Silane sampling system adopting gas chromatography and method thereof

A technology of sampling system and sampling system, which is applied in the analysis field of industrial production of silane, achieves the effects of short analysis period, fulfillment of analysis requirements, and safe and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

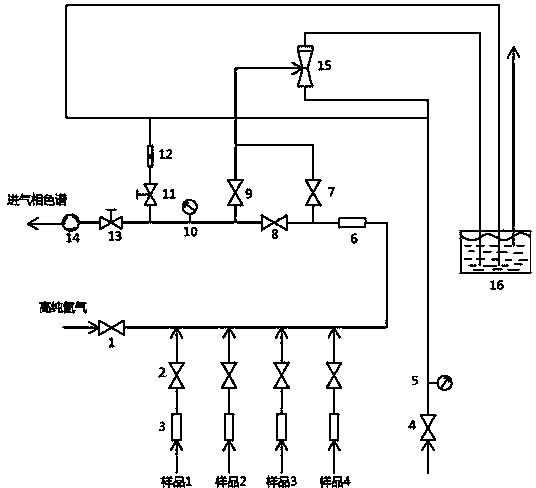

[0046] Implementation example 1: design and installation of silane sampling system

[0047] 1. Use 316L stainless steel pipes to connect multiple detection points in the process with the sampling pipeline of the sampling system. Pipelines are connected by welding, and pipelines, valves and filters are connected by gold-plated ferrules.

[0048] 2. Connect cylinder helium gas at the front end of the sampling pipeline, which can purge the whole pipeline. The purity of helium is required to be greater than 99.999% in volume percentage.

[0049] 3. Install a helium purge valve at the back end of the injection line, and adjust the injection pressure to stabilize at 0.05MPa.

[0050] 4. Connect a venting bypass at the end of the sampling line, use a needle valve to adjust the venting flow rate, which is required to reach 300-500ml / min venting flow rate, and quickly replace the residual sample between the sampling point and the sampling system to extract to a representative sample...

Embodiment 2

[0053] Implementation Example 2: Using the sampling system to sample and analyze silane standard gas

[0054] 1. Silane standard gas 1 component: nitrogen: 50.1ppm; silane balance gas;

[0055] 2. Connect the silane standard gas cylinder to the sampling system from the inlet of sample 1, open the second vacuum valve 9 to vacuum the sampling system for 30 seconds, close the second vacuum valve 9, open the helium purge valve 1, and use high Purging with pure helium for 3 minutes. Repeat the above operation 3 times.

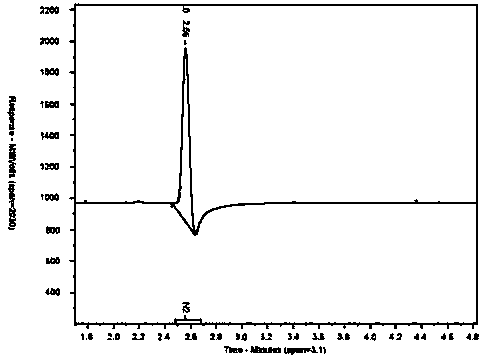

[0056] 3. Open the sample injection valve 2, let the silane standard gas 1 enter the sampling system, adjust the silane injection pressure to 0.05MPa, adjust the silane injection flow rate to 50ml / min, use the six-way quantitative valve 14 to quantify, and control the injection volume to 1ml into the gas chromatographic analysis, the analysis spectrum is as follows image 3 .

Embodiment 3

[0057] Implementation example 3: Connect another bottle of silane standard gas to verify the purging and replacement effect of the sampling system during switching analysis.

[0058] 1. Silane standard gas 2 components: Nitrogen: 2.9ppm; Silane balance gas;

[0059] 2. Connect the silane standard gas cylinder to the sampling system from the sample 2 inlet, open the second vacuum valve 9 and vacuum the sampling system for 30 seconds, close the second vacuum valve 9, and open the helium purge valve 1 to purge 3 minutes, with helium purge. Repeat the above operation 3 times. The previously analyzed silane standard gas 1 is purged and replaced.

[0060] 3. Open the sampling valve of sample 2, let the silane standard gas 2 enter the sampling system, adjust the silane sampling pressure to 0.05MPa, adjust the silane sampling flow rate to 50ml / min, open the inlet gas chromatography needle valve 13, and make the silane standard gas 2 enter the sampling system. Gas 2 enters the gas c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com