Production method of fresh fish soybean sauce

A production method and technology of soy sauce, applied in the field of fresh fish soy sauce production from fresh fish and soybeans, can solve the problems of long production cycle of fish sauce, disgusting fishy smell of products, acceptance by consumers, etc., achieve retinal protection, high nutritional value, and promote digestion absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

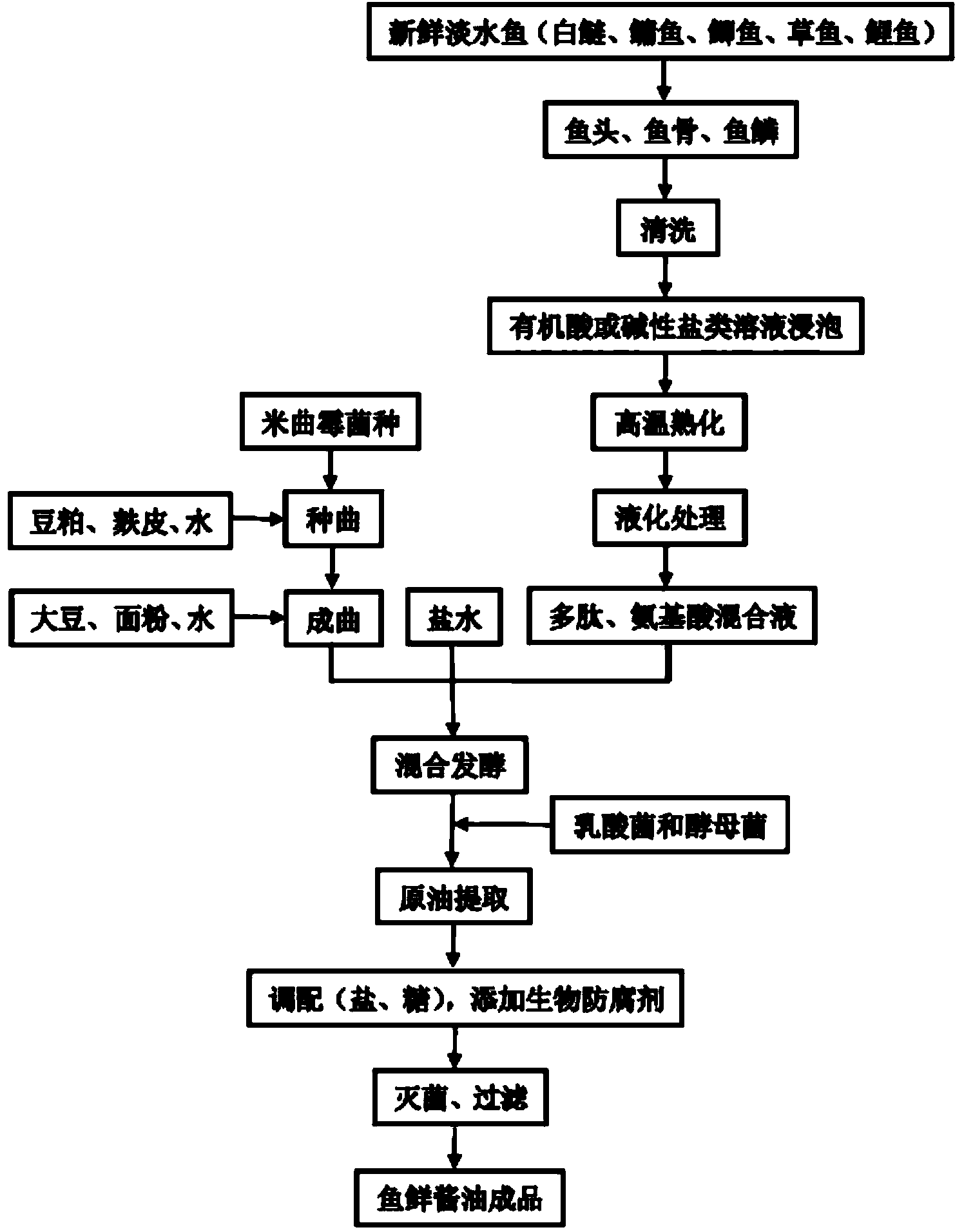

Method used

Image

Examples

specific Embodiment approach

[0019] Further illustrate the specific embodiment of the present invention below: 1, fresh fish ripening, deodorization, debitter treatment technology

[0020] ⑴Soak fish bones and meat to remove fishy smell: choose fresh freshwater fish (silver carp, bighead carp, crucian carp, grass carp or carp), dissect the fish body and divide it into fish meat, fish head, fish tail, fish bones, fish scales, internal organs and fish gills, Wherein the viscera and fish gills are used to ferment organic fertilizers, and the fish meat is used to make snack food, both of which are not included in this invention. Fish head, fish tail, fish bones and fish scales are selected as fresh fish soy sauce animal protein raw materials of the present invention, hereinafter referred to as fish bones and meat. First of all, preliminary cleaning is required. After preliminary cleaning, immerse in organic acid (acetic acid, dilute hydrochloric acid, citric acid or lactic acid, etc.) Odor components, such a...

Embodiment 1

[0031] 1. Fresh fish ripening, deodorization and debitter treatment technology

[0032] (1) Soak fish bones and meat to remove fishy smell: fresh fish heads, fish tails, fish bones and fish scales are preferred. After cleaning, soak in citric acid with a volume fraction of 1% for 20 minutes to remove the fishy smell.

[0033] ⑵Fish bones and meat are cooked to prevent raw fishy smell

[0034] After soaking and deodorizing, the fish bones and meat are steam sterilized at 121°C for 30 minutes to prevent spoilage bacteria from producing fishy smell.

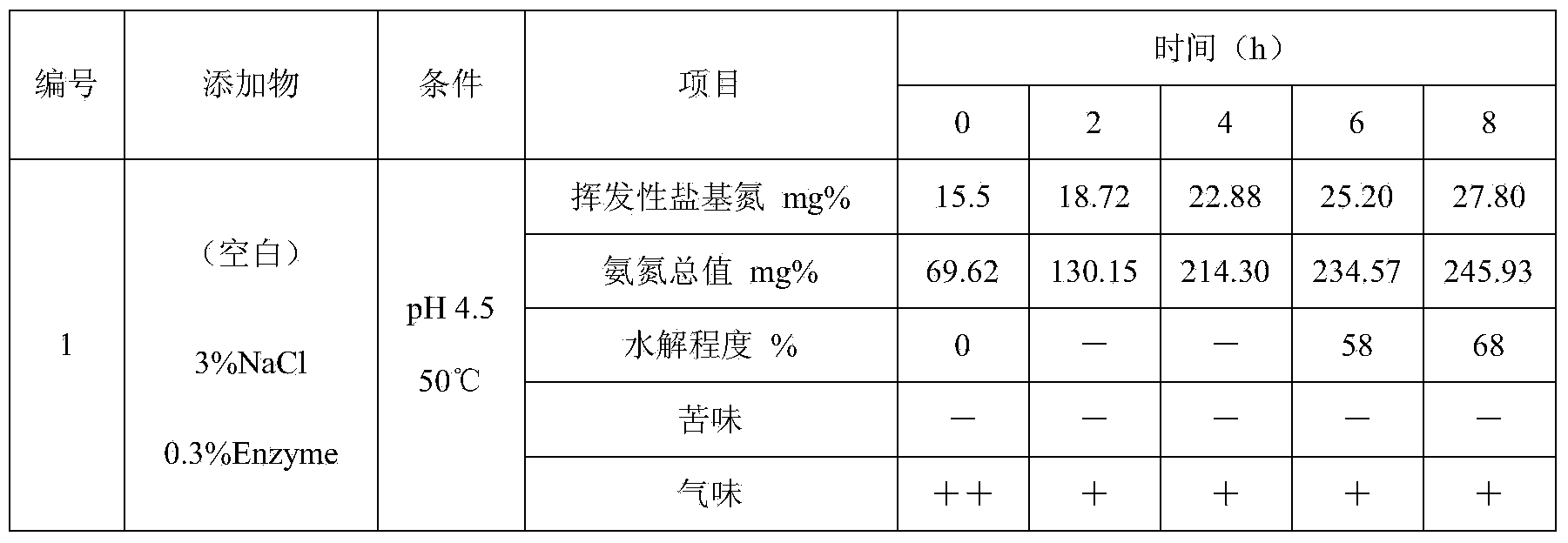

[0035] ⑶ Deodorization and debitterness of fish bone and meat liquefaction

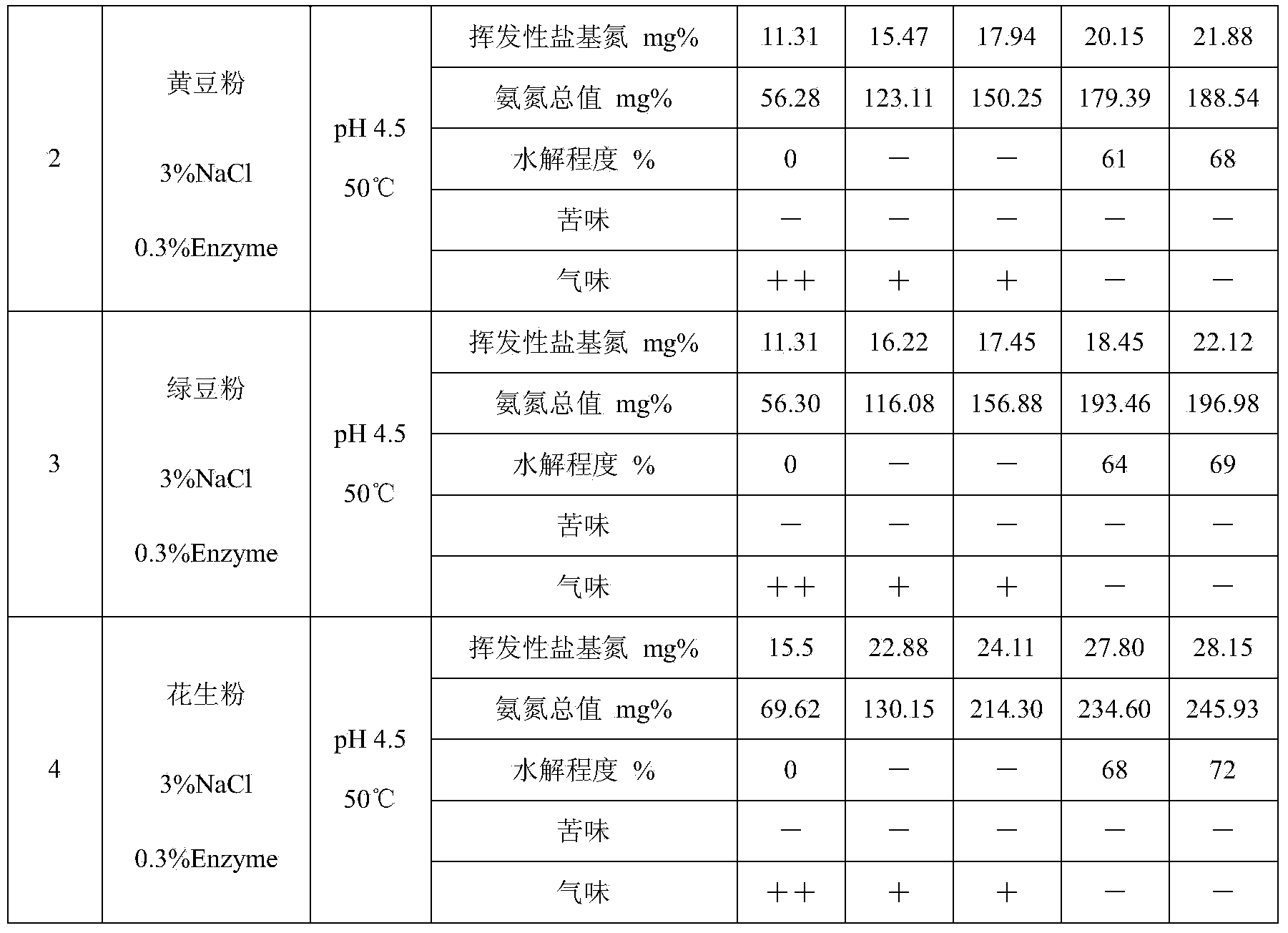

[0036] Ripe the ground fish bones and meat, in parts by weight, add 100 parts of water, 3 parts of NaCl, 5 parts of soybean powder and 0.3 part of bromelain for every 100 parts of cured fish material, at pH 4.5, temperature It is liquefied and decomposed under the condition of 50°C. When the measured DH value is between 65-80%, the liquefaction can be stopp...

Embodiment 2

[0046] 1. Fresh fish ripening, deodorization and debitter treatment technology

[0047] ⑴Soak fish bones and meat to remove fishy smell

[0048] Fresh fish heads, fish tails, fish bones and fish scales are preferred. After cleaning, soak in acetic acid with a volume fraction of 2% for 15 minutes to remove the fishy smell.

[0049] ⑵Fish bones and meat are cooked to prevent raw fishy smell

[0050] After being soaked to remove the fishy smell, the fish bone meat is steam sterilized at 121°C for 20 minutes to prevent spoilage bacteria from producing fishy smell.

[0051] ⑶ Deodorization and debitterness of fish bone and meat liquefaction

[0052] Ripe the ground fish bones and meat, in parts by weight, add 100 parts of water, 5 parts of NaCl, 8 parts of mung bean powder and 0.1 part of bromelain for every 100 parts of cured fish material, at pH 4.2, temperature It is liquefied and decomposed under the condition of 55°C. When the measured DH value is between 65-80%, the liquef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com