Method for extracting pure ethylene-ethylene vinyl-acetate copolymer

A technology of vinyl acetate and copolymers, which is applied in the field of rapid extraction of pure ethylene-vinyl acetate copolymers, can solve the problems of low purity of ethylene vinyl acetate copolymers and the qualitative influence of ethylene vinyl acetate copolymers, and achieve qualitative results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Get about 1g of component 1# after mixing,

[0053] Dissolve 1# in the first solvent, partially dissolve the hot melt adhesive in methyl acetate, and separate to obtain insoluble matter;

[0054] Heating and dissolving the insoluble matter in petroleum ether, dissolving part of the insoluble matter in petroleum ether, and separating to obtain a solution;

[0055] drying the obtained solution to obtain the sample to be tested;

[0056] Add the sample to be tested into a beaker filled with chloroform;

[0057] Heat to dissolve the sample to be tested completely;

[0058] Cool at room temperature and place it in a fume hood to volatilize naturally. With the volatilization of the solvent, a precipitate will adhere to the wall of the beaker, and the precipitate is pure ethylene-vinyl acetate copolymer.

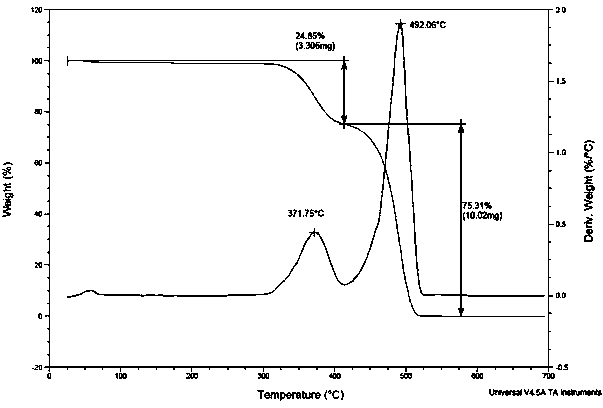

[0059] Send TGA to detect precipitates. The obtained TGA spectrum is shown in figure 1 , by calculating VA%=35.6%, the actual VA content of EVA 28420 is 35%.

[0060]...

Embodiment 2

[0062] Get about 1g of component 2# after mixing,

[0063] Dissolve 1# in the first solvent, partially dissolve the hot melt adhesive in butyl acetate, and separate to obtain insoluble matter;

[0064] The insoluble matter is heated and dissolved in ethanol, the insoluble matter is partially dissolved in ethanol, and the solution is obtained by separation;

[0065] drying the obtained solution to obtain the sample to be tested;

[0066] Add the sample to be tested into a beaker filled with xylene;

[0067] Heat to dissolve the sample to be tested completely;

[0068] Cool at room temperature and place it in a fume hood to volatilize naturally. With the volatilization of the solvent, a precipitate will adhere to the wall of the beaker, and the precipitate is pure ethylene-vinyl acetate copolymer.

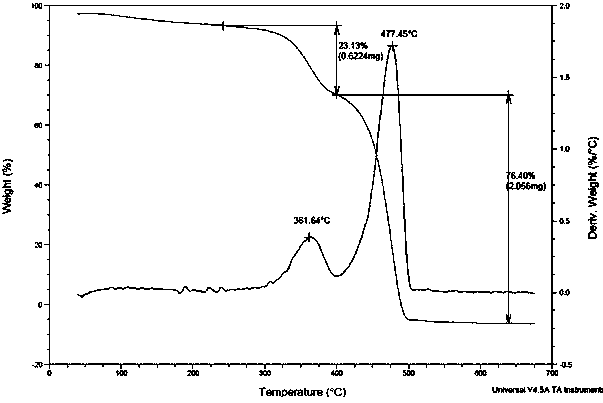

[0069] Send TGA to detect precipitates. The obtained TGA spectrum is shown in figure 2 , VA%=33.1% is obtained through calculation, and the actual VA content of EVA 28150 is 35...

Embodiment 3

[0072] Get about 1g of component 3# after mixing,

[0073] Add the sample to be tested into a beaker filled with toluene;

[0074] Heat to dissolve the sample to be tested completely;

[0075] Cool at room temperature and place it in a fume hood to volatilize naturally. With the volatilization of the solvent, a precipitate will adhere to the wall of the beaker, and the precipitate is pure ethylene-vinyl acetate copolymer.

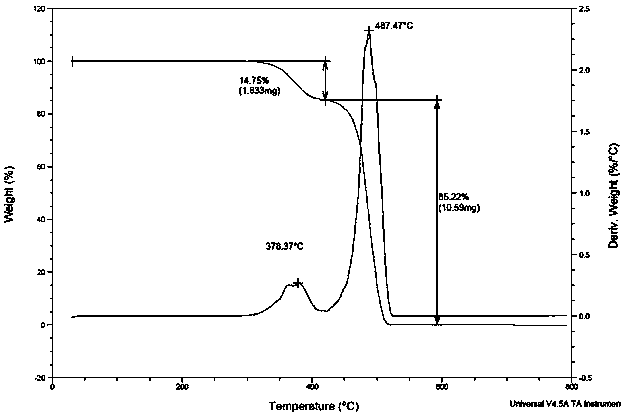

[0076] Send TGA to detect precipitates. The obtained TGA spectrum is shown in image 3, VA%=21.1% is obtained through calculation, and the actual VA content of EVA V5110J is 20%.

[0077]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com