Sandwich type bicycle rim and manufacturing method thereof

A bicycle, sandwich-type technology, applied to rims, vehicle parts, transportation and packaging, etc., can solve problems such as insufficient bonding force and different thermal expansion coefficients, and achieve the effects of increasing weight, improving safety, and improving brake heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

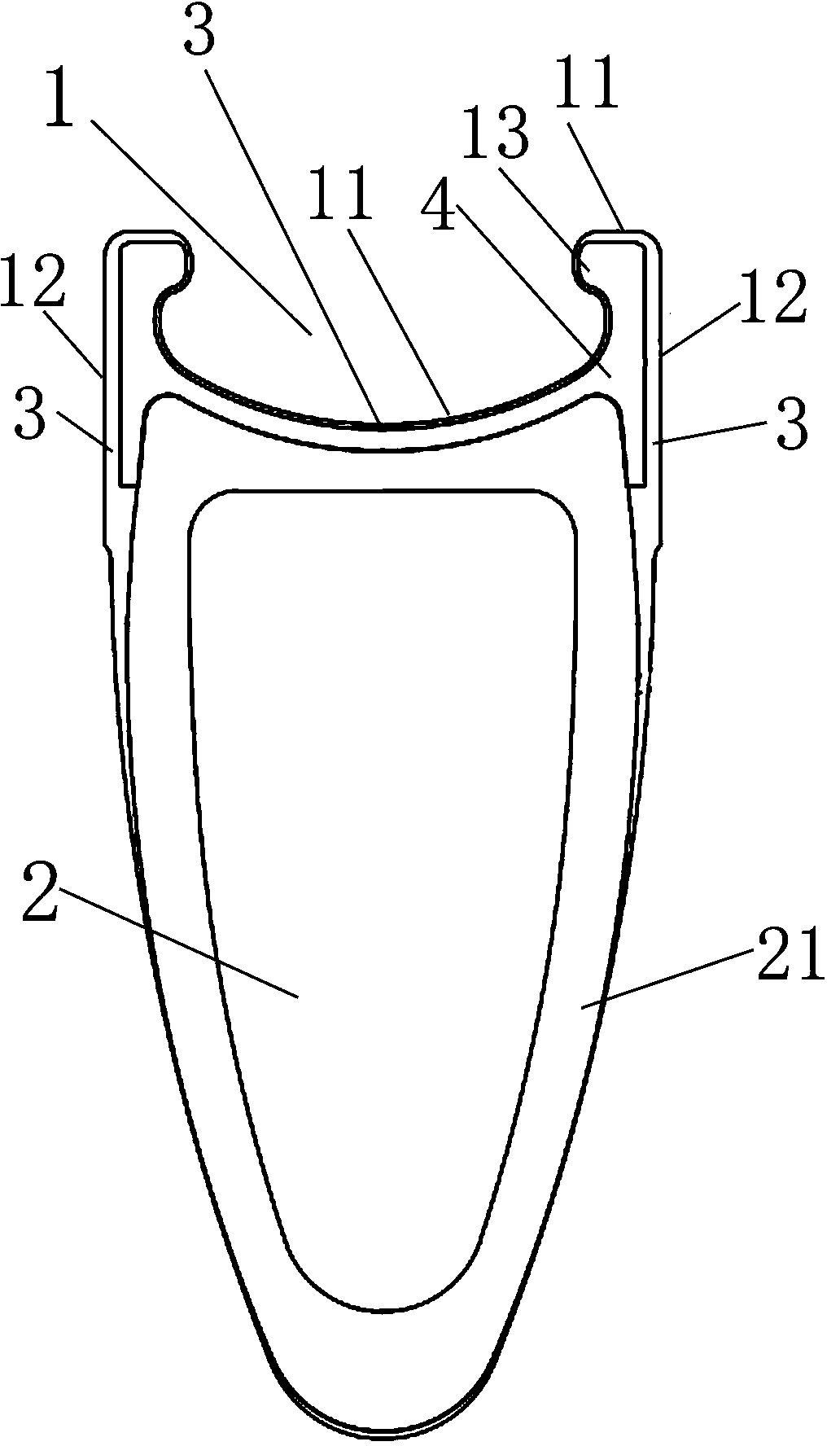

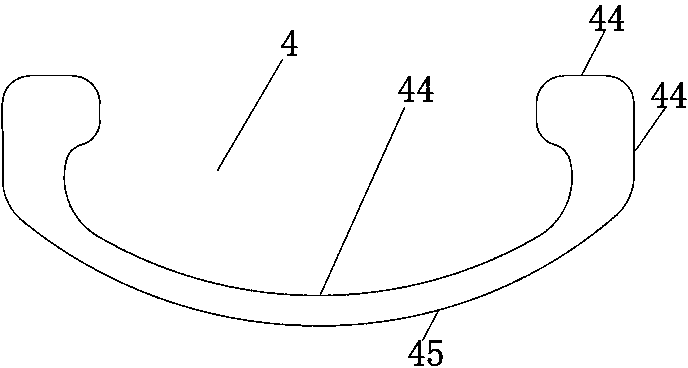

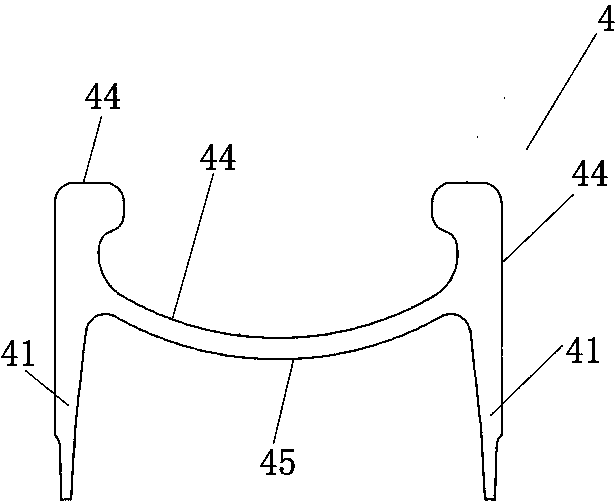

[0033] Such as figure 1 As shown, a sandwich type bicycle rim provided by the present invention includes a tire position hole 1 and a closed chamber 2, which are arranged up and down. 12. The fetal position hole 1 contains at least one metal alloy layer 4, the outer surface 11 of the fetal position hole 1 and the braking surface 12 each have a layer of carbon fiber layer 3, and the metal alloy layer 4 is wrapped in it to form a sandwich body; the fetal position hole The outer surface 11 of 1 and the carbon fiber layer 3 of the braking surface 12 are integrally formed with the wall body 21 of the chamber 2 with carbon fiber material. The upper part in the tire position hole groove 1 is provided with a hook 13 for blocking the inner tube. The alloy density of the metal alloy layer 4 is lower than 2.8 g / cm 3 , the metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com