Multi-mode magneto-rheological vibration isolator for passenger car engine

An engine and vibration isolator technology, applied in shock absorbers, shock absorbers, mechanical equipment, etc., can solve the problems of vibration isolation frequency range and small controllable range of dynamic stiffness, and achieve wide vibration isolation range and reliable working performance. , the effect of improving work safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

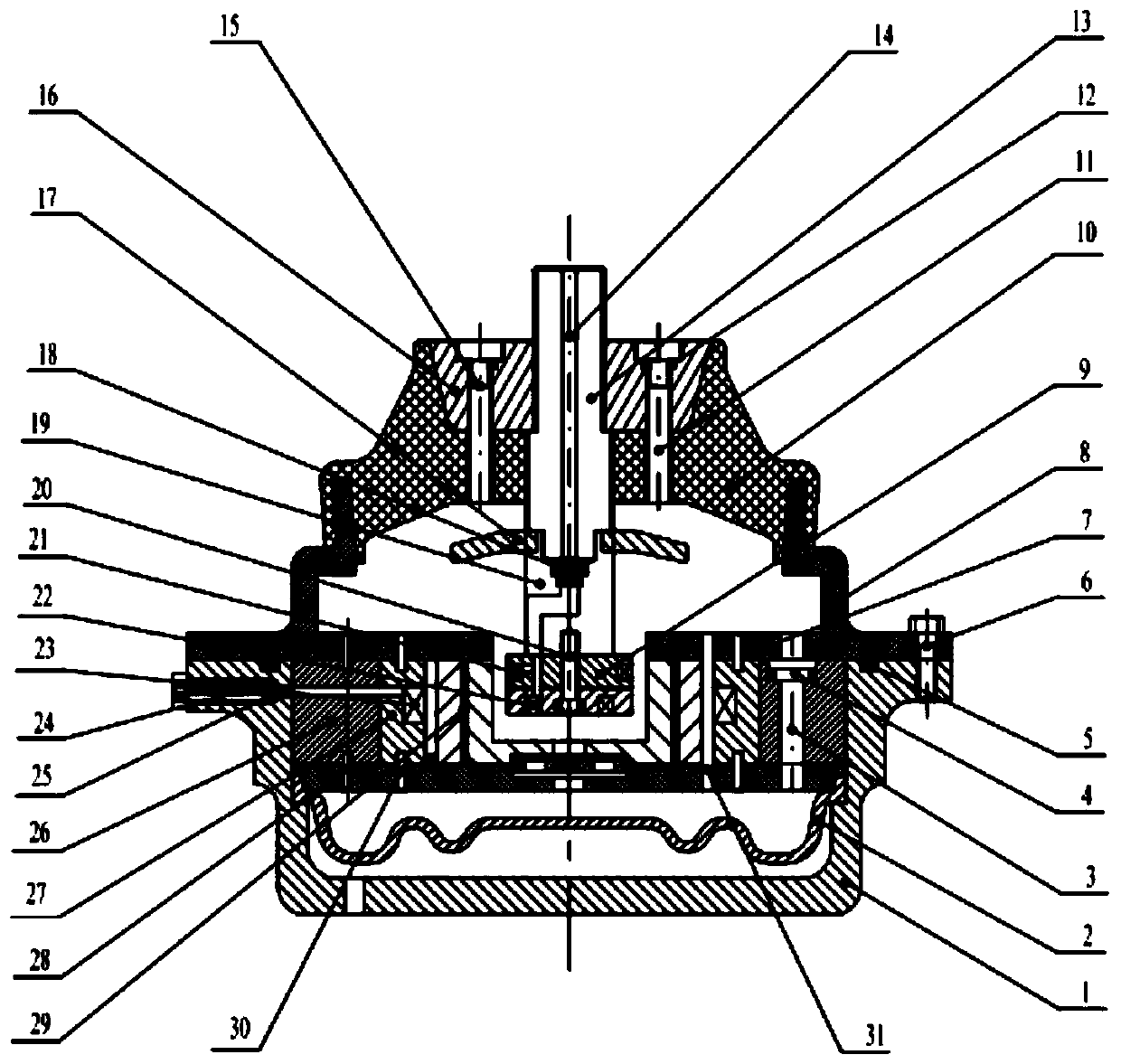

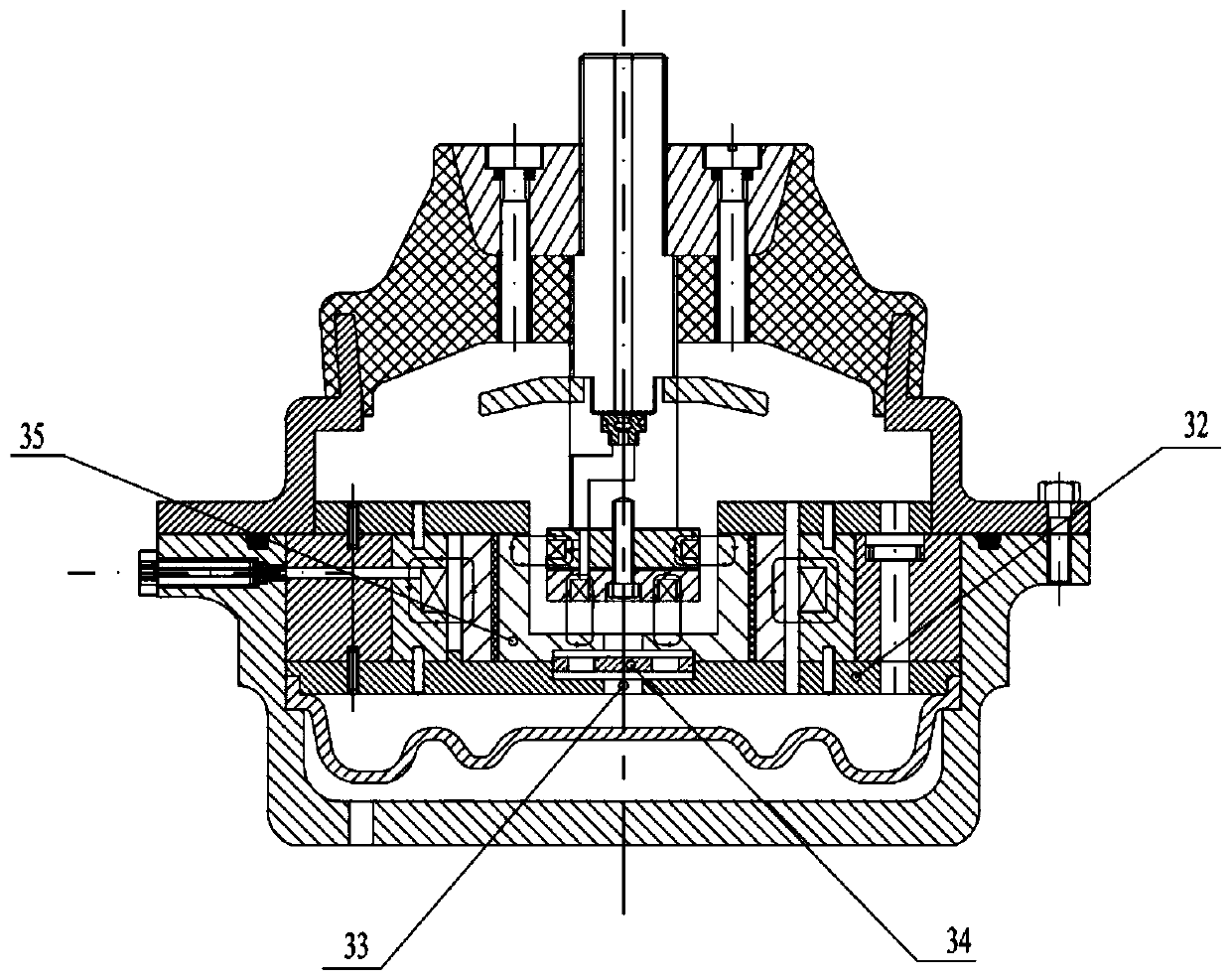

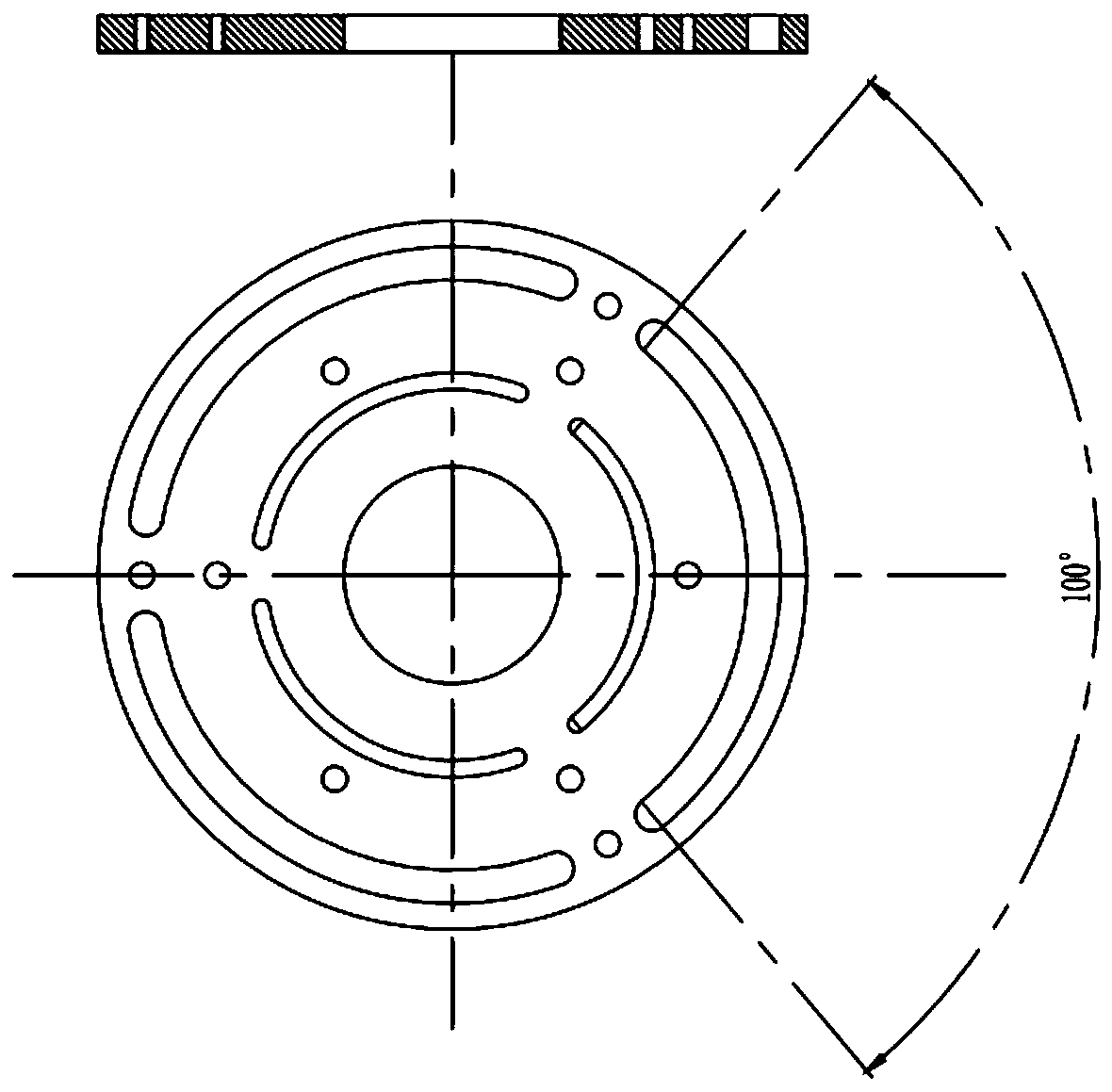

[0034] As shown in the figure, the passenger car engine multi-mode magneto-rheological vibration isolator in this embodiment; a magneto-rheological vibration isolator of a flow, extrusion and shearing combined mode of the present invention includes an upper The housing, the rubber main spring 10 that is arranged and blocked at the top opening of the upper housing 8, the connecting rod 13 that runs through the rubber main spring and the rubber bottom film 2 that is arranged on the inner bottom of the lower housing 1, the rubber main spring and A closed chamber (including an upper chamber and a lower chamber) is formed between the rubber bottom films, and the magnetic core assembly is arranged in the chamber, and the magnetic core assembly includes an upper squeeze from the inside to the outside. The magnetic core 9 and the lower extruded magnetic core (not labeled), the inner magnetic core seat 35 fixed between the upper magnetic isolation plate 7 and the lower magnetic isolatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com