Magnetic hydrophobic self-cleaning paint and preparation method thereof

A coating and hydrophobic technology, which is applied in the field of nano-materials, can solve problems such as inapplicability to steel surfaces, and achieve the effects of good coating contact angle, strong adhesion, and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

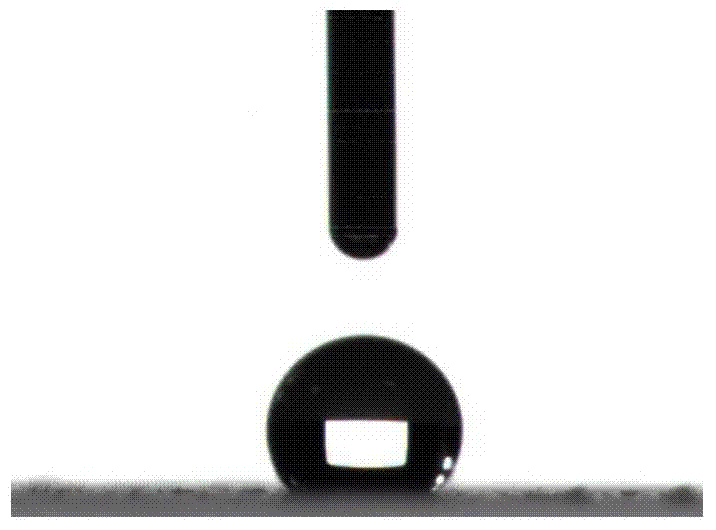

Image

Examples

Embodiment 1

[0028] Prepare the magnetic hydrophobic self-cleaning coating of the present invention according to the following proportions, in terms of weight fraction: 10 parts of isooctyltriethoxysilane, Fe modified by dendrimers 3 o 4 0.1 parts of magnetic nanoparticles, 89.9 parts of absolute ethanol.

[0029] The preparation process is as follows:

[0030] Preparation of Fe3O4 magnetic nanoparticles by co-precipitation method; Fe 2+ with Fe 3+ The ions were mixed according to the ratio of 1:2, and then under the protection of nitrogen, a NaOH solution with a concentration of 4M was added, and the reaction was carried out at 80°C for 60min to obtain Fe 3 o 4 Magnetic nanoparticles were washed three times with ultrapure water and absolute ethanol, and set aside.

[0031] Aminosilane modified Fe 3 o 4 Magnetic nanoparticles: 5% Fe 3 o 4 Magnetic nanoparticles were dissolved in a certain amount of ethanol solution, ultrasonically mixed for 30 minutes to make it evenly mixed, then...

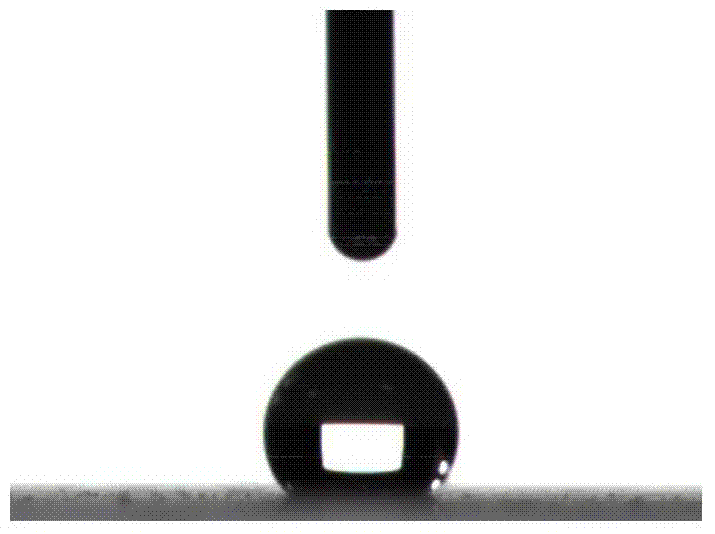

Embodiment 2

[0037] Prepare the magnetic hydrophobic self-cleaning coating of the present invention according to the following proportions, in terms of weight fraction: 25 parts of isooctyltriethoxysilane, Fe modified by dendrimers 3 o 4 0.25 parts of magnetic nanoparticles, 74.75 parts of absolute ethanol.

[0038] The preparation process is as follows:

[0039] Preparation of Fe by co-precipitation method 3 o 4 Magnetic nanoparticles; Fe 2+ with Fe 3+ The ions were mixed according to the ratio of 1:2, and then under the protection of nitrogen, a NaOH solution with a concentration of 4M was added, and the reaction was carried out at 80°C for 60min to obtain Fe 3 o 4 Magnetic nanoparticles were washed three times with ultrapure water and absolute ethanol, and set aside.

[0040] Aminosilane modified Fe 3 o 4 Magnetic nanoparticles: 5% Fe 3 o 4 Magnetic nanoparticles were dissolved in a certain amount of ethanol solution, ultrasonically mixed for 30 minutes to make it evenly mixe...

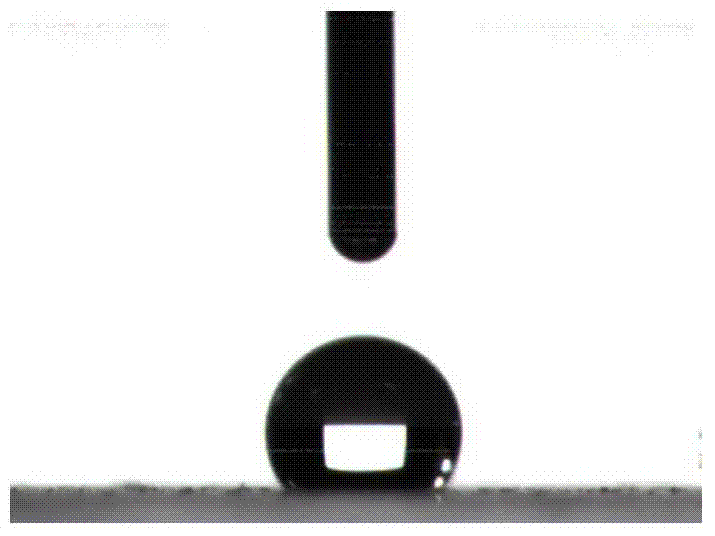

Embodiment 3

[0046] Prepare the magnetic hydrophobic self-cleaning coating of the present invention according to the following proportions, in terms of weight fraction: 50 parts of isobutyltriethoxysilane, Fe modified by dendrimers 3 o 4 0.5 parts of magnetic nanoparticles, 49.5 parts of absolute ethanol.

[0047] The preparation process is as follows:

[0048] Preparation of Fe by co-precipitation method 3 o 4 Magnetic nanoparticles; Fe 2+ with Fe 3+ The ions were mixed according to the ratio of 1:2, and then under the protection of nitrogen, a NaOH solution with a concentration of 4M was added, and the reaction was carried out at 80°C for 60min to obtain Fe 3 o 4 Magnetic nanoparticles were washed three times with ultrapure water and absolute ethanol, and set aside.

[0049] Aminosilane modified Fe 3 o 4 Magnetic nanoparticles: 5% Fe 3 o 4 Magnetic nanoparticles were dissolved in a certain amount of ethanol solution, ultrasonically mixed for 30 minutes to make it evenly mixed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com