Preparation method for titanium dioxide pigment

A titanium dioxide and pigment technology, which is applied in the field of preparing titanium dioxide pigments for laminated paper with high light resistance, can solve the problems of yellowing of titanium dioxide pink and increase production costs, and achieves improvement of light resistance and weather resistance, changes in surface charge characteristics, The effect of improving water dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of the titanium dioxide pigment according to the exemplary embodiment of the present invention comprises the following steps:

[0023] (1) After the titanium dioxide powder is beaten to obtain a titanium dioxide slurry with a concentration of 250-350g / L, disperse it with a phosphate-containing compound, and adjust the pH value of the slurry to 9.0-11.0 with deionized water and dilute alkali solution. Wherein, the titanium dioxide powder comes from the sulfuric acid titanium dioxide production process, and the rutile conversion rate of the titanium dioxide powder is above 98%.

[0024] (2) Heat the slurry to 80-100°C, add sodium silicate solution, the amount of sodium silicate solution is based on SiO 2 Calculated as TiO in the slurry 2 1.0-5.0% of the mass, keep the system temperature unchanged after adding the sodium silicate solution. Wherein, if the temperature is too low or too high, no dense silicon coating can be obtained.

[0025] (3) Ad...

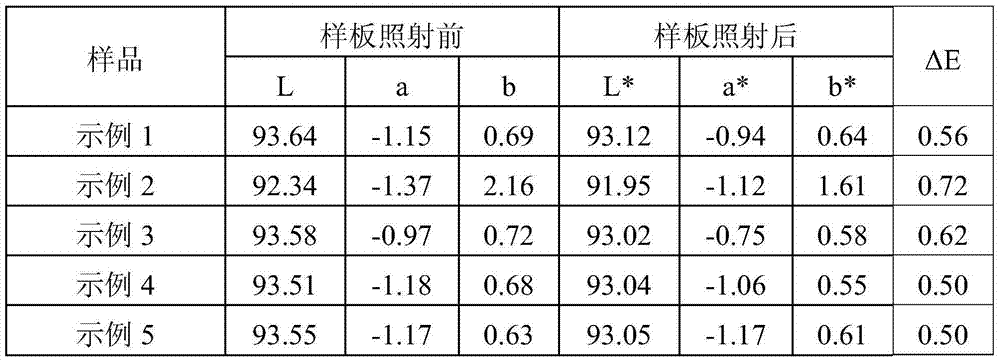

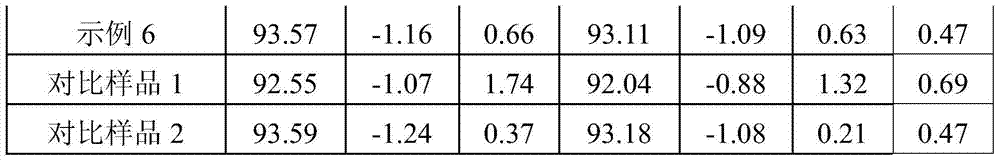

example 1

[0041] (1) After the titanium dioxide powder is beaten to obtain a titanium dioxide slurry with a concentration of 250g / L, it is dispersed with sodium hexametaphosphate, and the pH value of the slurry is adjusted to 9.0 with a dilute alkali solution. Among them, the rutile conversion of the titanium dioxide powder 98.5%

[0042] (2) Heat the slurry to 80°C, add sodium silicate solution, the amount of sodium silicate solution is based on SiO 2 Calculated as TiO in the slurry 2 1.5% of the mass, keep the temperature of the system constant after adding the sodium silicate solution.

[0043] (3) Add dilute acid to adjust the pH value of the slurry to 3.0, and mature for 60 minutes.

[0044] (4) Add dilute alkali solution to adjust the pH value of the slurry to 7.0.

[0045] (5) Add phosphoric acid solution, and add sodium metaaluminate solution to maintain the pH value of the slurry at 8.0. Among them, the addition amount of phosphoric acid solution is P 2 o 5 Calculated as ...

example 2

[0051] (1) After the titanium dioxide powder is beaten, a titanium dioxide slurry with a concentration of 350g / L is obtained, which is dispersed with sodium hexametaphosphate, and the pH value of the slurry is adjusted to 11.0 with a dilute alkali solution. Wherein, the rutile conversion rate of the powder is 99.0%.

[0052] (2) Heat the slurry to 100°C, add sodium silicate solution, the amount of sodium silicate solution is based on SiO 2 Calculated as TiO in the slurry 2 3.0% of the mass, keep the system temperature constant after adding the sodium silicate solution.

[0053] (3) Add dilute acid to adjust the pH value of the slurry to 5.0, and ripen for 30 minutes.

[0054] (4) Add dilute alkali solution to adjust the pH value of the slurry to 9.0.

[0055] (5) Add phosphoric acid solution, and then add potassium metaaluminate solution to maintain the pH value of the slurry at 9.0. Among them, the addition amount of phosphoric acid solution is P 2 o 5 Calculated as TiO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com