Detecting and sorting method for assembled lithium ion power batteries

A power battery and post-assembly technology, which is applied in the field of detection and sorting of lithium-ion power batteries after assembly, can solve the problems of manual sorting that cannot be accurately distinguished, cannot determine the cause of failure, and affects the handling of defective products, and achieves reliable and reliable performance. High performance and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In the following, the substantive features and advantages of the present invention will be further explained with examples, but the present invention is not limited to the listed embodiments.

[0021] The present invention is based on the existing lithium-ion battery assembly testing equipment. The assembly testing equipment has a touch screen device and a PLC controller. The battery assembly, testing and defective products are discharged through the control of the touch screen and the PLC controller.

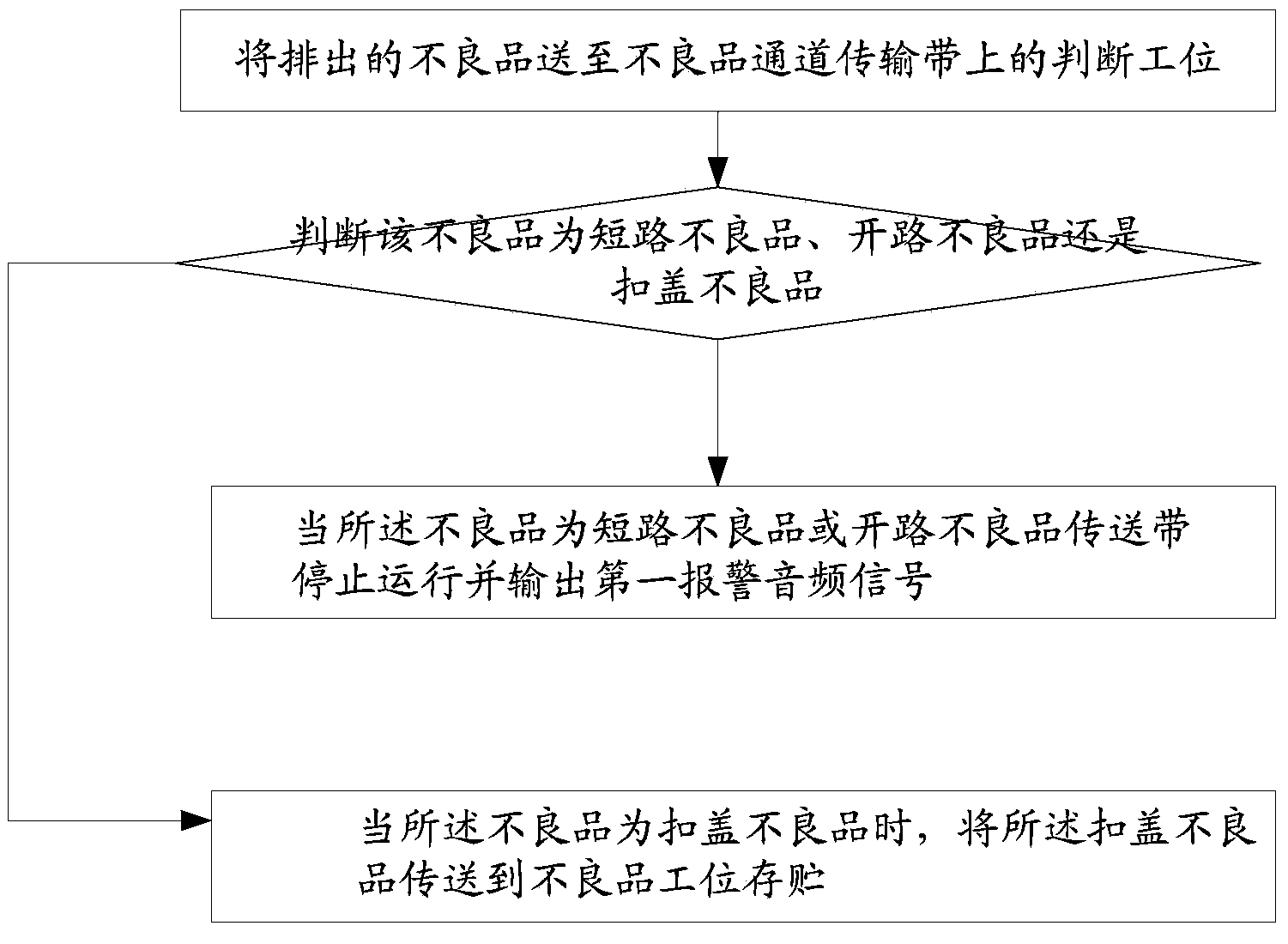

[0022] The present invention analyzes the defective products at each station of the defective product channel discharged through detection, and controls the equipment to execute corresponding actions according to the analysis situation to realize the sorting of different defective products.

[0023] The detection and sorting method of the lithium-ion power battery after assembly of the present invention includes the following steps:

[0024] When the defective product discharged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com