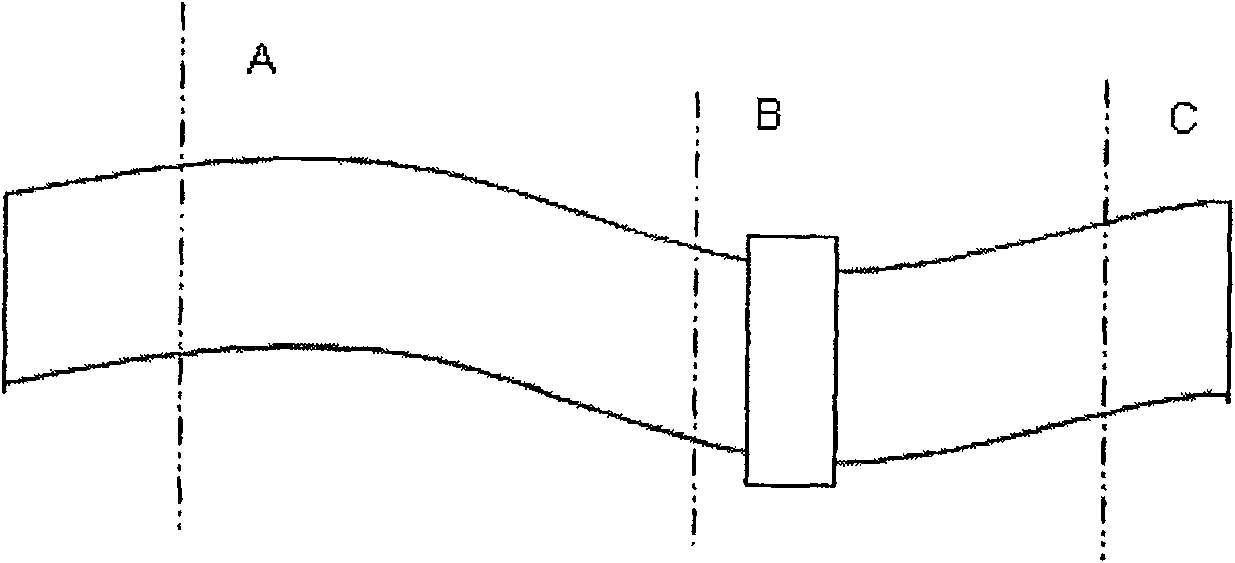

Design method for six-point suspension system of high-power diesel power assembly

A high-power diesel engine and powertrain technology, applied in the direction of power plant, jet propulsion device, internal combustion propulsion device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The design scheme of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments.

[0049] Taking the design of the WP10 diesel engine powertrain mount system as an example, the powertrain has a mass of 1.2 tons, an inline six-cylinder, a rated speed of 2200r / min, an idle speed of 600r / min, and a rated power of 243kW.

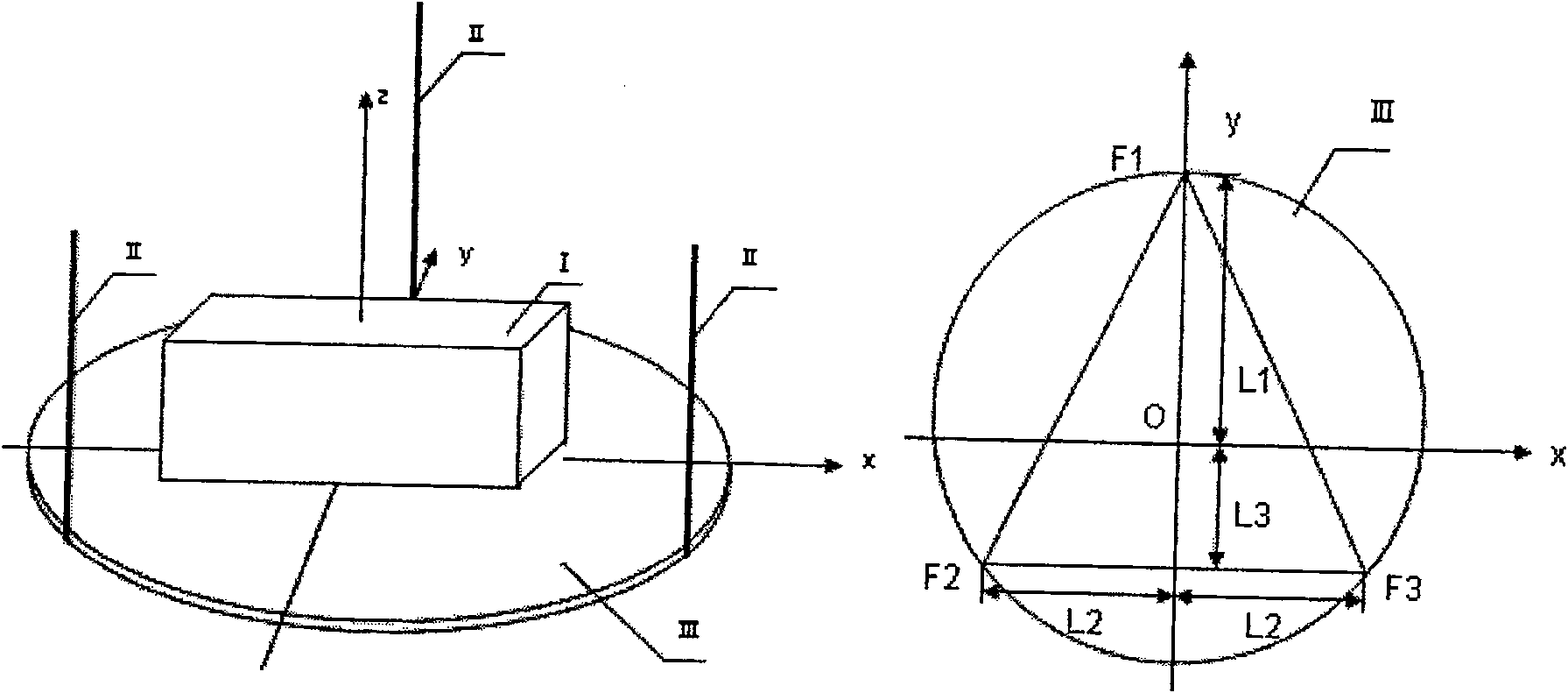

[0050] 1. Selection of the best suspension point.

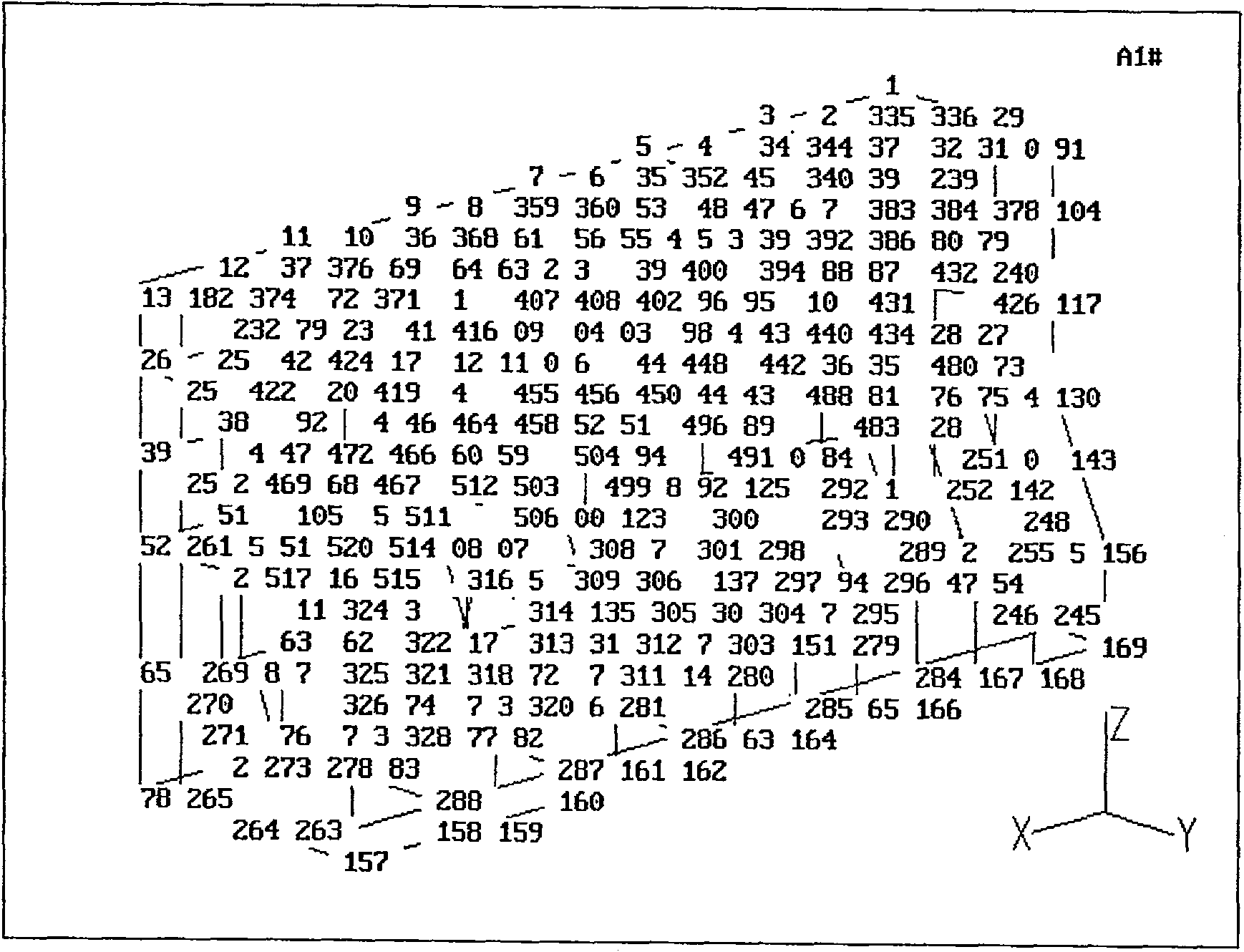

[0051] 1.1 Simplify the powertrain model and arrange measuring points. as attached figure 2 . And input the simplified powertrain geometry into the computer test system. In this embodiment, a total of 640 measuring points and 1920 response signals are arranged.

[0052]1.2 Suspend the powertrain I with a rope, select the measuring point numbered 1 as the excitation point, and measure the vibration response of other points. Repeat the sampling for each measuring point 3 times, and then average to eliminate the noise in the sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com