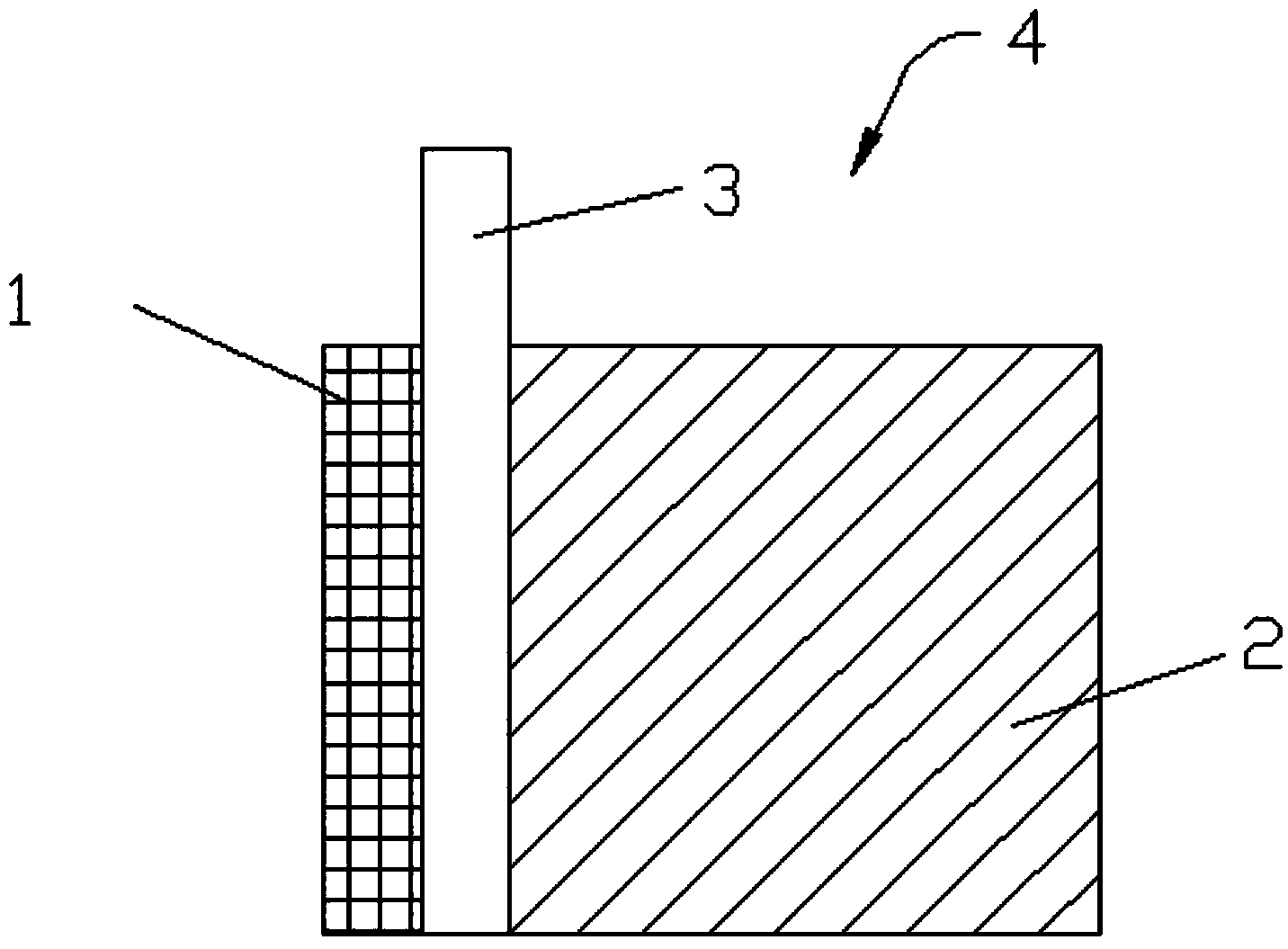

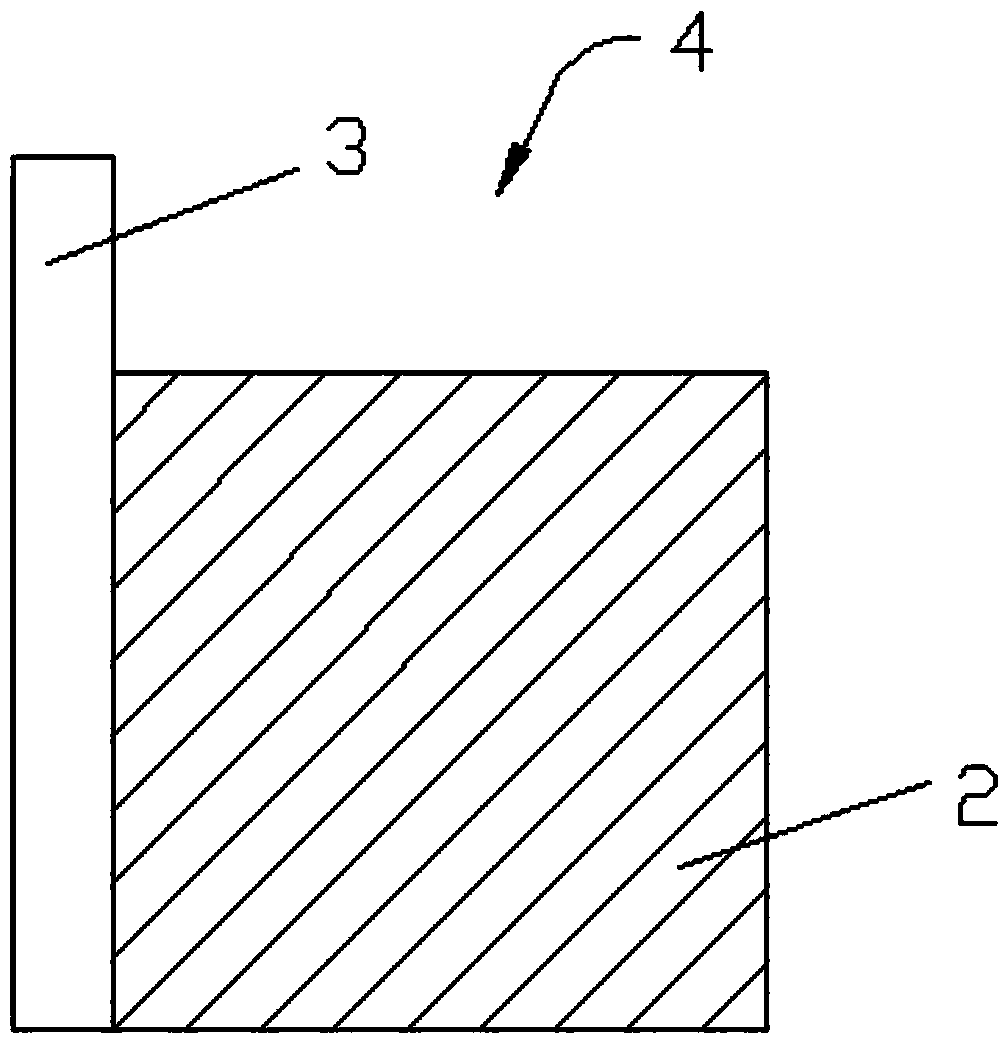

[0033] Preparation of positive electrode of multi-layer laminated battery: Spray 30% alcohol aqueous solution with volume fraction on glass substrate (20cm×36cm) and glass rod, and pull the macroscopic tube continuum formed from the reactor port to square glass substrate with glass rod . A carbon nanotube film with a thickness of about 13 μm will be obtained on the glass substrate in the form of vertical and horizontal graticules. The active material (LiCoO 2 ), conductive agent (Super-P), binder (polyvinylidene fluoride) mixed with NMP in a ratio of 90:4:6 (solid content 45%), and put into a ball mill for 12 hours at a speed of 248rmin -1 , to obtain positive electrode slurry. Using the method of "knife moving film fixed", the scraper moves the knife on the film with a 230μm knife edge, and coats the positive electrode slurry on the carbon nanotube film in gaps. The size of each coating is 8cm×18cm, and the gap width is 4cm. The specific situation See figure 1 . After co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mechanical strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com