Fan pneumatic conveying and cleaning and settling system

A technology of pneumatic conveying and fan, applied in the direction of conveyor, transportation and packaging, conveying bulk materials, etc., can solve the problems of impeller blade wear, reduce the service life of fan, complex process, achieve small size and improve normal operation efficiency , the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

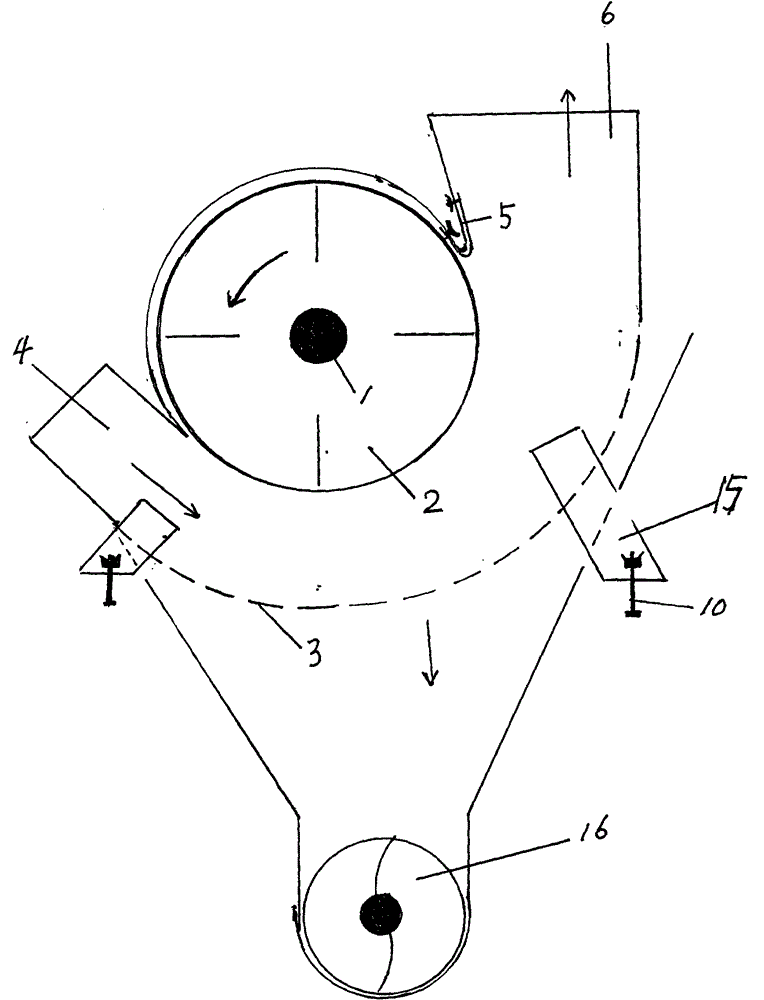

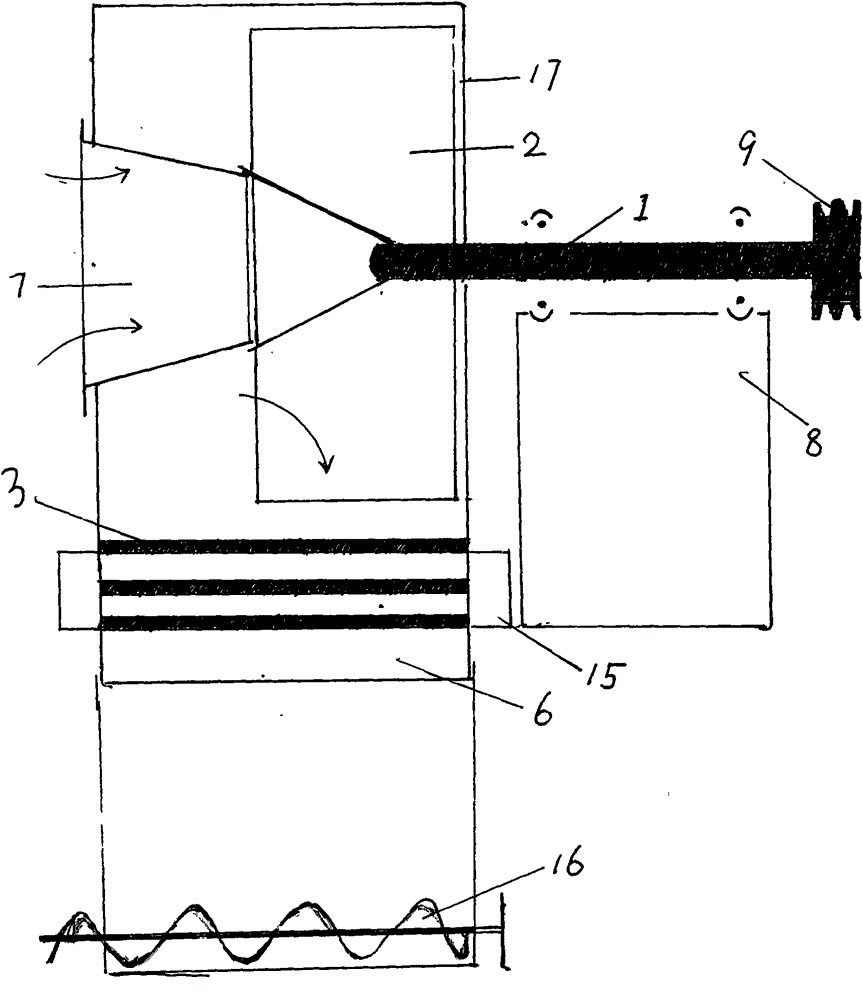

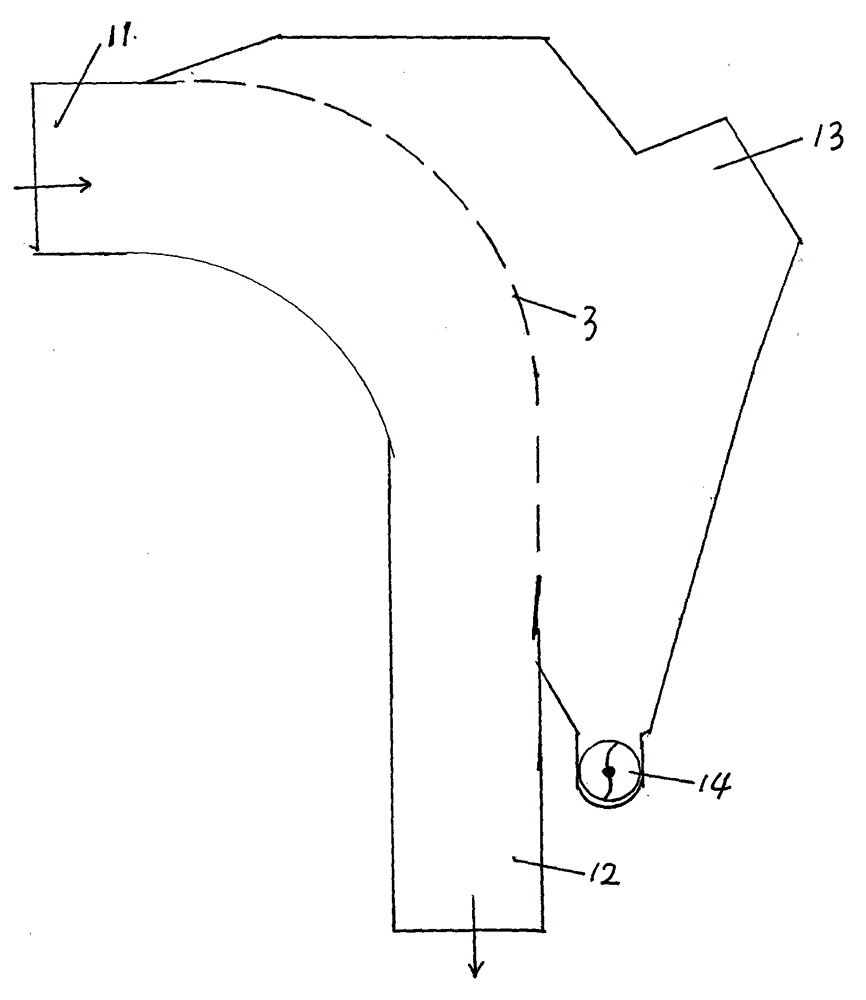

[0033] In order to make the purpose of the present invention, technical solutions and advantages more clearly understood, the present invention will be further described in detail below in conjunction with the accompanying drawings

[0034] The ventilator pneumatic conveying and cleaning and settling system of the present invention changes the structure of the existing ventilator, and sets a radial air inlet (material) port at an appropriate position of the casing, cleans the combination (or seals the arc-shaped plate), and installs a miscellaneous discharge at its lower part The auger, set the air tongue and its adjusting plate at the position of the fan air tongue, set the cleaning combination (or sealing arc plate) in the settlement part, the suction port of the dust exhaust pipe, the miscellaneous auger, etc., and use the impeller to drive Next, the negative pressure generated at the radial air inlet (material) port, the positive pressure generated at the cleaning combinati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com