Multi-tg carbon fiber rim and preparation method thereof

A technology of carbon fiber and carbon fiber materials, applied in the direction of wheels, rims, wheels made of non-metallic materials, etc., can solve the problems of low impact resistance, low output, and restrictions on large-scale promotion, achieve good rigidity and toughness, and improve impact resistance strength and reduce the risk of burning the frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

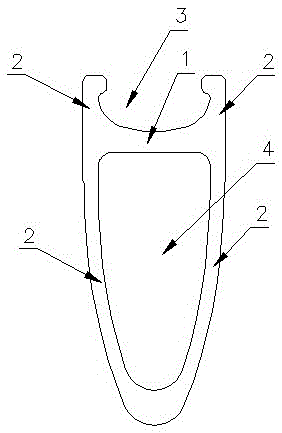

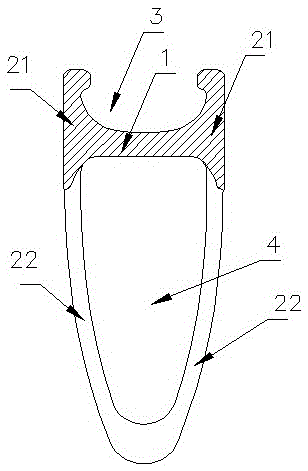

[0039] Such as figure 2 As shown, since the temperature of the braking edge 21 can reach above 180°C in the case of continuous braking on a long downhill slope, the epoxy resin carbon fiber material TG used in the "H" shape structure is required to be above 190°C; at the same time, considering the TG The higher the value, the more expensive the cost, and the poorer the interlayer bonding strength and impact resistance. The TG value of the epoxy resin carbon fiber material is best controlled below 220°C. The epoxy resin carbon fiber material used for the side wall 22 corresponding to the inner cavity 4 has a TG range of 100°C to 180°C. Considering the price and impact resistance, it is most preferable that the TG of the epoxy resin carbon fiber material used for the two side walls 22 corresponding to the inner cavity is 120°C.

Embodiment 2

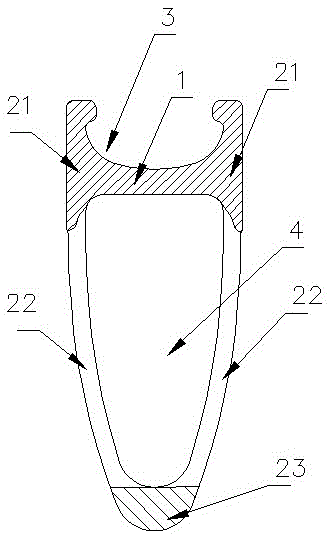

[0041] Such as image 3 As shown, the "H" shaped structure is the same as the first embodiment, the difference is that the TG value of the epoxy resin carbon fiber material used at the intersection 23 of the two side walls corresponding to the inner cavity is from 100°C to 130°C; The TG range of the epoxy resin carbon fiber material used for the remaining side walls corresponding to the body 4 is 150°C to 180°C.

[0042] The preparation method of embodiment one, comprises the following steps:

[0043] Step 1. Forming of "H"-shaped structure carbon ring: Make a forming mold 5 of "H"-shaped groove, and lay carbon fiber resin prepreg cloth with a TG range of 190°C to 220°C in the "H"-shaped groove of the mold 53, lock the mold and put it into a high-temperature oven for molding. The molding temperature in the oven is 200°C, and the heating time is 6 hours, or the molding temperature in the oven is 220°C, and the heating time is 4 hours; then demould and set aside ;

[0044] St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com