Automatic biomass fuel briquette production technology

A technology of biomass fuel and production process, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of insufficient output and shortage of human resources, and achieve the effect of improving production efficiency and output, reducing production cost and saving labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below with reference to the drawings and embodiments.

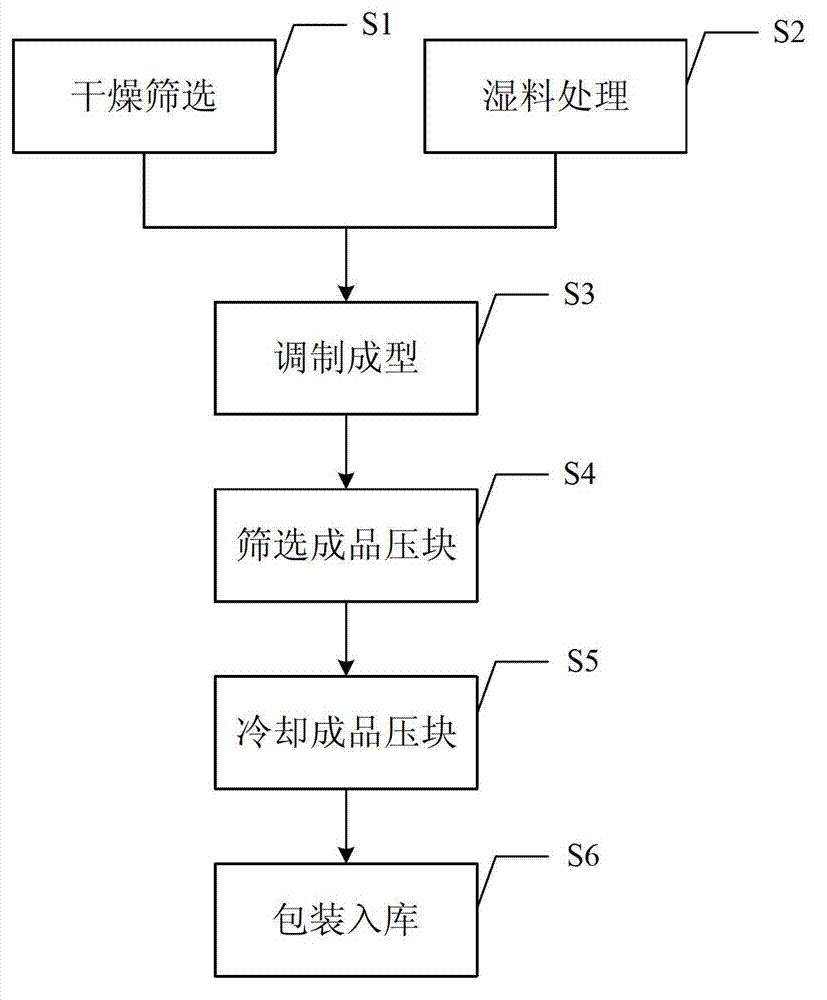

[0022] Such as figure 1 As shown, the present invention provides an automated production process for dense molding of biomass fuel, which includes the following steps:

[0023] Step S1, dry material screening: the dried material is screened by the drum screen a and then transported to the inclined loader.

[0024] Specifically, the biomass materials with suitable moisture are sent to the trommel a by the belt conveyor a for screening, the materials with larger particle size or impurities are removed, and they are directly sent to the inclined loader through the horizontal feeder.

[0025] Step S2: Wet material processing: the wet material is screened, dried and dust-removed and then becomes dry material, and then enters the next process, including the following steps:

[0026] (1) Wet material screening: the wet material is screened by the drum screen b and then tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com