ALMN composite pillared clay-supported CRCE catalyst, preparation method and application

A composite column and catalyst technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of large solvent usage, unstable results, complicated processes, etc., and achieve large pore size, catalytic activity and stability, High catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

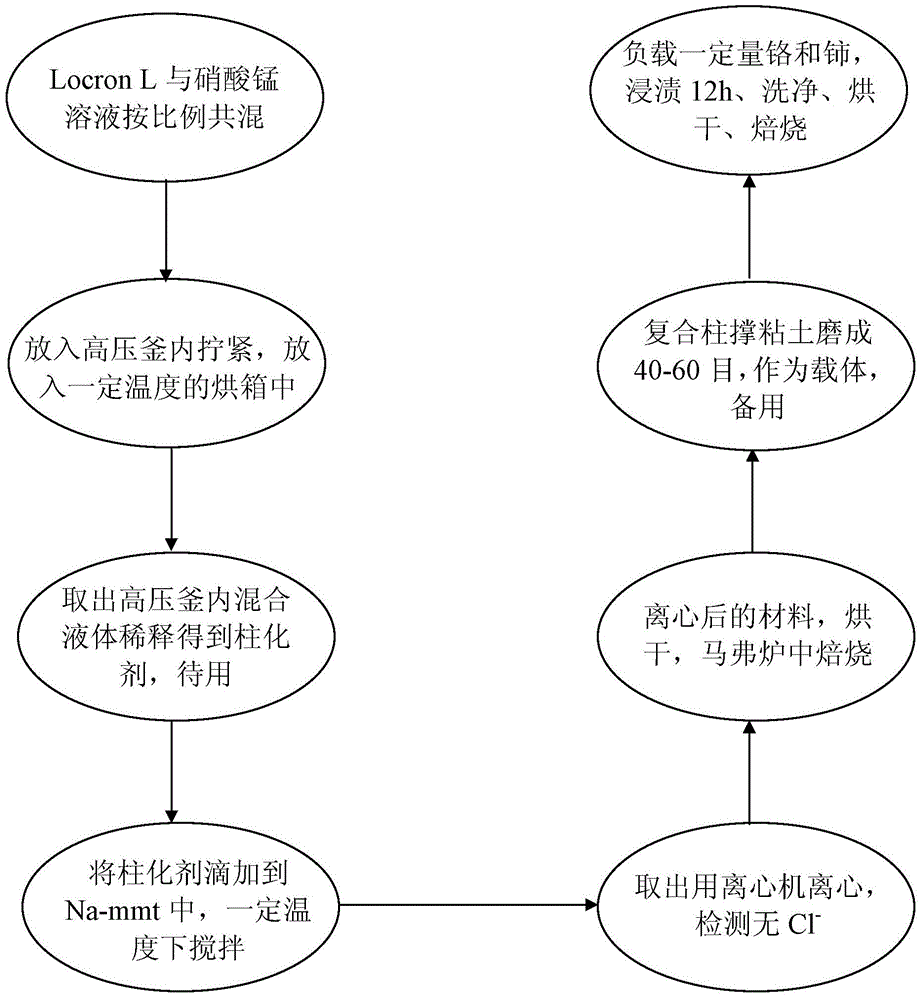

[0022] figure 1 A brief flow chart of the preparation process of the AlMn composite pillared clay-supported CrCe catalyst provided by the present invention. Combine below figure 1 And embodiment will further illustrate the present invention.

[0023]Preparation of AlMn composite columnizer: a. Take 10mL6mol / L Locron L and a certain volume of 1.0mol / L manganese nitrate solution with a pipette (adjust the molar ratio: Al / Mn=2.5 / 1, 5 / 1 , 7.5 / 1 or 10 / 1), add it to the autoclave, and then add deionized water to the autoclave to dilute the solution so that the concentration of Al ions is 2.5mol / L. In this example, Clariant Locron L basic aluminum chloride (liquid), also known as antiperspirant, was used as the source of the aluminum pillaring agent.

[0024] b. Tighten the lid of the autoclave with a wrench, put it in an oven at a certain temperature (80°C, 100°C or 120°C) and bake for 24 hours, take it out the next day, put the autoclave into cold water to cool, and wait until i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com