A flexible treatment system for residual cigarettes

A processing system and flexible technology, applied in tobacco, cigarette manufacturing, application, etc., can solve the problems of reducing the whole shred rate and yield of shredded tobacco, waste of shredded tobacco, and increase of shredded shreds, so as to improve the recycling rate and purity , Improve the purity of shredded tobacco and reduce the effect of crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

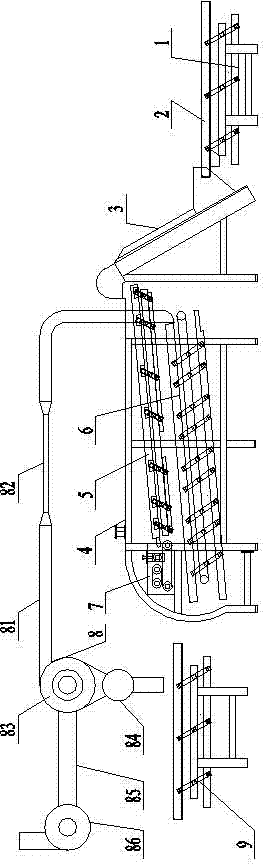

[0019] Such as Figure 1 to Figure 5 The shown flexible processing system for residual cigarettes includes a frame 4 and a carding and thinning vibrating trough 5 arranged on the frame 4, and a flexible kneading and tearing mechanism 7 is arranged at the discharge end of the carding and thinning vibrating trough 5. 5 and the bottom of the flexible kneading and tearing mechanism 7 is provided with a primary screening vibrating screen 6; adjacent to the rear of the frame 4 is an elevator 3 and a feeding vibrator 1, the material channel 36 of the elevator 3 and the carding and thinning vibrating groove 5 Corresponding to the receiving end. One side of the frame 4 is provided with a wind separation mechanism 8 corresponding to the primary screening vibrating screen 6 , and a secondary screening vibrating screen 9 is provided below the wind separation mechanism 8 .

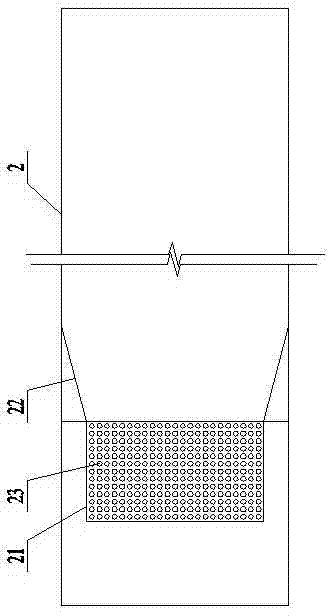

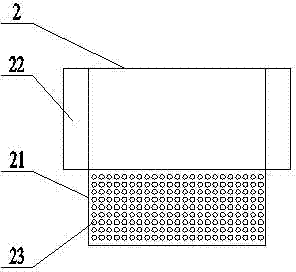

[0020] A settling tank 21 is provided at the outlet of the front end of the feeding vibrating tank 2 on the upper p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com