A Composite Structure Phononic Crystal Vibration Isolation Support

A technology of phononic crystals and vibration isolation bearings, which is applied in the field of composite structure phononic crystal vibration isolation bearings, can solve the problems of general vibration isolation effect, narrow vibration isolation frequency range, and single vibration isolation direction, so as to solve the problem of singleness , meet the vibration isolation requirements, and increase the effect of vibration isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

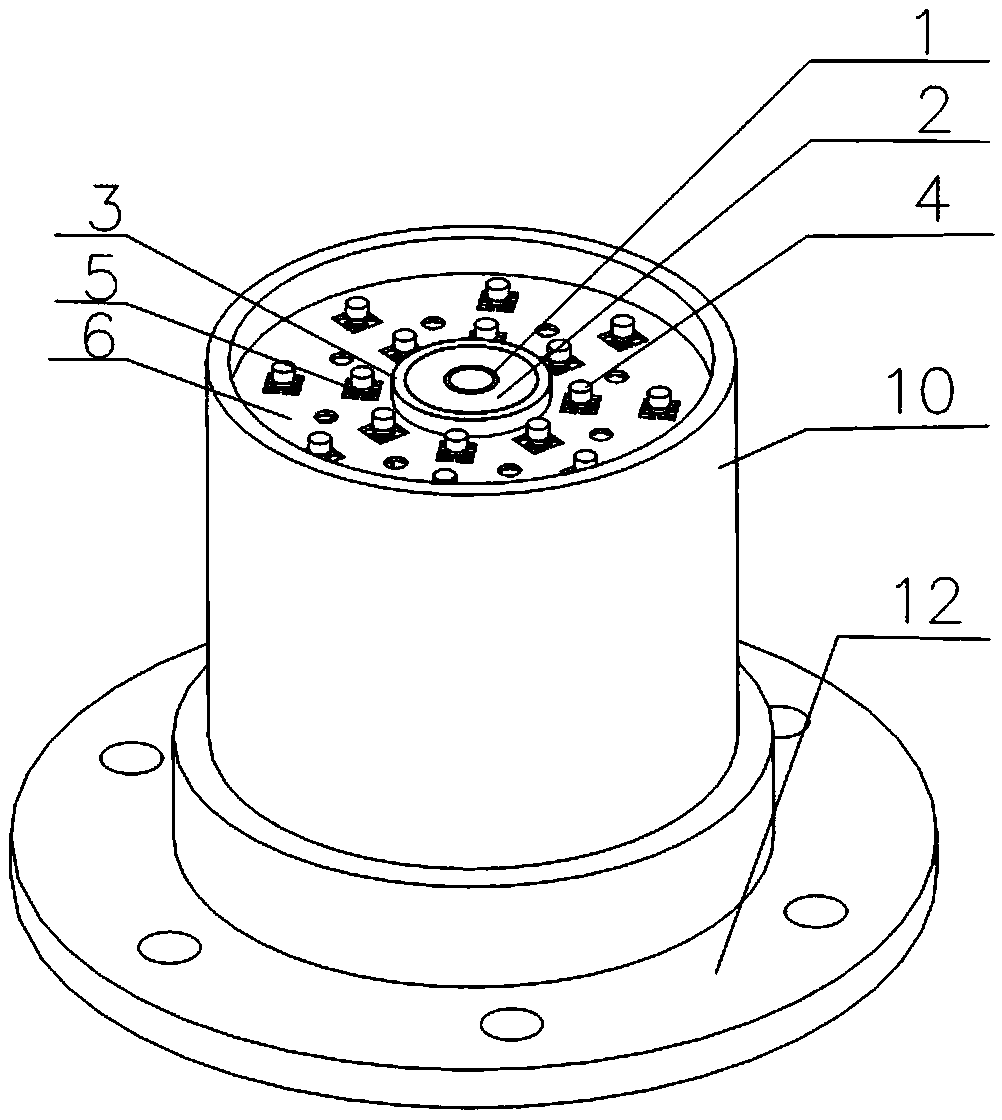

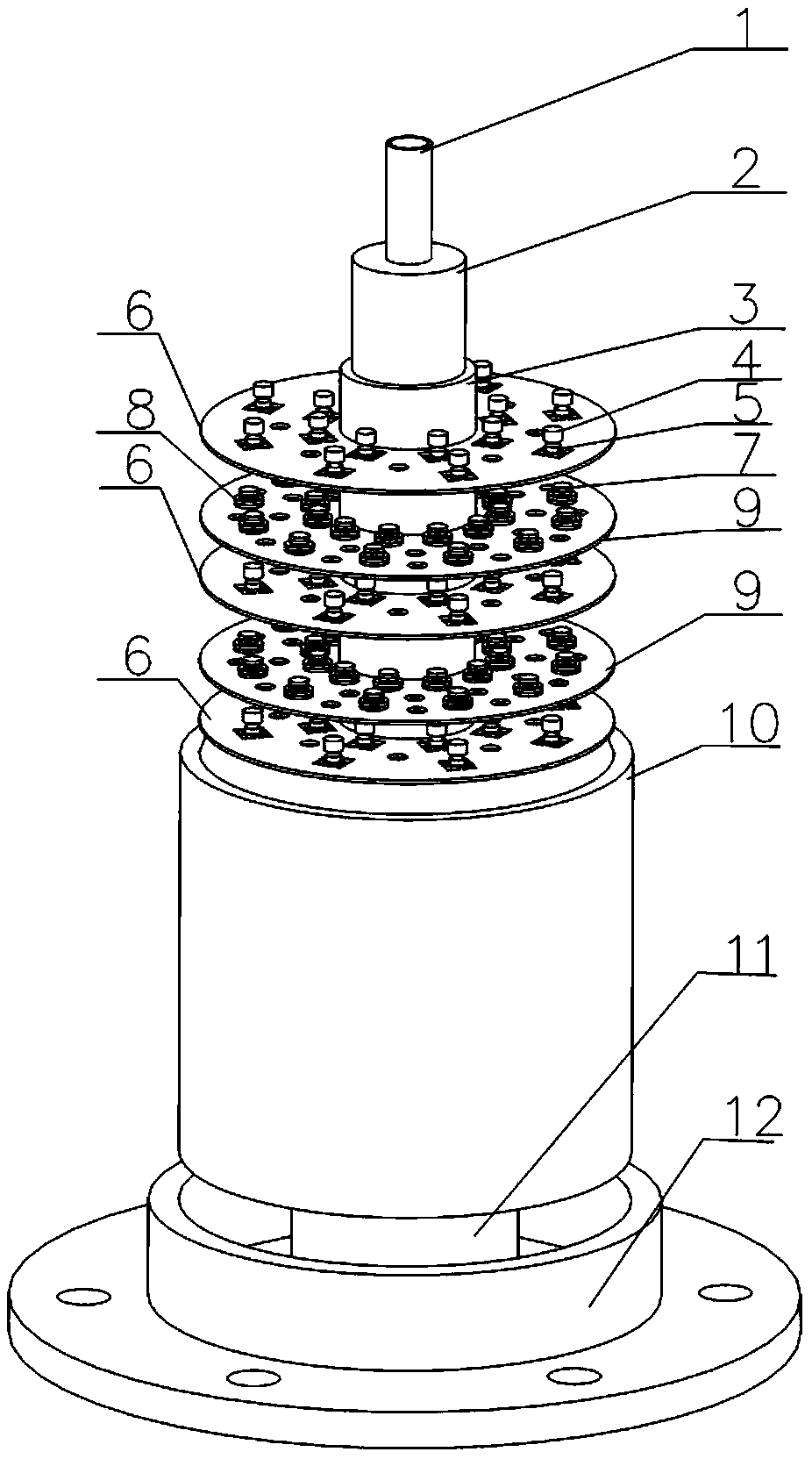

[0034] combine figure 1 and figure 2 Explain that a composite structure phononic crystal vibration isolation support of this embodiment is mainly composed of a vibration input bushing 1, a vibration isolation bushing 2, a support bushing 3, a surface type local resonance type vibration isolation component, an embedded local Consists of a resonance type vibration isolation assembly, an outer sleeve 10, a limiting structure 11 and a vibration isolator base 12;

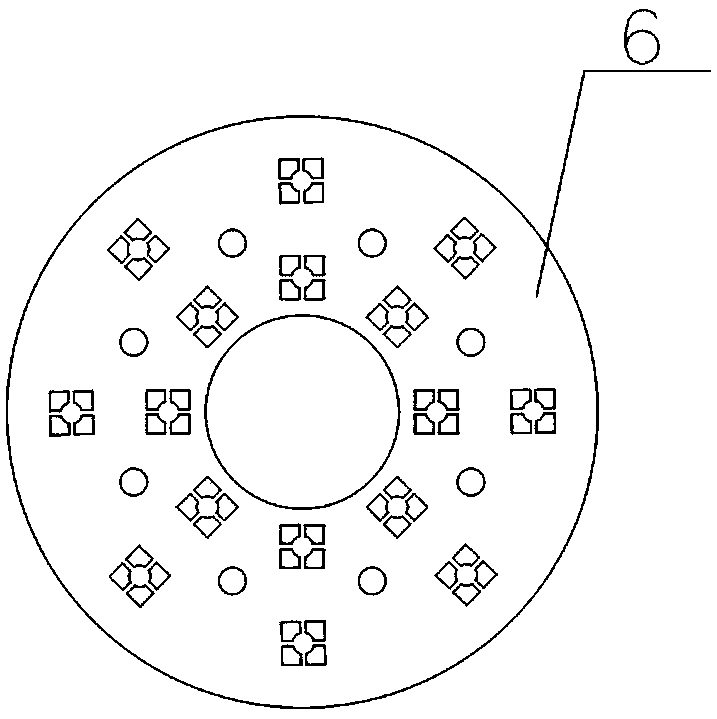

[0035] The surface-type local resonance type vibration isolation component is composed of multiple scatterers Ⅰ4, multiple elastic columns 5 and punched base plate Ⅰ6, and multiple elastic columns 5 are periodically fixed on the fixed piece on the punched base plate Ⅰ6. A scatterer I4 is periodically fixed on a plurality of elastic columns 5, and the number of the two is the same;

[0036] The embedded local resonance type vibration isolation component is composed of a plurality of scatterers II7, a plurality of elast...

Embodiment 2

[0040] combine figure 2 Explain that the vibration input bushing 1 of a composite structure phononic crystal vibration isolation support in this embodiment is inserted into the vibration isolation bushing 2, and the two are glued together, and the vibration isolation bushing 2 is inserted into the support bushing 3, and the two are glued together, the supporting bushing 3 is respectively inserted into the round hole in the middle of the surface local resonance type vibration isolation component and the embedded local resonance type vibration isolation component, and the outer surface of the supporting bushing 3 is respectively It is glued together with the inner surface of the central circular hole of the surface local resonance type vibration isolation component and the inner surface of the central circular hole of the embedded local resonance vibration isolation component, and the surface of the outer ring of the surface local resonance vibration isolation component, embedde...

Embodiment 3

[0042] combine figure 2 Note that the surface-type local resonance type vibration isolation components of a composite structure phononic crystal vibration isolation bearing in this embodiment are periodically arranged along the axial direction of the support bushing 3, and the embedded local resonance type vibration isolation components are arranged along the axis of the support bushing 3. The sleeve 3 is arranged periodically in the axial direction, and each layer of embedded local resonance type vibration isolation components is evenly spaced between two layers of surface type local resonance type vibration isolation components. Such setting increases the period number of the local resonant phononic crystal on the premise of ensuring the support rigidity, which is beneficial to increase the vibration isolation capacity of the composite structure vibration isolator. Moreover, by evenly distributing the embedded local resonance type vibration isolation components at intervals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com