A semi-active suspension device for an engine

A semi-active suspension and engine technology, applied in the field of auto parts, can solve the problems of unreliable reliability, poor high-frequency vibration damping effect, high cost, etc., achieve no obvious hysteresis phenomenon, ensure reliability and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

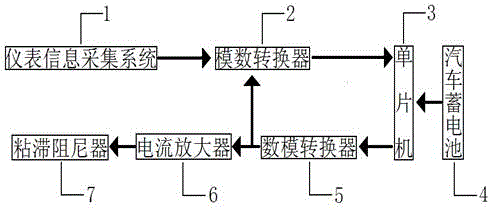

[0022] like figure 1 Shown: the device of the present invention mainly comprises: 1, instrument information collection system; 2, analog-to-digital converter; 3, single-chip microcomputer; 4, automobile battery; damper.

[0023] The device of the invention satisfies the vibration reduction requirements of the engine under different characteristics such as high-frequency small amplitude and low-frequency large amplitude by smoothly and continuously changing the internal damping force of the suspension.

[0024] The device of the present invention uses the battery 4 of the automobile as the energy source, and the instrument information collection system 1 is connected to the automobile instrument circuit to collect the current signal 8 of the automobile tachometer circuit, and the current signal 8 is converted into a digital signal 9 by the analog-to-digital converter 2. , the single-chip microcomputer 3 processes the digital signal 9 so as to judge the vibration frequency of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com