Supercritical water oxidation reaction apparatus and method

A supercritical water oxidation and reaction device technology, which is applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of prolonged reaction time, large heat consumption, and lower temperature of the reaction zone, so as to reduce requirements and manufacturing difficulties, and reduce equipment manufacturing costs , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

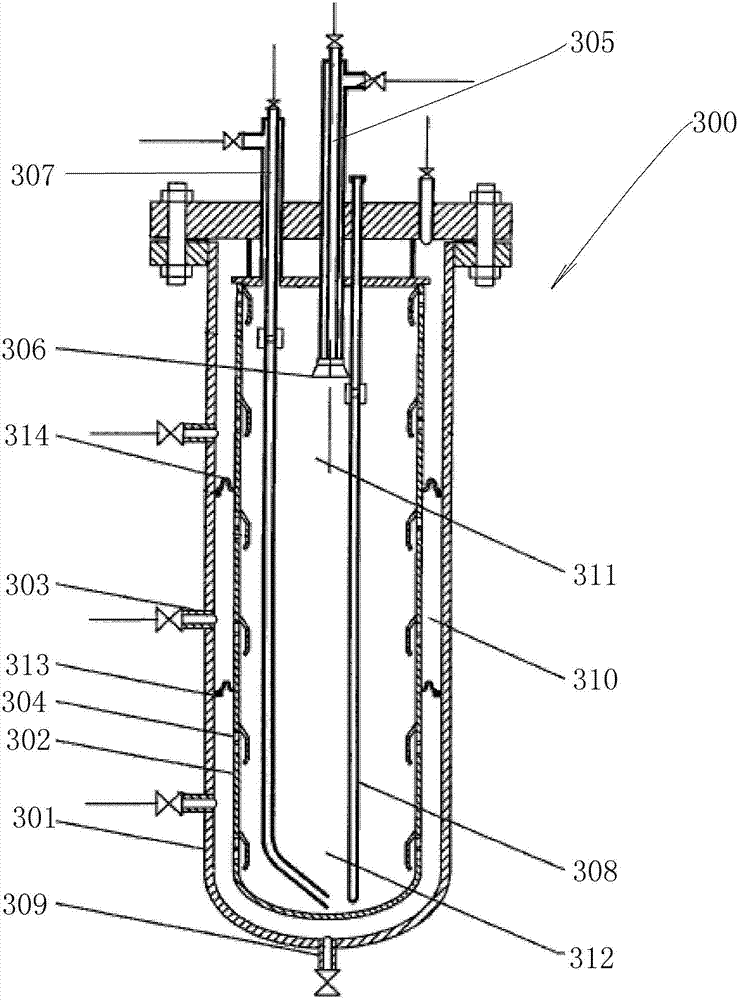

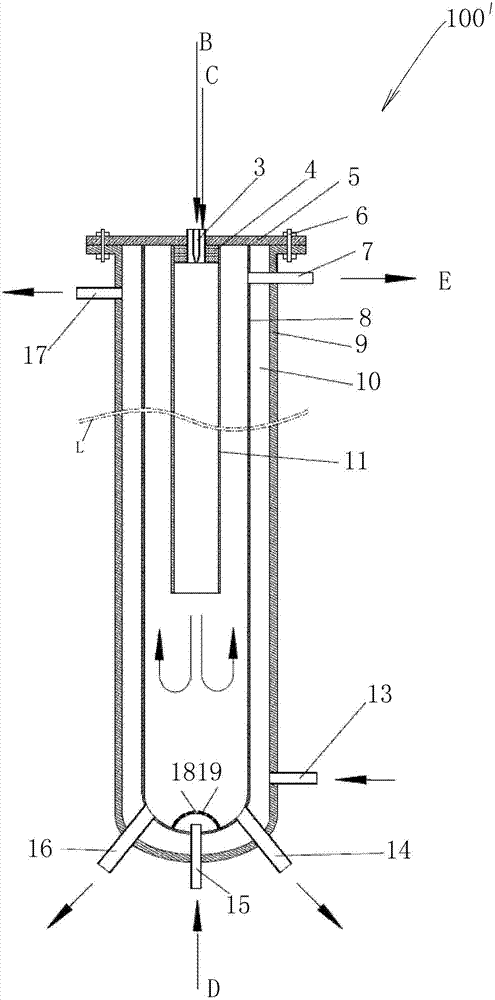

[0050] Use the sludge slurry with a concentration of 5% as the original reaction raw material, and preheat it to about 280°C to form the raw material A to be preheated, enter the raw material A to be preheated from the material input pipe 2 into the heat exchange coil, and use The reaction heat released by the oxidation reaction in the reaction zone of the inner casing is preheated. After preheating, the temperature of the material reaches about 480 ° C. The reaction raw material B is discharged from the raw material output pipe 1 and then transported to the reactant nozzle 3 . Afterwards, reaction raw material B and oxidizing agent C (for example, the oxygen of normal temperature, oxidizing agent consumption is 110% of COD content in the raw material) enter the reaction zone of inner housing 8 respectively from the central tube of reactant nozzle 3 and annular structure, wherein reaction raw material B is mixed with oxygen to carry out supercritical water oxidation reaction, t...

Embodiment 2

[0054] Use coal-water slurry with a concentration of 10% as the original reaction raw material, and preheat it to about 300°C to form the raw material A to be preheated, enter the raw material A to be preheated from the material input pipe 2 into the heat exchange coil, and use The reaction heat released by the oxidation reaction in the reaction zone of the inner casing 8 is preheated. After preheating, the temperature of the material reaches about 500°C. Afterwards, reaction raw material B (coal-water slurry) and oxidant C (for example, the oxygen that preheats to about 80 ℃, the oxidant consumption is 10% of COD content in the raw material) enters from the center tube of reactant nozzle 3 and the annular structure respectively. In the reaction zone of the shell 8, the reaction raw material B is mixed with oxygen to perform supercritical water oxidation reaction, the reaction temperature is about 663° C., and the pressure is 25-26.3 MPa. The high-temperature reaction product ...

Embodiment 3

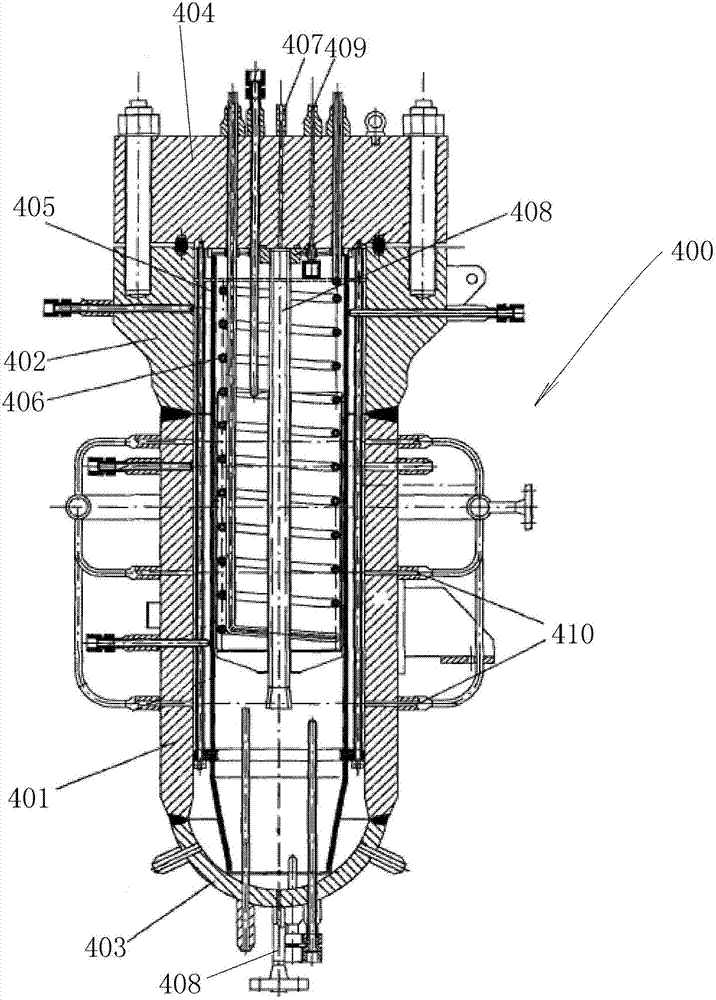

[0058] Such as Figure 4 As shown, using waste water with a COD content of about 32500mg / L and an ammonia nitrogen content of about 120mg / L as the original reaction raw material, and preheating to about 350°C to form the raw material A to be preheated, the preheated Raw material A is delivered to reactant nozzle 3 . Afterwards, the raw material A and oxygen to be preheated enter the reaction zone of the inner housing 8 from the central tube and the annular structure of the reactant nozzle 3 respectively, wherein the reaction raw material B is mixed with oxygen to carry out supercritical water oxidation reaction, and the reaction temperature is about 530°C, the pressure is 28-30MPa.

[0059] In this example 3, supercritical water with a temperature of about 385° C. and a pressure of about 28.5-32 MPa is used as the bubbling medium D to enter the interior of the inner shell 8 from the bubbling medium delivery pipe 15 and pass through the dispersion holes 18 on the shield 19 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com