Self-separation type wet dust and gas separator of sweeper

A gas separator and self-separation technology, applied in separation methods, dispersed particle separation, cleaning methods, etc., can solve the problems of occupying the space on the sweeper, affecting the vacuuming effect, and small capacity of the dustbin, and achieving reliable operation and storage. The effect of large volume, reduced manufacturing cost and operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

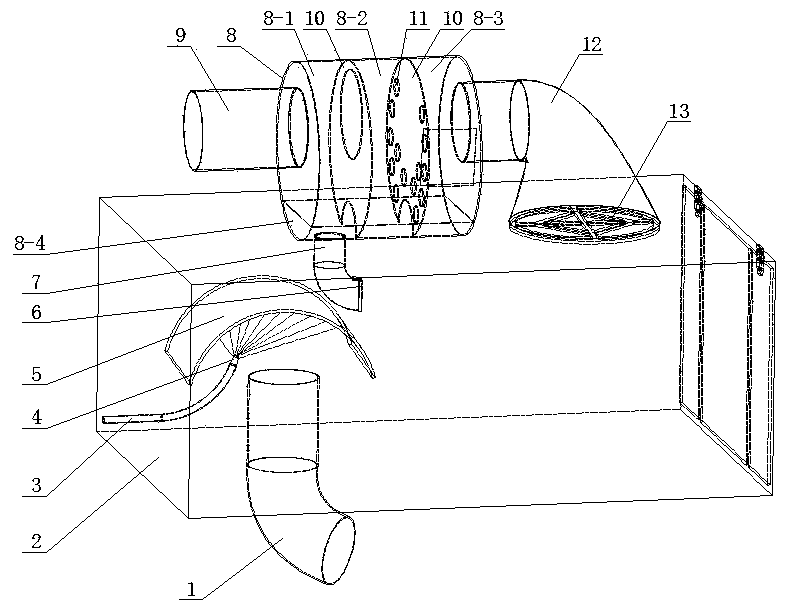

[0008] Such as figure 1 As shown, it is a self-separating wet dust gas separator for sweeping machines, which mainly includes a garbage bin 2, which is connected with an arc-shaped deflector 5, and a garbage diversion pipe 1 is placed on the garbage bin 2, and the garbage diversion pipe 1 The upper end of the upper end is arranged on the below of the arc deflector 5, and the dust suppression nozzle 3 is also worn on the dustbin 2, and one end of the dust suppression nozzle 3 is connected to the water spray nozzle 4, and the water spray nozzle 4 is arranged on the arc deflector 5. below. A separation box 8 is arranged above the dustbin 2, and the interior of the separation box 8 is provided with two filter plates 10 that divide the separation box into a primary filter 8-3, an intermediate filter chamber 8-2, and a fine filter chamber 8-1. Airflow vents 11 are respectively arranged on the plates 10, and the airflow vents 11 on the two filter plates 10 are arranged in a staggere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com