Composite dielectric double-layer fss structure srr metal layer ultra-thin absorbing material

A composite medium and absorbing material technology, applied in the field of absorbing materials, can solve the problems of narrow absorbing bandwidth and thick relative thickness, and achieve the effect of easy processing, low thickness and reducing radar scattering cross section.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make those skilled in the art further understand the present invention, below in conjunction with the attached Figure 1-5 The present invention will be further described.

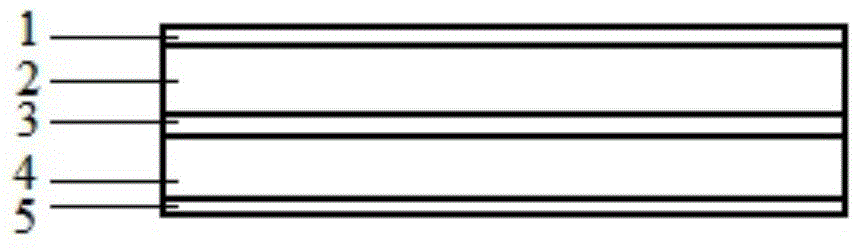

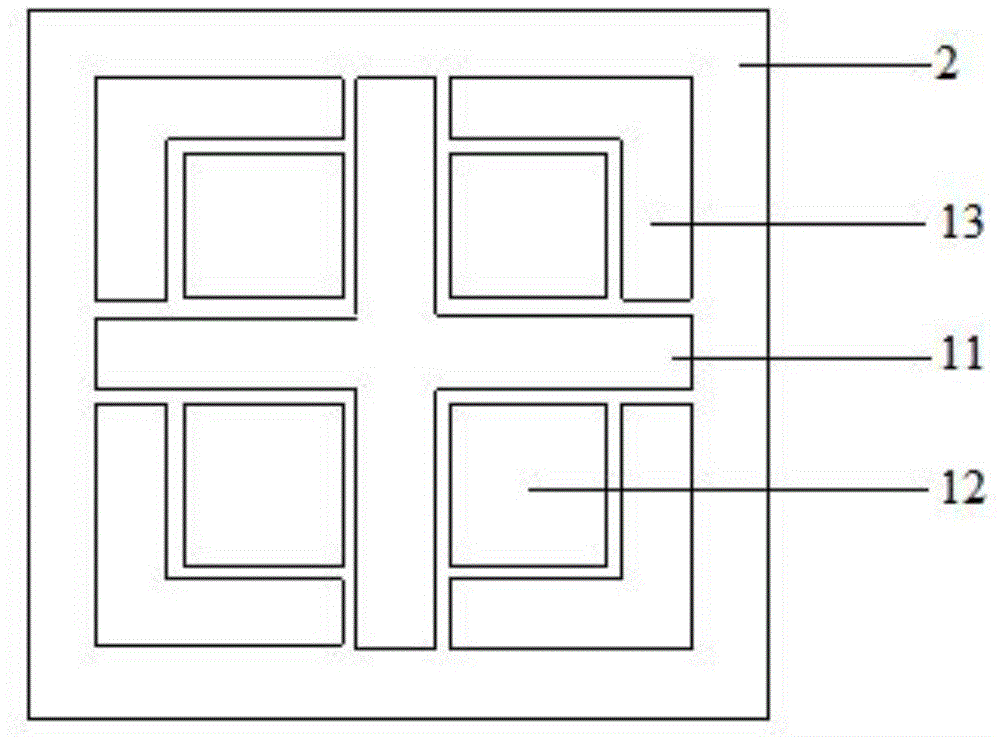

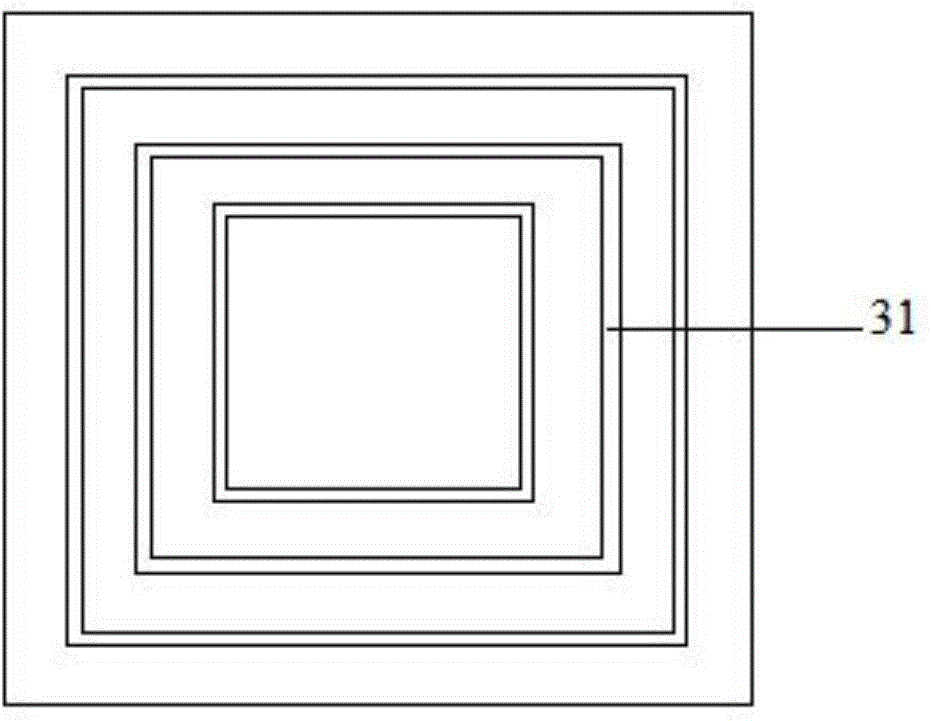

[0031] Composite dielectric double-layer FSS structure SRR metal layer ultra-thin absorbing material includes first frequency selective surface resistance layer 1, first dielectric layer 2, second frequency selective surface resistance layer 3, second dielectric layer 4 and Metal reflective layer 5; wherein, the first frequency selective surface resistance layer 1 is made up of periodically arranged carbon film patch units, and the carbon film patch unit is composed of a cross-shaped patch 11, four identical square patches 12 and four The same L-shaped patch 13 is composed of four square patches 12 and four L-shaped patches 13 symmetrically distributed relative to the center point of the cross-shaped patch 11, that is, the cross-shaped patch 11 has four identical arms, adjacent There is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com