Brake system for movable rear wall

A brake system and furnace body technology, applied in the field of brake systems, can solve the problems of high equipment investment cost, large heating furnace space, waste of energy, etc., and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

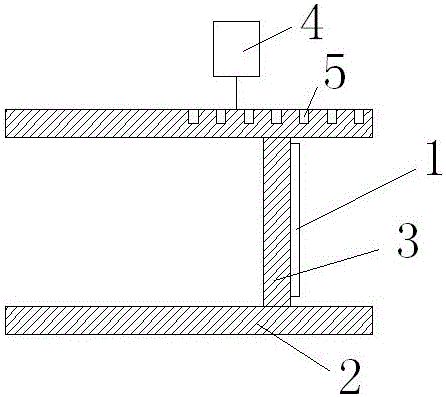

[0009] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0010] As shown in the figure, the brake system of the movable rear wall of the present invention includes a brake system 1, a furnace body 2 and a movable rear wall 3, and the brake system 1 is installed on the outer lower edge of the movable rear wall 3 , the braking system 1 is controlled by a controller 4, and a light sensing system 5 is arranged on the side wall of the furnace body 2, and the light sensing system 5 is electrically connected to the controller 4; the light sensing system 5 There are a plurality of them, and they are evenly arranged side by side on the side wall of one side of the furnace body 2 .

[0011] The movable rear wall can change the size of the space in the furnace body to meet different requirements. The brake system is used to brake the moving rear wall. Since the rear wall is relatively heavy, it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com