Electrically controlled fuel gas mixer

A gas mixer and mixer technology, applied in electrical control, engine control, combustion engine, etc., can solve the problems of large variation range of gas methane content, unguaranteed air-fuel ratio, unsuitable performance of the mixer, etc., and achieve easy adjustment , easy air-fuel ratio, guaranteed start-stop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further disclose the technical solution of the present invention, the following will be elaborated in detail through the embodiments in conjunction with the accompanying drawings:

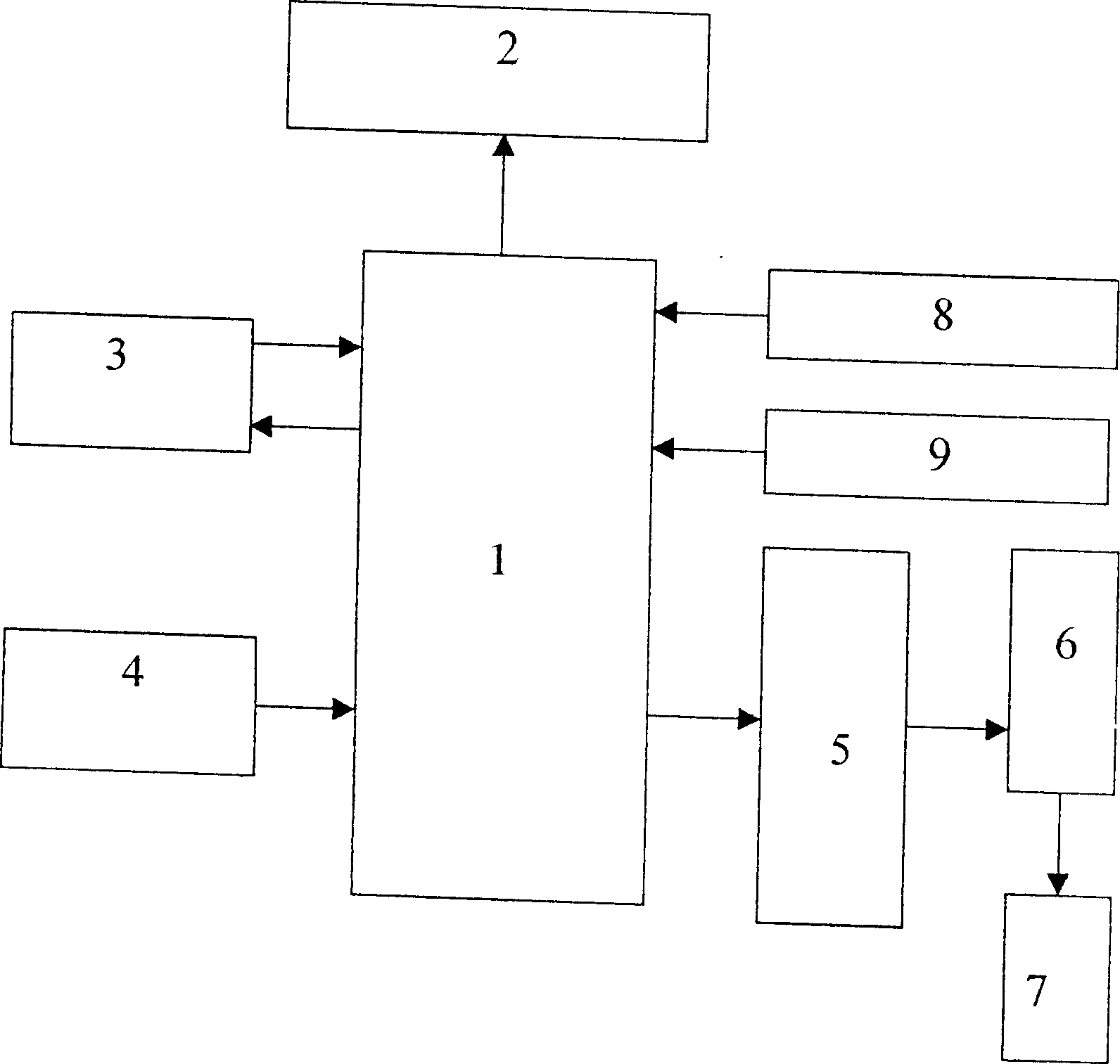

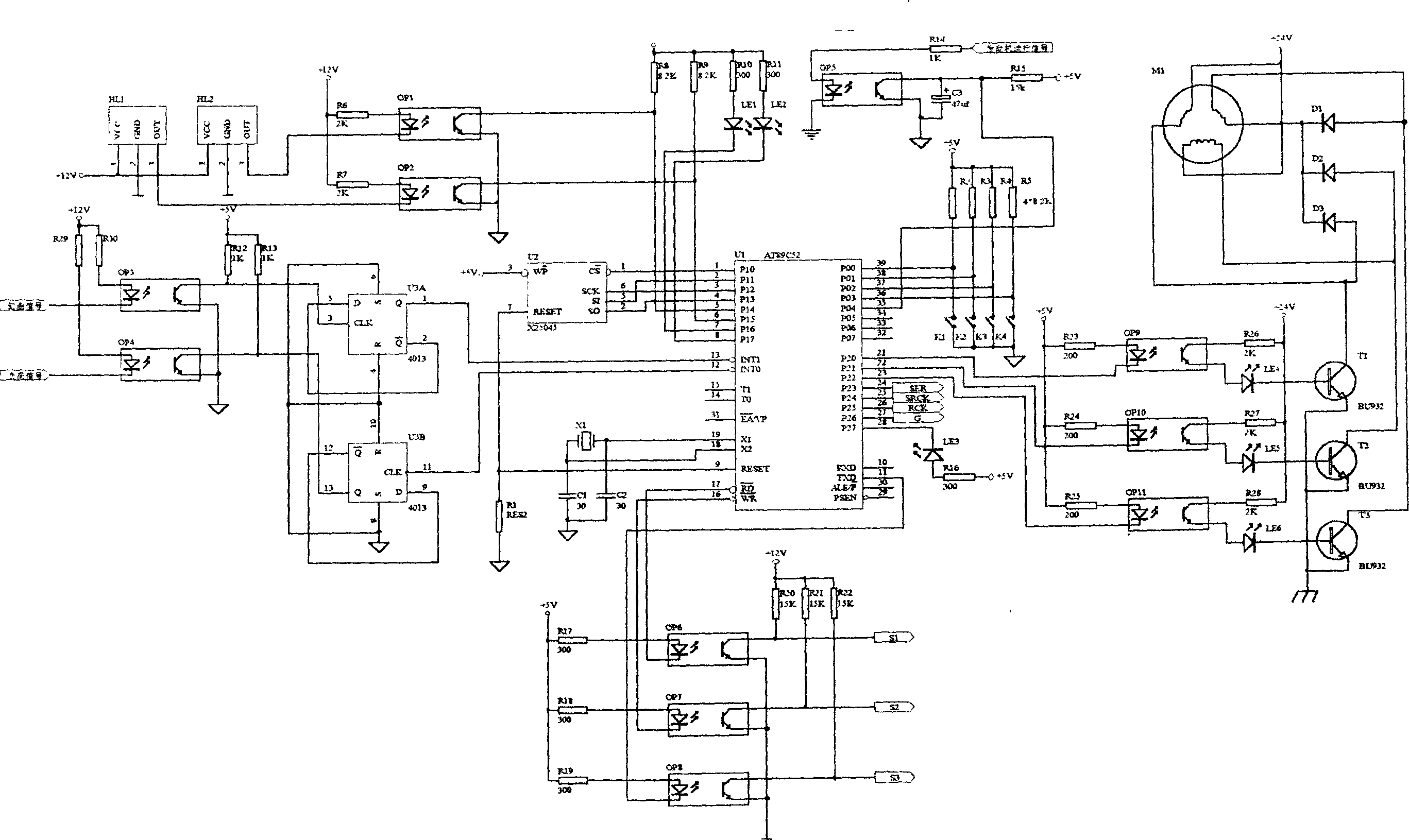

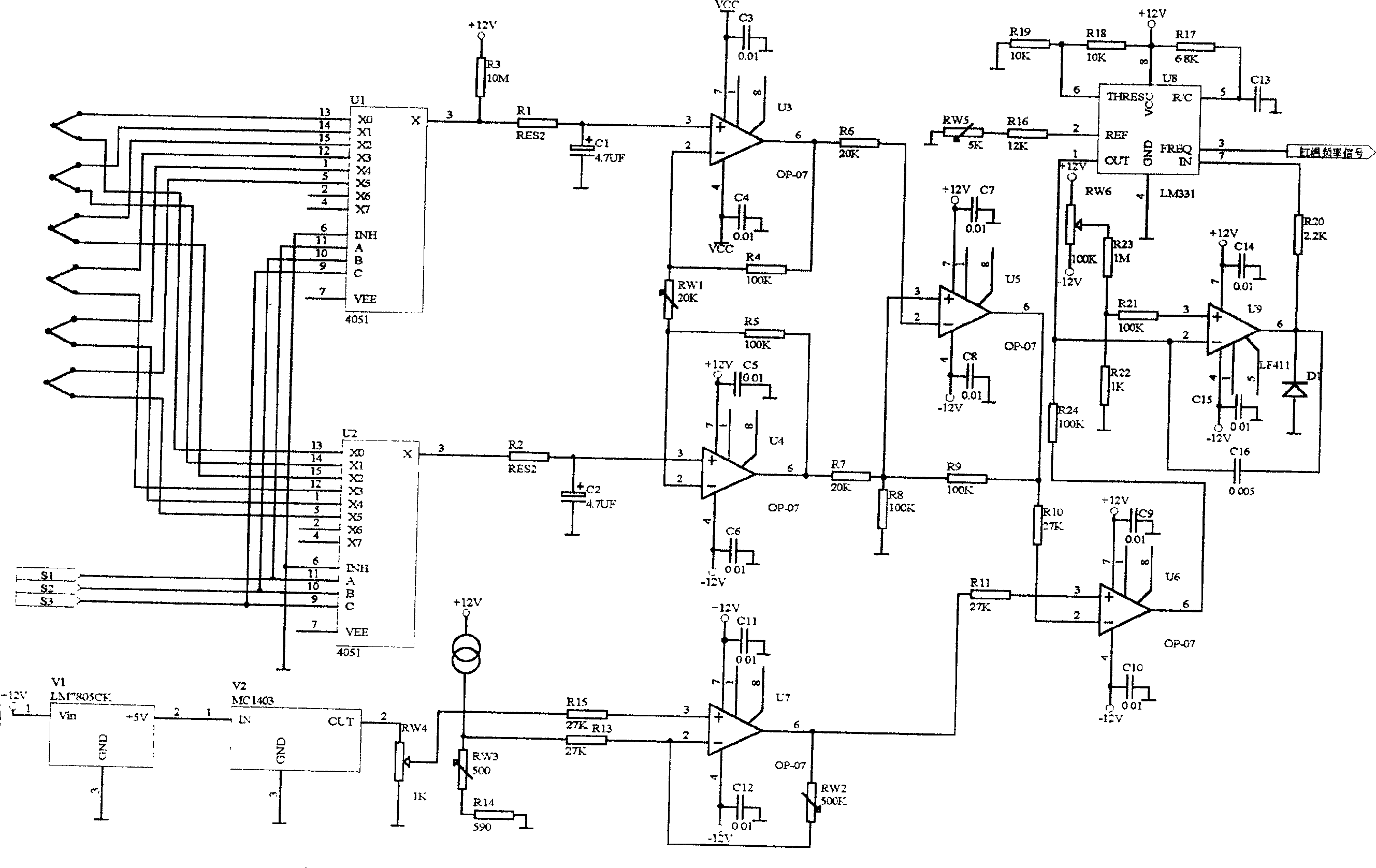

[0026] figure 1 The signal of the middle cylinder temperature measurement circuit 3, the signal of the starting right load circuit 4, the signal of the upper limit switch circuit 8 (by figure 2 HL in 1 and OP 2 circuit) and the signal of the lower limit switch circuit 9 (by figure 2 HL in 2 and OP 1 circuit resistance into) each input central processing unit 1 (by figure 2 Middle U 1 and U 2 circuits and peripheral circuits), the signals processed by the central processor are respectively input to the parameter display circuit 2 ( Figure 5 parameter display circuit) and stepper motor drive circuit and 5 ( figure 2 Medium OP 9 , OP 10 , OP 11 , T 1 , T 2 , T 3 , and other circuits). Make the stepper TV 6 start and stop, thereby controlling the adjustment of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com