Special bucket tooth of high-frequency crushing hammer

A breaking hammer, high frequency technology, applied in grain processing and other directions, can solve the problems of excessive wear, small size, and low volume capacity of wear-resistant metal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the utility invention is described in further detail:

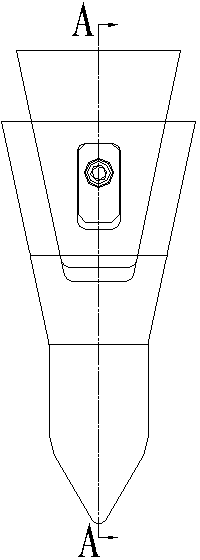

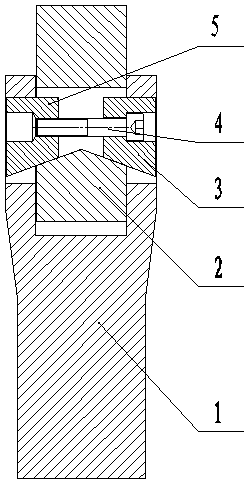

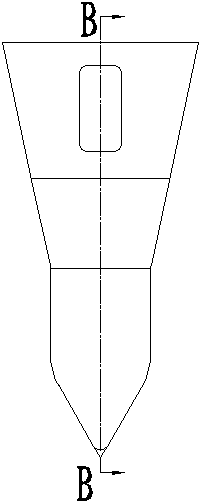

[0025] From figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 It can be seen that the special bucket tooth of the high-frequency breaker in the present invention is mainly composed of a tooth sleeve 1, a tooth root 2, and a gap adjustment mechanism; It is fixed on the dedendum 2 by a gap adjustment mechanism.

[0026] Among them, the cross-section of the front part of the gear sleeve 1 is rectangular, and compared with the excavator bucket teeth of the same width, its size in the thickness direction is larger, and the inner hole at the rear of the gear sleeve 1 is a symmetrical rectangular cross-section wedge-shaped hole , both sides of the inner hole are provided with square holes; the tooth root 2 is symmetrically wedge-shaped, and a wedge-shaped through hole is provided from the front and rear sides to the middle, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com